Components of refrigeration are the lifeblood of a comfy home. Imagine a scorching summer day without a refrigerator or air conditioner. Sounds unbearable, right? In this guide, we’ll dive into the world of refrigeration, unraveling its mysteries so you can make informed decisions about your home cooling system. Let’s chill together!

Table of Contents

Basic Principles of Refrigeration

Refrigeration systems work their magic by removing heat from one place and dumping it elsewhere. There are two main types of refrigeration cycles: vapor-compression and absorption. Let’s break them down.

Vapor-compression refrigeration cycle

This is the most common type of refrigeration cycle, used in everything from household fridges to large-scale cooling systems. It has four main stages:

Evaporation

In this stage, the refrigerant absorbs heat from the surroundings and evaporates, turning into a low-pressure gas. It’s like when you’re sweating on a hot day, and the moisture on your skin evaporates, cooling you down. Neat, huh?

Compression

Next, the low-pressure gas gets compressed by the compressor, raising its temperature and pressure. Think of it like squeezing a balloon – the gas inside gets hotter, right?

Condensation

Now, the high-pressure gas enters the condenser, where it releases its heat and condenses into a high-pressure liquid. It’s similar to how water vapor in the air condenses on a cold glass.

Expansion

Lastly, the high-pressure liquid goes through an expansion device, which reduces its pressure and temperature. This process creates a cold liquid-gas mixture that enters the evaporator, and the cycle begins anew. Cool, right?

Absorption refrigeration cycle

This cycle uses heat energy to drive the refrigeration process. It’s less common but still pretty fascinating. Here’s how it works:

Absorber

The refrigerant vapor is absorbed by a liquid absorbent, creating a solution. This process generates heat, just like when you mix some substances together.

Generator

The solution is heated, causing the refrigerant to vaporize and separate from the absorbent. It’s like boiling a pot of water – the steam escapes, leaving the salt behind.

Heat exchanger

As the refrigerant vapor leaves the generator, it passes through a heat exchanger, where it releases some heat. This helps cool the vapor and improves the overall efficiency of the system.

Expansion device

The refrigerant vapor then goes through an expansion device, reducing its pressure and temperature. The now cold refrigerant enters the evaporator, and the cycle starts again. It’s all about that continuous flow!

To learn more about the basics of refrigeration, click here: Refrigeration Technology: Your Ultimate Guide to Cooling Fundamentals

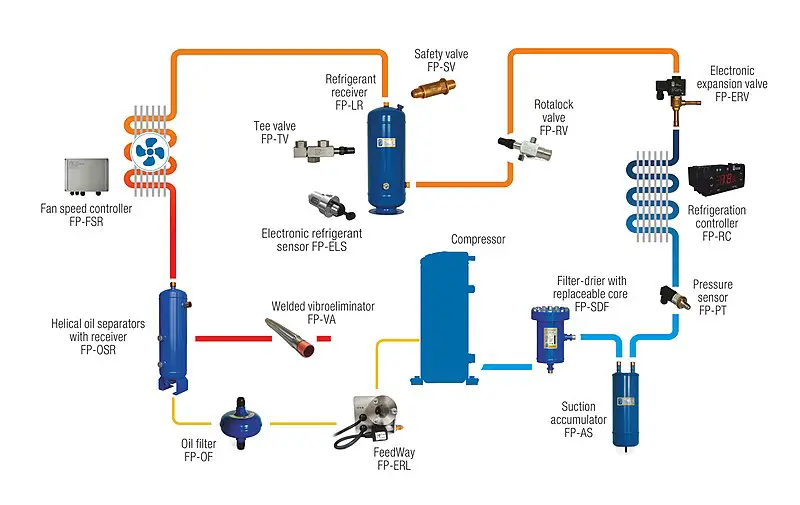

Key Components of a Refrigeration System

Now that we’ve got the basics down, let’s take a closer look at the main components that make refrigeration systems tick.

Compressor

The compressor is the heart of any vapor-compression refrigeration system. It pumps the refrigerant gas, keeping the cycle going. But did you know there are different types of compressors?

Types of compressors

There are four main types of compressors, each with its own advantages:

Reciprocating compressors:

These are like little engines, with pistons that move back and forth to compress the refrigerant. They’re reliable and easy to maintain.

Rotary compressors:

These compressors use rotating vanes or screws to compress the refrigerant. They’re compact and quiet, making them great for residential use.

Scroll compressors:

With their spiral-shaped design, these compressors are super efficient and quiet. They’re perfect for heat pumps and air conditioners.

Centrifugal compressors:

These compressors use a spinning impeller to create a high-pressure refrigerant gas. They’re ideal for large-scale cooling systems.

Compressor selection criteria

When choosing a compressor, consider factors like efficiency, noise levels, and maintenance requirements. It’s all about finding the right fit for your needs!

Condenser

The condenser is where the refrigerant releases its heat and changes back into a liquid. Like compressors, there are different types of condensers to choose from:

Types of condensers

There are three main types of condensers, each with its own benefits:

Air-cooled condensers:

These condensers use air to remove heat from the refrigerant. They’re simple and cost-effective, making them popular in residential and small commercial applications.

Water-cooled condensers:

These condensers use water to absorb heat from the refrigerant. They’re more efficient than air-cooled condensers but require a water source and additional maintenance.

Evaporative condensers:

These condensers combine the best of both worlds, using water and air to cool the refrigerant. They’re efficient and great for large cooling systems but require more maintenance than the other two types.

Condenser sizing and selection

When selecting a condenser, consider factors like efficiency, space requirements, and maintenance needs. It’s essential to choose the right size for your system to ensure optimal performance and energy savings.

Evaporator

The evaporator is where the magic happens – it’s where the refrigerant absorbs heat and evaporates, providing the cooling effect. There are different types of evaporators, each designed for specific applications:

Types of evaporators

Evaporators come in various shapes and sizes, but they can be broadly categorized into four main types:

Natural convection evaporators:

These evaporators rely on natural air circulation to distribute the cold air. They’re simple, but not as efficient as other types.

Forced convection evaporators:

These evaporators use fans to circulate air over the cooling coils, providing more even cooling. They’re great for residential and commercial applications.

Direct expansion (DX) evaporators:

These evaporators use the expansion of the refrigerant to cool the coils directly. They’re efficient and widely used in air conditioning systems.

Flooded evaporators:

These evaporators immerse the cooling coils in a pool of liquid refrigerant. They’re highly efficient and ideal for large-scale cooling systems.

Evaporator selection criteria

When choosing an evaporator, consider factors like efficiency, space requirements, and the specific cooling needs of your application. It’s all about finding the right match for your system!

Expansion Device

The expansion device plays a crucial role in the refrigeration cycle by reducing the refrigerant’s pressure and temperature. There are several types of expansion devices to choose from:

Types of expansion devices

Expansion devices come in various designs, each with its own advantages:

Capillary tubes:

These simple, low-cost devices use the refrigerant’s pressure drop to control its flow. They’re commonly used in small appliances like refrigerators and window air conditioners.

Thermostatic expansion valves (TXV):

These valves regulate the refrigerant flow based on the evaporator’s temperature. They’re efficient and suitable for a wide range of applications.

Electronic expansion valves (EEV):

These high-tech valves use electronic sensors to control the refrigerant flow. They offer precise control and improved efficiency, especially in variable-speed systems.

Float valves:

These valves maintain a constant level of liquid refrigerant in the evaporator. They’re used in flooded evaporator systems.

Expansion device selection and sizing

When selecting an expansion device, consider factors like efficiency, control accuracy, and compatibility with your system. Proper sizing is critical to ensure optimal performance and prevent issues like poor cooling or compressor damage.

Refrigerants

Refrigerants are the lifeblood of any refrigeration system. They’re responsible for absorbing, transporting, and releasing heat. But with so many options out there, how do you choose the right one?

Types of refrigerants

Refrigerants come in various forms, each with its own characteristics:

Chlorofluorocarbons (CFCs):

Once widely used, CFCs have been phased out due to their harmful effects on the ozone layer. Good riddance!

Hydrochlorofluorocarbons (HCFCs):

These refrigerants are less harmful than CFCs but are still being phased out due to their ozone-depleting potential.

Hydrofluorocarbons (HFCs):

HFCs are more environmentally friendly alternatives to CFCs and HCFCs. They have no ozone depletion potential but still contribute to global warming.

Natural refrigerants:

These refrigerants, like ammonia, carbon dioxide, and hydrocarbons, have low environmental impact and are gaining popularity in modern refrigeration systems.

Refrigerant selection criteria

When choosing a refrigerant, consider factors like environmental impact, thermodynamic properties, and safety considerations. Remember, it’s essential to use the right refrigerant for your system to ensure optimal performance and safety.

Auxiliary Components and Controls

Aside from the main components, refrigeration systems also have a variety of auxiliary components and controls that help them run smoothly and efficiently. Let’s explore some of these:

Refrigeration system controls

Controls help regulate the refrigeration system’s operation, ensuring optimal performance and energy efficiency. Some common types of controls include:

Ancillary components

Accumulators

Accumulators are essential components in refrigeration systems, designed to protect the compressor from potential damage caused by liquid refrigerant entering it. Liquid refrigerant can cause a phenomenon known as “liquid slugging,” which can damage the compressor’s mechanical parts, reduce its efficiency, and even lead to system failure.

Accumulators are typically installed between the evaporator and the compressor. They function by capturing excess liquid refrigerant before it enters the compressor. As the refrigerant mixture of vapor and liquid enters the accumulator, the liquid refrigerant settles at the bottom due to gravity, while the vapor rises to the top. The vapor then exits the accumulator and continues to the compressor. Meanwhile, the liquid refrigerant is gradually released back into the system through a metering device or an orifice, preventing it from entering the compressor in large amounts.

By effectively separating and managing liquid refrigerant, accumulators help maintain the compressor’s efficiency and reliability, ultimately prolonging the life of the refrigeration system.

Receivers

Receivers are containers used in refrigeration systems to store excess refrigerant and ensure a constant supply for the system. They are particularly important in systems that operate under varying loads or use multiple evaporators with different pressure levels.

Receivers are typically installed between the condenser and the expansion device. As the refrigerant leaves the condenser, it enters the receiver, where it is stored until needed by the system. The receiver acts as a buffer, providing a reservoir of refrigerant to accommodate fluctuations in the system’s cooling demand. This ensures that the refrigerant flow remains consistent, maintaining stable temperatures and preventing issues like poor cooling or evaporator icing.

In addition to providing a constant supply of refrigerant, receivers also play a role in system maintenance. They offer a convenient location for refrigerant storage during service or repair, making it easier to manage and recover refrigerant without releasing it into the environment.

Overall, receivers contribute to the efficient and reliable operation of refrigeration systems, helping to maintain optimal performance and supporting system maintenance efforts.

These additional components help improve the system’s performance, reliability, and safety. Some examples include:

System Design and Optimization

Designing and optimizing a refrigeration system is all about striking the perfect balance between performance, efficiency, and reliability.

Energy efficiency considerations

When designing a refrigeration system, it’s essential to consider energy efficiency. Some strategies for improving efficiency include:

Maintenance and troubleshooting

Proper maintenance and troubleshooting are critical for ensuring the longevity and performance of your refrigeration system. Some key aspects to consider include:

Conclusion

Refrigeration systems are essential for modern life, keeping our food fresh, our homes comfortable, and our industries running smoothly. By understanding the components of refrigeration and their functions, you can make informed decisions about the design, maintenance, and optimization of these critical systems.

The role of refrigeration in the modern world

From preserving food to keeping us cool on hot summer days, refrigeration plays a vital role in our daily lives. It has revolutionized food storage, transportation, and countless industries, making modern life possible.

Future trends and innovations in refrigeration technology

As technology advances and our understanding of refrigeration systems grows, we can expect exciting innovations and trends, like environmentally friendly refrigerants, smart controls, and increasingly energy-efficient designs. The future of refrigeration is looking cool!