Did you know that absorption chiller manufacturers are transforming the way we cool our buildings and industries? That’s right! These manufacturers produce a unique type of chiller that uses heat energy instead of mechanical energy, making them a go-to choice for those seeking energy-efficient and environmentally friendly cooling solutions.

Table of Contents

Introduction

Absorption chillers are fascinating pieces of machinery. They’re like a magic trick in the world of HVAC, providing cooling by using heat. Sounds paradoxical, doesn’t it? And who makes these marvelous machines? That’s where absorption chiller manufacturers come into play, the wizards behind the curtain.

Understanding Absorption Chillers

Absorption chillers, or absorptive chillers as they’re sometimes known, are more than just a fancy name. They are cooling units that function by absorbing heat energy – hence the name. But how does this heat absorption process work?

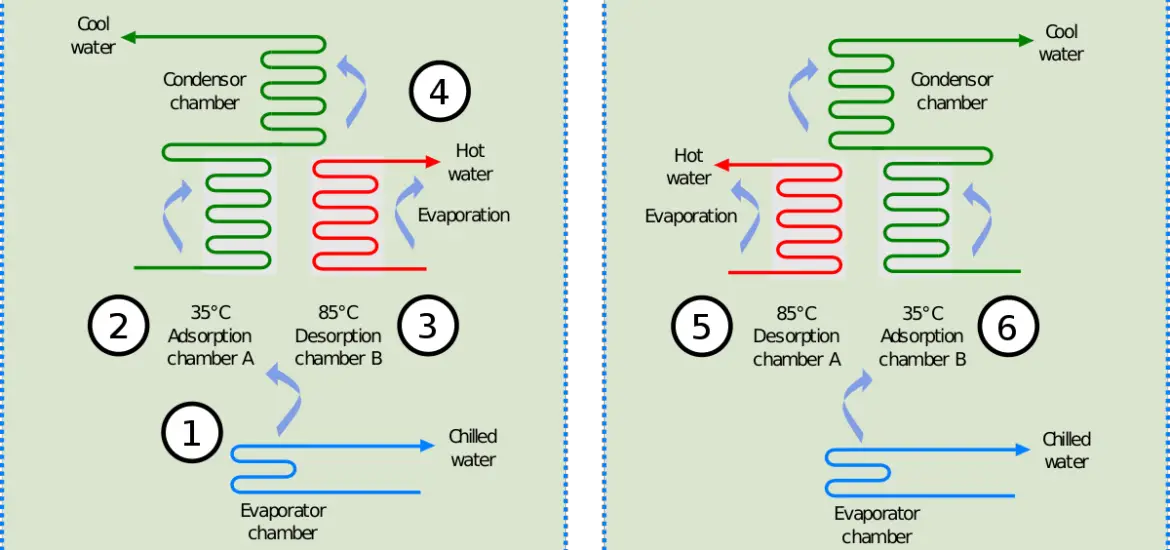

Essentially, these chillers consist of four main components: the evaporator, absorber, generator, and condenser. When water in the evaporator turns into vapor, it gets absorbed by a solution in the absorber. This solution then travels to the generator, where heat is applied to separate the water vapor. The vapor then travels to the condenser, releases its heat and turns back into a liquid. This liquid goes back to the evaporator, and the process starts all over again. Sounds complex, doesn’t it? But don’t worry, the guys who make these machines know what they’re doing!

Now, there are two main types of absorption chillers – single-effect and double-effect. The single-effect chillers use one generator and one condenser, whereas the double-effect chillers use two, making them more efficient. But regardless of the type, all absorption chillers follow the same basic principle of using heat to create a cooling effect.

For more articles on absorption refrigeration, click here.

The Absorption Chiller Manufacturing Process

Ever thought about how these absorption chillers come to life? It’s a meticulous process that requires a lot of planning, precision, and quality control. Let’s walk through the steps together, shall we?

The manufacturing process begins with the design and planning stage, where engineers create detailed plans for each component of the chiller. Then comes the material procurement stage, where the necessary materials are sourced and gathered.

Next, we have the assembly and production stage, where the chillers are physically put together. Lastly, there’s the testing and final inspection stage, where each chiller is thoroughly checked to ensure it meets all quality and safety standards. A lot goes into making these machines, doesn’t it?

Stage 1: Design and Planning

The design and planning stage is where the magic begins. It’s where the engineers come up with the blueprint for the chiller. They have to take into account the type of chiller, its capacity, the environment it’ll be used in, and much more. They basically have to foresee how the chiller will perform in the real world and design it accordingly. Sounds like quite a challenge, right? But that’s what makes these engineers so exceptional.

Stage 2: Material Procurement

Once the design is ready and approved, it’s time to gather the materials. Now, this isn’t as simple as popping down to the local hardware store. Oh no! These materials are often sourced from all over the world. Different metals, plastics, and chemicals, each with their specific properties, all chosen for a specific role within the chiller. It’s a global effort to build these machines!

Stage 3: Assembly and Production

With the design in hand and materials at the ready, it’s time to assemble the chiller. This stage is like a well-choreographed dance, with each component meticulously put together according to the design. And the best part? The entire process is overseen by quality control, ensuring that each chiller is built to perfection. Can you imagine the level of precision and attention to detail required here? It’s truly remarkable.

Stage 4: Testing and Final Inspection

And finally, once the chiller is assembled, it’s time for the final act: testing and inspection. Now, this isn’t just a quick glance over. Each chiller is rigorously tested under different conditions to ensure it performs as expected. Any glitches or hiccups? Back it goes for adjustments. Only once it passes all the tests and checks, it’s ready to head out into the world. It’s like a final exam for the chiller, and only the top students get to graduate!

Key Players in Absorption Chiller Manufacturing

So, who are the geniuses behind these innovative machines? Let’s take a look at some of the major players in the absorption chiller manufacturing industry.

Trane Technologies

Trane is a global manufacturer of heating, ventilating, and air conditioning (HVAC) systems and building management systems and controls. The company’s absorption chillers offer an environmentally friendly option for specific commercial and industrial applications.

Carrier Global Corporation

Carrier is a leading global provider of innovative HVAC, refrigeration, fire, security, and building automation technologies. They offer absorption chillers in their commercial HVAC product range.

Johnson Controls

Johnson Controls is a multinational conglomerate that produces fire, HVAC, and security equipment for buildings. Their absorption chillers are part of their offerings for energy-efficient HVAC solutions.

Challenges and Future Trends in Absorption Chiller Manufacturing

Like any industry, absorption chiller manufacturing faces its own set of challenges. But with challenges come opportunities, right? And there are also some pretty exciting trends on the horizon. So, what’s cooking in the absorption chiller world?

Current Challenges

Some of the key challenges in the industry include economic factors, environmental concerns, and technological hurdles. For instance, the high initial cost of absorption chillers can be a deterrent for some customers.

Then there’s the need to comply with strict environmental regulations. And let’s not forget the ongoing quest for greater efficiency and performance. But you know what? These manufacturers are not ones to back down from a challenge!

Future Trends

Looking ahead, there are several trends that could shape the future of absorption chiller manufacturing. For instance, the drive towards sustainable and energy-efficient solutions is expected to continue, pushing manufacturers to innovate even more. Then there’s the potential of new technologies, such as IoT and AI, to revolutionize the way these chillers are monitored and maintained. Exciting times ahead, wouldn’t you say?

Conclusion

So, there you have it, a peek into the world of absorption chiller manufacturers. These companies are not just making machines; they’re pushing the boundaries of technology, striving for sustainability, and, in the process, transforming the way we cool our spaces. And as we look to the future, one thing’s for sure: absorption chillers are here to stay, and the manufacturers behind them will continue to play a crucial role in shaping a cooler, more sustainable world.