Boiling point of refrigerants – doesn’t it sound like something you’d learn in a science class you never wanted to take? Well, guess what? It’s a cool topic (pun intended) and super important! In this article, we’ll get to know why the boiling point of refrigerants is so darn important.

Table of Contents

Overview of Boiling Point of Refrigerants

So, refrigerants are like the lifeblood of your AC or refrigerator. And the boiling point is that temperature where they say, “Okay, I’m ready to change from liquid to gas!” – and that’s when the cooling begins. It’s kind of like when water boils to make your coffee – but way, way cooler.

The Importance of Understanding the Boiling Point of Refrigerants

Why should you care about the boiling point of refrigerants? Imagine if the refrigerant in your AC had a boiling point hotter than the Sahara Desert. How well do you think that AC will cool your room? Not very! Knowing the boiling point helps technicians, and smarty-pants like you, to understand how efficiently refrigerants can do their job.

Importance of the Boiling Point in Refrigerants

Picture a snowman. If you put him in warm weather, he melts, right? It’s similar with refrigerants – their boiling points tell us the temp at which they’ll switch from liquid to gas, which is what makes the cooling happen!

Role of Boiling Point in Refrigeration Cycles

Did you know your fridge and AC have a little cycle they go through, kinda like a dance? The boiling point is the star of the show. It’s when the refrigerant absorbs heat and changes its state, making sure your leftover pizza and your room stay cool.

Types of Refrigerants and their Boiling Points

Refrigerants come in various types, each with their unique boiling points. The boiling point defines how efficiently these refrigerants do their cooling job, from the classic CFCs and HCFCs to the modern HFCs and natural alternatives.

Chlorofluorocarbons (CFCs)

Back in the day, CFCs were the big kahunas of refrigerants. But, they were up to no good – depleting the ozone layer like nobody’s business. The boiling points of CFCs are generally pretty low, which made them efficient but, yeah, not so eco-friendly.

Commonly Used CFCs and their Boiling Points

R-12, that’s the notorious one. It has a boiling point of -21.6°F. It used to be in every car and kitchen till people realized how much it’s harming Mother Earth. R-11 is another one, with a boiling point of 74.7°F. Now, though, these bad boys are mostly out of use.

Hydrochlorofluorocarbons (HCFCs)

So, the world got wise to CFCs and decided to go for the lesser evil – HCFCs. Still not great for the ozone, but better. These fellas have boiling points that also range in the low to moderate region.

Widely Used HCFCs and their Boiling Points

Ever heard of R-22? It’s an HCFC with a boiling point of -40.8°F. It’s been used a lot, especially in older AC units, but is now being phased out because we’ve got even better options.

Hydrofluorocarbons (HFCs)

Enter the new-age refrigerants – the HFCs. They said “Bye, bye” to chlorine, which means they’re safe for the ozone layer. Their boiling points? Mostly low, which makes them efficient at cooling.

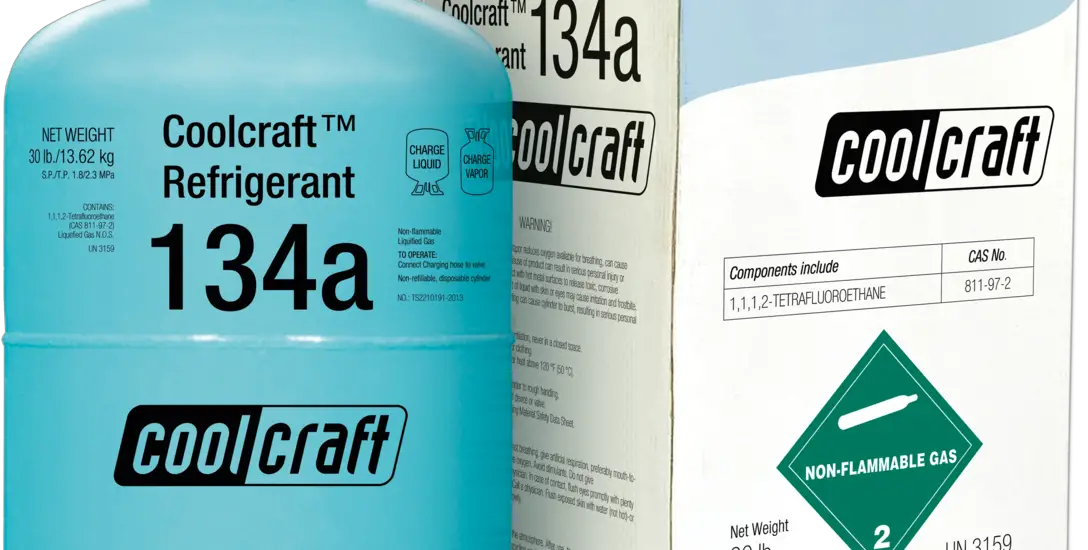

Popular HFCs and their Boiling Points

The cool kid on the block these days is R-134a, with a boiling point of -14.9°F. It’s used in a lot of places, from your car’s AC to your home’s refrigerator.

Natural Refrigerants

Natural refrigerants are Mother Nature’s way of keeping it cool. They have varying boiling points and the bonus point? They’re super eco-friendly!

Key Natural Refrigerants and their Boiling Points

Good ol’ Ammonia, known as R-717 in the biz, has a boiling point of -28°F. Then there’s CO2 (R-744), which is really, really cool (okay, it’s actually supercritical at 87.8°F).

Factors Influencing the Boiling Point of Refrigerants

Like a detective novel, many factors can alter the plotline of a refrigerant’s boiling point. From its molecular structure and atmospheric pressure to the purity of the refrigerant itself, these factors significantly impact its boiling point.

Molecular Structure

How a refrigerant’s built, molecule by molecule, affects its boiling point. Just like building a house with bricks or straw would affect how it stands up to the Big Bad Wolf.

How Molecular Structure Affects the Boiling Point of Refrigerants

Every molecule has its vibe. The shape, size, and composition of refrigerant molecules determine how they interact with heat and pressure, ultimately affecting their boiling points.

Atmospheric Pressure

Pressure can make anyone sweat, even refrigerants! The amount of atmospheric pressure they’re under can change their boiling point. It’s all about balance, you see.

The Impact of Atmospheric Pressure on the Boiling Point of Refrigerants

Think about a pressure cooker – it increases the boiling point of water, right? Similarly, changes in pressure can make refrigerants boil at higher or lower temperatures. Isn’t science fun?

Refrigerant Purity

Refrigerants like to keep it pure. Any impurities can mess with their boiling point – kind of like adding salt to water.

The Influence of Purity on the Boiling Point of Refrigerants

A pure refrigerant behaves predictably, like a well-rehearsed waltz. But throw in some impurities, and suddenly it’s a mosh pit, with a potential change in boiling point.

Check out these other related articles…

Refrigerant Pressures: Your Ultimate Guide to Measure, Interpret and Handle Them Safely

Top Up Refrigerant Gas: Your Ultimate Guide for Cooling Efficiency

Refrigerant Orifice: Your Key to Understanding and Mastering Refrigeration

Reclaiming Refrigerant: Your Complete Guide

Best Refrigerant for Low-Temperature Applications: A Comprehensive Guide

How Boiling Point Affects Refrigerant Selection

The boiling point isn’t just a number on a chart; it’s a critical factor in choosing the right refrigerant for any given application. It influences everything from climate adaptability and energy efficiency to the very design of cooling systems.

Relevance of Boiling Point of Refrigerants in Different Climate Zones

Would you wear a fur coat to a beach? Heck no! Similarly, choosing a refrigerant with the right boiling point for your climate is crucial.

Boiling Point Considerations in Hot Climates

In hot climates, refrigerants need to work extra hard to beat the heat. Choosing one with a lower boiling point can help maximize efficiency.

Boiling Point Considerations in Cold Clilamtes

On the flip side, in cold climates, a refrigerant with a higher boiling point might do the trick, avoiding the risk of it becoming too cold to vaporize.

Boiling Point and Energy Efficiency

It’s not just about saving the planet, it’s also about saving your wallet. A refrigerant with the right boiling point can make your AC or fridge more energy-efficient.

How a Low Boiling Point Contributes to Energy Efficiency

A lower boiling point means less energy is needed to transform the refrigerant from liquid to gas, leading to more efficient cooling. It’s like getting more bang for your buck.

How a High Boiling Point Affects Energy Consumption

With a high boiling point, more energy is needed to kickstart the cooling process, which can make your system less energy efficient. It’s like running a marathon just to get a cup of coffee – too much effort!

Boiling Point and System Design

When designing a cooling system, engineers keep the boiling point of the refrigerant in mind. It’s like choosing the right type of tires for your car – it affects performance!

Influence of Boiling Point on the Design of HVAC Systems

The right refrigerant with the right boiling point allows the HVAC system to operate optimally. It’s like putting the right key in the lock – everything just works smoothly.

Safety Considerations Related to the Boiling Point of Refrigerants

With power comes responsibility, and refrigerants are no different. Their boiling point can impact system safety, potentially leading to risks such as overheating or system failure if not carefully considered.

Understanding the Safety Risks

Like any chemical, refrigerants need to be handled with care. Their boiling points play a key role in maintaining safety.

Boiling Point and Risk of Overheating

A refrigerant with a high boiling point can lead to a risk of overheating. It’s like running your car engine too hot – things can go south real quick!

Boiling Point and Risk of System Failures

On the other hand, a low boiling point can lead to the system getting too cold, causing it to freeze and fail. It’s like being so cold you can’t move – not a good scenario.