You know, condenser heat exchangers are a marvel of engineering that perform an essential role in many industries. However, have you ever wondered how they work or why they are so vital? Don’t worry; we’ve got you covered. In this article, we’ll delve deep into the world of condenser heat exchangers, revealing all the juicy details you need to understand their importance.

Table of Contents

Overview of Condenser Heat Exchangers

Condenser heat exchangers are critical devices used to transfer heat between different mediums. They play a vital role in a wide range of industries, ensuring optimal temperature regulation for a myriad of processes.

Definition and Function

A condenser heat exchanger, in essence, is a device that efficiently transfers heat between two or more fluids at different temperatures. It’s like an unseen conductor in an orchestra, directing heat from one player (fluid) to another, without mixing them up. You can find these devices working their magic in places like power plants, refrigeration systems, and air conditioning units.

Basic Principle of Operation

So, how does the magic happen? Well, a condenser heat exchanger operates on the principle that heat moves from a hot substance to a colder one. It’s like a busy, bustling airport, where heat is the traveler always on the move, and the exchanger is the airport directing traffic.

Key Components

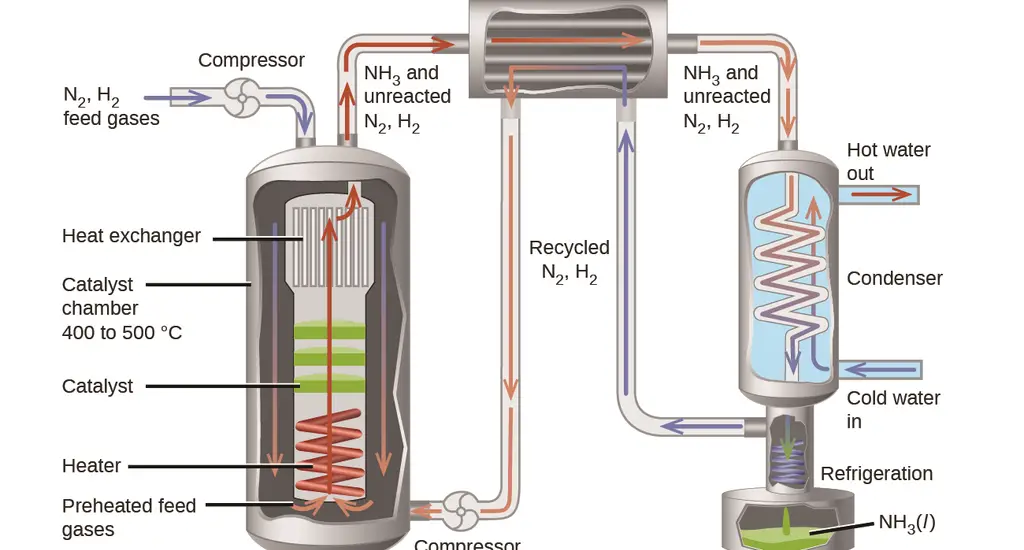

The guts of a condenser heat exchanger might seem complicated, but once you get to know them, it’s like getting to know the characters in a novel. Each part plays its role, from the tubes that transport the fluids to the shell that houses the whole operation.

Importance of Condenser Heat Exchangers in Various Applications

Condenser heat exchangers are akin to the heart of many industries. They regulate temperature in HVAC systems, recycle waste heat in power plants, and keep our food cold in refrigeration systems. You might not see them, but they’re working hard behind the scenes to keep our world comfortable and energy-efficient.

Detailed Analysis of Condenser Heat Exchangers

Condenser heat exchangers are fascinating pieces of engineering, coming in various types each with its unique mechanism. Delving into their detailed analysis can unveil their individual peculiarities and functional distinctions.

Various Types of Condenser Heat Exchangers

These marvels of heat transfer technology come in several flavors, each designed to best suit its purpose. From shell and tube to plate or air-cooled, each type has its unique setup and working principle.

Shell and Tube Heat Exchangers

Imagine a beehive, buzzing with activity. That’s a shell and tube heat exchanger. It’s made up of a series of tubes packed into a shell. The heat transfer occurs as one fluid flows inside the tubes while another flows outside the tubes but inside the shell.

Plate Heat Exchangers

A plate heat exchanger is like a neat stack of pancakes. It’s composed of thin plates stacked together, allowing heat to be exchanged between fluids flowing in the channels created by the plates.

Air-cooled Heat Exchangers

Think of an air-cooled heat exchanger as a cool, breezy day at the beach. Instead of using a second fluid, these exchangers use air to remove heat. They’re often used in systems where water is scarce or where it’s important to avoid liquid waste.

Working Mechanism of Different Types

Now that you know the characters in our story, let’s explore how they go about their tasks.

Shell and Tube Heat Exchangers

Inside a shell and tube heat exchanger, you’ve got one fluid running through the tubes, getting hot (or cold) under the collar. Meanwhile, the other fluid flows over those tubes, soaking up (or offloading) heat. It’s a finely choreographed dance, with heat as the ever-moving partner.

Plate Heat Exchangers

Plate heat exchangers play out a more intricate dance. The fluids flow through alternating channels created by the plates, each dancing cheek-to-cheek with the heat, either gaining or losing it.

Air-cooled Heat Exchangers

In an air-cooled heat exchanger, the dance of heat is more of a solo act. The fluid releases its heat to the air passing over the tubes, similar to how you might cool off by standing in front of a fan on a hot day.

The Science Behind Condenser Heat Transfer

Heat transfer in condensers isn’t magic, but pure science. It’s about the chat between the hot and the cold, the endless quest for equilibrium, and the critical role played by mediums like coolants in this process.

The Concept of Heat Transfer in Condensers

Heat transfer in condensers is no different from a chat between two friends. Heat (the chattiest friend) is always eager to share its energy with its less energetic pal (the cooler fluid), aiming for an equilibrium where they both have the same energy level.

Understanding the Modes of Heat Transfer

Heat transfer isn’t a one-size-fits-all process. It dances between modes – conduction, convection, and radiation, each with its own set of rules and each playing a unique role in the operation of condenser heat exchangers.

Conduction

Conduction is like a game of telephone. It happens when heat is passed directly from one particle to another. Picture holding one end of a metal rod over a fire. Soon enough, you’ll feel the heat at your end as it travels along the rod.

Convection

Convection is more of a merry-go-round ride. It involves the movement of the fluid itself. You see it when you boil water—the hot water rises, and the cooler water descends, creating a continuous cycle of heat exchange.

Radiation

Radiation is the long-distance caller in the heat transfer world. It doesn’t need a medium to travel; it moves in the form of electromagnetic waves. It’s like the warmth you feel from the sun, even though it’s millions of miles away.

The Role of Coolants in Heat Transfer

Imagine if you had an assistant to help you with your work. That’s what a coolant does in a condenser heat exchanger. It assists in the heat transfer process, either absorbing or releasing heat to keep the system at the right temperature.

Check out these other related articles…

Evaporator Coil vs Condenser Coil: Ultimate Comparison

Condenser Coil in Refrigerator: Your Ultimate 411 Guide

Dirty Condenser Coil Symptoms: Comprehensive 411 Guide

Condenser Heat Pump: Your Comprehensive Guide

Condenser and Evaporator: The Ultimate 411 Guide

Maintenance and Efficiency in Condenser Heat Exchangers

Maintaining a condenser heat exchanger is more than a routine task; it’s a vital step toward ensuring its efficiency and longevity. Proper upkeep can prevent common issues and keep it running like a well-oiled machine.

Importance of Regular Maintenance

Like a car, a condenser heat exchanger needs regular maintenance to keep running smoothly. Neglect can lead to issues like decreased efficiency or damage, which might cost you a pretty penny in the long run.

Common Issues and Their Solutions

While condenser heat exchangers are incredibly useful, they aren’t without their quirks and troubles. From fouling to corrosion and leaks, various issues can creep up, but thankfully, there are solutions to keep them in check.

Fouling

Fouling is like the traffic jam of heat exchangers. It’s the buildup of materials on the heat transfer surface, slowing down the flow of heat. Regular cleaning can help prevent this issue.

Corrosion

Corrosion is the arch-nemesis of many metal components, and heat exchangers are no exception. It’s like an apple turning brown—it eats away at the material over time. Using corrosion-resistant materials and protective coatings can help keep corrosion at bay.

Leaks

Leaks in a heat exchanger can be as troublesome as a dripping faucet, wasting valuable resources and leading to efficiency losses. Regular inspections and prompt repairs can nip this problem in the bud.

Measures to Enhance Efficiency

Keeping your condenser heat exchanger in tip-top shape isn’t just about preventing problems, it’s also about making it run as efficiently as possible. It’s like fine-tuning a musical instrument for the best performance. Strategies could include using higher-performance materials, optimizing flow rates, or improving heat transfer surfaces.

Future Trends in Condenser Heat Exchanger Technology

Just like the ever-evolving landscape of technology, condenser heat exchanger technology is also constantly advancing. Here’s a sneak peek at what’s coming down the pipeline.

Advances in Material Science

Material science is like the fashion industry of engineering, always coming up with new and improved styles—or in this case, materials. New materials are being developed that can resist corrosion, withstand higher temperatures, and enhance heat transfer rates, making condenser heat exchangers even more effective.

Energy Efficiency Innovations

With the world increasingly focused on energy efficiency, innovations in condenser heat exchanger technology are following suit. Think of it as switching from a gas-guzzling vehicle to an electric car. New designs and processes are being developed to make heat exchangers more energy-efficient and environmentally friendly.

Development in Heat Transfer Techniques

Imagine if we could develop a new dance move that revolutionizes the way people dance. That’s what’s happening in the field of heat transfer techniques. By exploring new ways to move heat around, researchers are unlocking new levels of performance in condenser heat exchangers.