COP of vapor compression refrigeration cycle – sounds like a mouthful, right? But don’t worry, we’re here to break it down for you, homeowner style. With climate change raising temperatures, staying cool at home is more important than ever. So, let’s dive into this cool technology that keeps our homes comfy and our food fresh.

Table of Contents

Definition and Importance of Vapor Compression Refrigeration Cycle

First off, what is the vapor compression refrigeration cycle? In simple terms, it’s the process that makes your fridge, freezer, and air conditioner work. It’s all about heat transfer, getting rid of heat from inside your home or appliance and dumping it outside. Pretty neat, huh?

Basic Concept and Components Involved

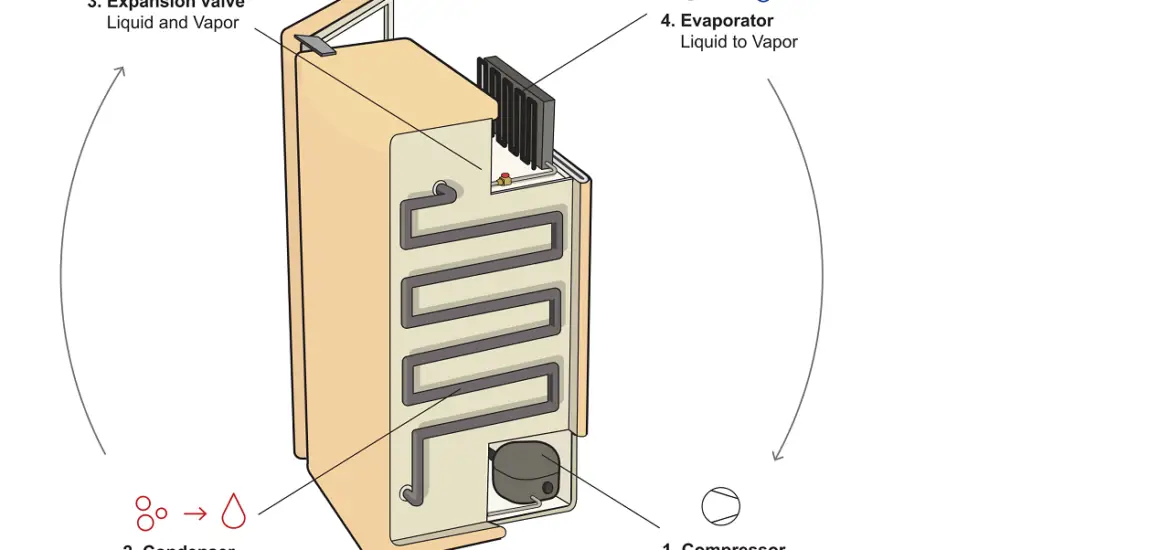

There are four main components in this process: the compressor, condenser, expansion device, and evaporator. They work together in harmony to make the magic happen. The refrigerant, a special fluid, cycles through these components and changes from gas to liquid and back again. It’s like a never-ending dance of heat transfer!

Applications of Vapor Compression Refrigeration Cycle

Besides keeping your home cool and food fresh, this process is used in many other applications like industrial refrigeration, heat pumps, and even ice rinks. Can you imagine life without it? No ice-cold drinks on a hot summer day? No thank you!

Overview of COP of Vapor Compression Refrigeration Cycle

Now, let’s talk about COP, or Coefficient of Performance. It’s a measure of how efficient your cooling system is – basically, how much cooling you get for the energy you put in. The higher the COP, the more efficient your system is, and the lower your energy bills will be. Sounds good, right?

Definition of COP

Think of COP like a report card for your cooling system. It’s calculated by dividing the amount of cooling provided (in BTUs or watts) by the energy consumed (in watts). The higher the number, the better the grade.

Factors Affecting COP

So, what affects the COP? Factors like the type of refrigerant used, the efficiency of the components, and even the outdoor temperature can impact it. But don’t worry, we’ll get into the nitty-gritty of how to improve your system’s efficiency later on.

COP of Vapor Compression Refrigeration Cycle – Theoretical Aspects

Let’s put our nerd glasses on and explore the science behind the vapor compression refrigeration cycle. Don’t worry, we’ll keep it simple and relatable.

Vapor Compression Refrigeration Cycle Equations

Remember learning about the first law of thermodynamics in school? It’s all about energy conservation. Well, that same principle is applied to the refrigeration cycle. We can use energy balance equations for each component to derive the theoretical COP. But let’s not get lost in equations – just know that there’s solid science behind it all.

First Law of Thermodynamics and its Application in Refrigeration Cycle

Energy Balance Equations for each Component

For each component in the cycle, we have an energy balance equation that helps us understand how much energy is used and transferred. These equations are essential for calculating the theoretical COP, which tells us the maximum efficiency we can expect from our cooling system.

Theoretical COP Derivation

By combining the energy balance equations, we can derive the theoretical COP. This gives us a benchmark for how efficient our cooling system could be under ideal conditions. But remember, real-life is rarely ideal, so let’s keep our expectations realistic!

Assumptions and Simplifications

Now, these equations and the theoretical COP are based on some assumptions and simplifications. Let’s take a quick look at them.

Ideal Cycle Assumptions

The ideal cycle assumes that there are no energy losses and that everything works perfectly. That means components like the compressor and heat exchangers are 100% efficient. We all know that’s not the case in reality, but these assumptions help us understand the fundamentals.

Limitations and Deviations from Real-world Scenarios

So, what happens when we leave the ideal world and enter the real one? Energy losses, inefficiencies, and other factors come into play, causing deviations from the theoretical COP. But don’t lose hope! There are ways to improve your system’s efficiency and get closer to that ideal performance.

Read our other detailed articles on vapor compression – Vapor Refrigeration: Easy Guide to Keeping Things Chill

Vapor Compression Refrigeration Efficiency

Now that we’ve covered the basics, let’s explore the factors affecting the efficiency of your cooling system and how to improve it.

Factors Affecting Vapor compression Refrigeration Efficiency

There are several factors that can impact the efficiency of your vapor compression refrigeration system. Let’s dive in!

Type of Refrigerant Used

The choice of refrigerant can make a difference in your system’s efficiency. Some refrigerants perform better than others under specific conditions, so it’s essential to choose the right one for your needs.

Compressor Efficiency

The compressor is the heart of the cooling system, and its efficiency plays a vital role in overall performance. If your compressor is running inefficiently, it can drag down your system’s COP.

Heat Exchanger Efficiency

Heat exchangers, like the condenser and evaporator, are also crucial for efficiency. They transfer heat between the refrigerant and the environment, so any inefficiencies here can impact your system’s performance.

Expansion Device Efficiency

The expansion device, which controls the flow of refrigerant between high and low-pressure sides, also affects efficiency. A well-designed expansion device can help optimize your system’s COP.

Methods to Improve Efficiency

Now that we know the factors affecting efficiency let’s look at some ways to improve it.

Optimization of Component Design

By optimizing the design of components like the compressor, heat exchangers, and expansion device, we can improve the overall efficiency of the system. This might involve using better materials, tweaking the design, or even upgrading to more advanced components.

Utilizing Advanced Refrigerants

Switching to more advanced refrigerants with better performance characteristics can also help improve efficiency. Some newer refrigerants are designed to be more environmentally friendly while still providing excellent cooling performance.

Implementing Control Systems for Better Performance

Adding smart control systems to your cooling system can help optimize its performance and efficiency. These systems can monitor and adjust various parameters in real-time, ensuring your system always operates at its best.

Vapor Compression Refrigeration Cycle Efficiency – Practical Aspects

Let’s take a look at the real-world considerations for COP and efficiency in vapor compression refrigeration systems.

Real-world COP and Efficiency Considerations

As we mentioned earlier, real-life conditions can cause deviations from the theoretical COP. So, what are the factors causing these deviations, and how do real-world efficiency values compare?

Factors Causing Deviations from Theoretical COP

In the real world, factors like component inefficiencies, energy losses, and varying operating conditions can cause deviations from the theoretical COP. For example, outdoor temperature fluctuations can affect your system’s efficiency and performance.

Real-world Efficiency Values and Comparisons

Despite these deviations, modern cooling systems can still achieve impressive efficiency levels. While they may not reach the theoretical COP, they’re continually improving thanks to advancements in technology and design.

System Optimization for Improved COP

There are several techniques that can be applied to optimize your cooling system for better COP and efficiency.

Multi-stage Compression and Intercooling

Multi-stage compression and intercooling can help improve the efficiency of your system by reducing the work done by the compressor. This technique involves compressing the refrigerant in stages and cooling it between each stage, which helps reduce energy consumption.

Economizer and Subcooling Techniques

Economizers and subcooling techniques can also help improve efficiency by making better use of the refrigeration cycle’s available cooling capacity. These methods involve using additional heat exchangers to extract more cooling from the refrigerant, resulting in improved performance.

Advanced Control Strategies

As we mentioned earlier, implementing advanced control strategies can help optimize your system’s performance in real-time. These strategies can adjust various parameters based on current conditions, ensuring your system always operates at peak efficiency.

Challenges and Future Developments in Vapor Compression Refrigeration Cycle Efficiency

Finally, let’s explore some of the challenges and future developments that could impact vapor compression refrigeration cycle efficiency.

Environmental Concerns and Regulations

Environmental concerns, such as ozone depletion and global warming potential, have led to stricter regulations on refrigerants. This has driven the development of more eco-friendly refrigerants and innovative cooling technologies.

Ozone Depletion and Global Warming Potential of Refrigerants

Some older refrigerants, like CFCs and HCFCs, have been phased out due to their harmful effects on the ozone layer and their high global warming potential. This has pushed the industry to develop more environmentally friendly alternatives.

Emerging Eco-friendly Refrigerants

Several new, eco-friendly refrigerants have emerged in recent years, including hydrofluoroolefins (HFOs) and natural refrigerants like CO2 and ammonia. These refrigerants offer improved environmental performance while still providing effective cooling.

Energy Consumption and Sustainability

Reducing energy consumption and improving sustainability are critical goals for the cooling industry. With energy costs rising and the need to reduce greenhouse gas emissions, there’s a strong push for more efficient and sustainable cooling technologies.

Strategies to Reduce Energy Consumption

There are various strategies that can help reduce energy consumption in cooling systems, such as optimizing component design, using advanced refrigerants, and implementing smart control systems, as we’ve discussed earlier. By focusing on these areas, we can create more energy-efficient cooling systems for the future.

Integration with Renewable Energy Sources

Another way to improve sustainability is by integrating cooling systems with renewable energy sources like solar or wind power. This can help offset some of the energy consumption and reduce the overall environmental impact of cooling systems.

Future Trends and Advancements in Vapor Compression Refrigeration

So, what does the future hold for vapor compression refrigeration cycle efficiency? Let’s take a peek at some emerging trends and advancements.

Magnetic Refrigeration and Other Alternatives

Magnetic refrigeration is an exciting new technology that uses magnetic fields instead of refrigerants to create cooling. This promising alternative could offer improved efficiency and reduced environmental impact. While it’s still in the early stages of development, it has the potential to revolutionize the cooling industry.

Innovations in Heat Exchanger and Compressor Technologies

Advancements in heat exchanger and compressor technologies are continually being developed to improve efficiency and performance. These innovations can help push the boundaries of what’s possible in vapor compression refrigeration systems.

Smart Systems and Internet of Things (IoT) Integration

As smart systems and IoT technology continue to evolve, we can expect to see even more advanced control strategies and monitoring capabilities integrated into cooling systems. This will help further optimize performance and efficiency, making our homes and appliances even cooler, smarter, and more efficient.