DIY absorption refrigerator, ever heard of it? If you’re a homeowner looking to reduce your carbon footprint and save some money, this may be the perfect project for you. In this article, we’ll explore the world of absorption refrigeration, compare it to traditional vapor-compression systems, and guide you through the process of building your very own eco-friendly fridge. So, let’s dive in, shall we?

Table of Contents

What is an Absorption Refrigerator?

Imagine a fridge that runs on heat instead of electricity. Sounds like magic, right? Well, that’s absorption refrigeration for you!

Basics of Absorption Refrigeration

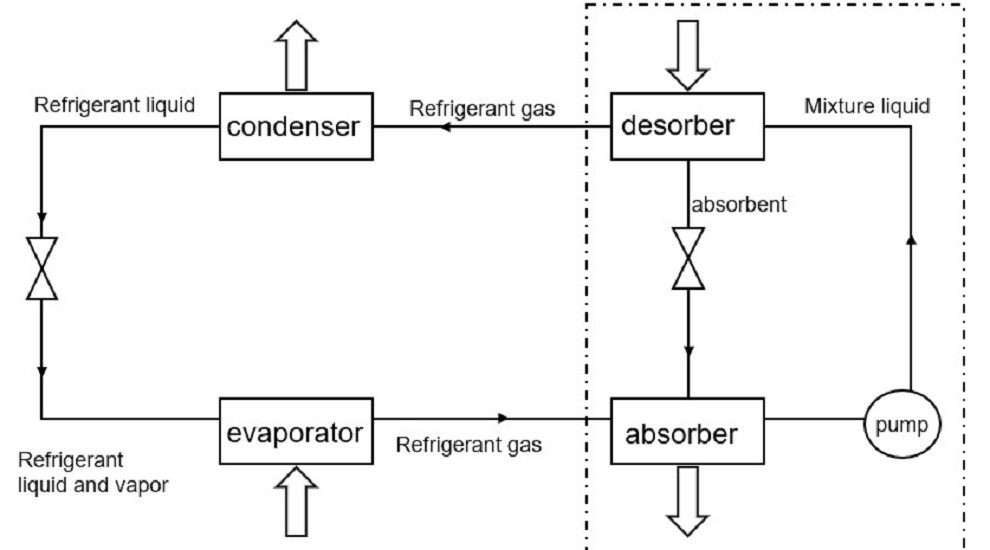

It’s a technology that’s been around since the 1800s, using heat to move a refrigerant through a cycle of evaporation and absorption, effectively cooling the inside of the fridge. Pretty cool, huh?

Advantages and Disadvantages

So, why isn’t everyone using absorption refrigerators? Well, they’re generally less efficient than traditional vapor-compression systems, but they have their perks – they’re quiet, vibration-free, and can run on alternative energy sources like solar or gas.

Comparing Absorption Chillers and Vapor-Compression Refrigerators

Key Differences

While vapor-compression systems use mechanical compressors to move refrigerant around, absorption systems rely on a heat-driven process. This means no moving parts, resulting in a whisper-quiet operation.

Energy Efficiency

When it comes to energy efficiency, vapor-compression systems usually win. However, with a well-designed DIY absorption refrigerator, you can still achieve respectable efficiency – especially if you’re using renewable energy sources.

To read more indepth articles, click here: Absorption Refrigeration: Easy Guide to Understanding It

Absorption Refrigerator DIY: Building Your Own

Gathering Materials and Tools

Required Materials

Ready to start building? You’ll need an evaporator, absorber, generator, condenser, expansion valve, refrigerant, and absorbent. We’ll explain these components in the next section.

Essential Tools

As for tools, you’ll need a pipe cutter, pipe bender, wrench, soldering iron, and leak detector. Don’t forget your safety goggles and gloves!

Safety Equipment

Speaking of safety, make sure you have a fire extinguisher and a well-ventilated workspace. Safety first, folks!

Understanding the Basic Components

Now that we’ve gathered our materials and tools, let’s get familiar with the parts of an absorption refrigerator.

Evaporator

The evaporator is where the refrigerant evaporates and absorbs heat from the fridge’s interior, keeping your food cool and fresh.

Absorber

The absorber collects the evaporated refrigerant and combines it with the absorbent, creating a solution that’s ready for the next step in the cycle.

Generator

The generator heats up the refrigerant-absorbent solution, separating them and sending the refrigerant to the condenser.

Condenser

The condenser cools the refrigerant, turning it back into a liquid, and sends it to the expansion valve.

Expansion Valve

The expansion valve controls the flow of refrigerant back into the evaporator, starting the cycle anew.

Refrigerant and Absorbent

Common refrigerants include ammonia or water, while the absorbent can be a salt like lithium bromide. Choose wisely, as different combinations have varying efficiency and safety implications.

Step-by-Step Guide on How to Make an Absorption Refrigerator

Building the Evaporator and Absorber

Start by constructing the evaporator and absorber, making sure they’re properly sealed to prevent leaks. This is where your pipe bending and soldering skills will come in handy.

Constructing the Generator and Condenser

Next, build the generator and condenser, ensuring they’re well-insulated and connected to the appropriate heat source. Don’t forget to attach a vent for the waste heat!

Assembling the Expansion Valve

Now, assemble the expansion valve and connect it to the evaporator and condenser, making sure the flow of refrigerant is properly regulated.

Connecting the Components and Adding Refrigerant

With all the components in place, connect them using pipes and fittings, ensuring a tight seal. Finally, add the refrigerant and absorbent, and voila! Your DIY absorption refrigerator is ready to go.

Testing and Fine-Tuning

Before you start celebrating, test your fridge for leaks and cooling efficiency. Fine-tune the system as needed to achieve optimal performance.

Absorption Chiller DIY: Alternative Applications

What is an Absorption Chiller?

Absorption chillers work on the same principle as absorption refrigerators, but they’re used to cool larger spaces or provide air conditioning. Intrigued? Let’s learn more.

Basics of Absorption Chiller Systems

Absorption chillers are large-scale cooling systems that use heat-driven processes to produce chilled water, which is then circulated through an HVAC system to cool a building.

Advantages and Disadvantages

Like absorption refrigerators, absorption chillers are quiet, vibration-free, and can run on alternative energy sources. However, they’re also less efficient than their vapor-compression counterparts.

DIY Absorption Chiller for Cooling Applications

Materials and Tools Needed

Building a DIY absorption chiller requires similar materials and tools to an absorption refrigerator, just on a larger scale.

Building the Absorption Chiller

Construct the evaporator, absorber, generator, condenser, and expansion valve following the same principles as building an absorption refrigerator. Scale up the components to accommodate the larger cooling capacity.

Integrating the Chiller into an HVAC System

Once you’ve built your absorption chiller, connect it to your existing HVAC system to circulate the chilled water and provide cooling throughout your home.

Troubleshooting and Maintenance

Common Issues with DIY Absorption Refrigerators

Insufficient Cooling

If your fridge isn’t cooling properly, check for leaks, blockages, or an ineffective absorption process. Adjust and repair as needed.

Leaks and Blockages

Inspect your system for leaks or blockages in the pipes and fittings. Repair or replace any damaged components to ensure optimal performance.

Ineffective Absorption Process

If your absorption process isn’t working efficiently, consider swapping out your refrigerant and absorbent for a different combination or adjusting the heat source to improve performance.

Regular Maintenance and Upkeep

Inspecting for Leaks

Periodically inspect your DIY absorption refrigerator for leaks, using a leak detector to identify any problem areas. Fix any issues promptly to keep your fridge running smoothly.

Cleaning and Flushing the System

Regularly clean and flush your system to remove any build-up or contaminants that may affect performance.

Replacing Components as Needed

Over time, some components may wear out or become less effective. Replace them as needed to ensure your absorption refrigerator continues to function efficiently.

Safety Precautions and Environmental Considerations

Safe Handling of Refrigerants and Absorbents

Toxicity and Flammability

Some refrigerants and absorbents can be toxic or flammable. Always handle these materials with care and follow proper safety guidelines.

Proper Storage and Disposal

Store and dispose of refrigerants and absorbents according to local regulations to prevent harm to the environment and human health.

Ventilation and Air Quality

Ensuring Proper Ventilation

Always work on your DIY absorption refrigerator in a well-ventilated area to prevent the buildup of harmful gases.

Monitoring Indoor Air Quality

Monitor the air quality in your home to ensure your absorption refrigerator isn’t contributing to poor indoor air conditions.

Energy Efficiency and Sustainability

Choosing Energy-Efficient Components

Select energy-efficient components for your DIY absorption refrigerator to minimize your environmental impact and save on energy costs.

Incorporating Renewable Energy Sources

Consider using renewable energy sources, such as solar or geothermal, to power your absorption refrigerator and reduce your carbon footprint.

Conclusion

Final Thoughts on DIY Absorption Refrigerators

Assessing the Feasibility of a DIY Project

Before embarking on a DIY absorption refrigerator project, consider your skills, budget, and available resources. It may be a challenging undertaking, but the environmental benefits and satisfaction of creating something yourself can be well worth it.

Understanding the Limitations and Potential of Absorption Refrigeration Systems

While absorption refrigeration systems have their limitations, such as lower efficiency compared to vapor-compression systems, they offer unique advantages like quiet operation and the ability to run on alternative energy sources. Embrace the challenge and enjoy the rewards of building your own eco-friendly cooling solution.