Evaporator efficiency: ever wondered what it’s all about and why it matters? Well, you’re in luck! In this article, we’ll dive deep into evaporator efficiency, exploring its importance, factors affecting it, and ways to improve it. So, buckle up and let’s get started!

Table of Contents

Definition of Evaporator

An evaporator is a piece of equipment that’s designed to concentrate a solution by removing water or other solvents through evaporation. They come in different shapes and sizes, depending on their application.

Types of Evaporators

There are several types of evaporators, such as falling film, rising film, and forced circulation evaporators. Each type has its pros and cons, but they all aim to achieve the same goal: efficient evaporation.

Applications of Evaporators

From food processing to wastewater treatment, evaporators play a vital role in various industries. They’re used to concentrate fruit juices, dairy products, and even pharmaceuticals. Can you imagine a world without evaporators? We certainly can’t!

Importance of Evaporator Efficiency

So, why should we care about evaporator efficiency? Well, it all boils down to two crucial factors: energy consumption and product quality.

Energy Consumption

Let’s face it, energy ain’t cheap! The more efficient an evaporator is, the less energy it’ll consume, saving you money in the long run. Plus, it’s good for the environment. Win-win, right?

Product Quality

High evaporator efficiency also means better product quality. After all, nobody wants a diluted or contaminated product, do they?

Read our other articles on evaporators in refrigeration – Evaporators in Refrigeration: Easy Guide to Understanding Your Fridge’s Unsung Hero

Factors Affecting Evaporator Efficiency

Now that we know why evaporator efficiency is essential, let’s explore the factors that affect it. Spoiler alert: it’s not just about the type of evaporator!

Heat Transfer Coefficient

The heat transfer coefficient is a measure of how well heat is transferred in an evaporator. The higher the coefficient, the better the efficiency.

Types of Heat Transfer in Evaporators

There are three main types of heat transfer in evaporators: conduction, convection, and radiation. Each has its role to play in the evaporation process, and understanding them can help you optimize your evaporator’s efficiency.

Factors Influencing Heat Transfer Coefficient

Several factors influence the heat transfer coefficient, such as the type of evaporator, fluid properties, and even fouling. Yup, it’s a complex web of variables that can make or break your evaporator’s efficiency!

Temperature Difference

Temperature difference plays a vital role in evaporator efficiency. The greater the difference between the boiling point of the solution and the cooling medium, the faster the evaporation. But, there’s more to it than meets the eye!

Boiling Point Elevation

As a solution becomes more concentrated, its boiling point rises, reducing the temperature difference and, consequently, the efficiency. It’s a tricky balance, but understanding boiling point elevation can help you optimize your evaporator’s performance.

Temperature Pinch

Temperature pinch occurs when there’s a minimal temperature difference between the heating and cooling fluids. It can limit heat transfer and, therefore, evaporator efficiency. Keeping an eye on temperature pinch can help you avoid efficiency pitfalls!

Fouling

Fouling is the unwanted buildup of deposits on heat transfer surfaces, and it’s a real efficiency killer. Let’s explore its causes and effects.

Causes of Fouling

From crystallization to biological growth, there are many causes of fouling. It’s essential to identify and address the specific cause to keep your evaporator running at peak efficiency.

Effects of Fouling on Efficiency

Fouling can reduce heat transfer, increase pressure drop, and even cause corrosion. In short, it’s bad news for your evaporator’s efficiency!

Vapor-Liquid Separation

Vapor-liquid separation is the process of separating vapor from the liquid in the evaporator. It’s a crucial step for maintaining evaporator efficiency.

Importance of Separation

Proper vapor-liquid separation helps ensure the purity of both the vapor and liquid phases, which is vital for maintaining product quality and minimizing energy consumption.

Separation Techniques

There are several separation techniques, such as cyclone separators, demisters, and mesh pads. Choosing the right technique for your application is key to optimizing evaporator efficiency.

Methods to Improve Evaporator Efficiency

Enough about the factors affecting efficiency, let’s talk solutions! Here are some proven methods to improve evaporator efficiency.

Multiple-Effect Evaporation

Multiple-effect evaporation is a technique that uses multiple evaporators connected in series to make the most of the available energy. Pretty neat, huh?

Principles of Multiple-Effect Evaporation

In multiple-effect evaporation, the vapor produced in one effect is used to heat the next effect, reducing the overall energy consumption. It’s like a chain reaction of efficiency!

Benefits and Limitations

While multiple-effect evaporation can significantly improve efficiency and reduce energy consumption, it may not be suitable for all applications due to its complexity and cost.

Vapor Recompression

Vapor recompression is another method for improving evaporator efficiency. It involves compressing the vapor produced in the evaporator to increase its temperature and then using it as a heating medium. Let’s look at the two types of vapor recompression.

Mechanical Vapor Recompression

Mechanical vapor recompression uses a compressor, such as a centrifugal or screw compressor, to raise the vapor’s temperature. It’s a popular choice for its energy efficiency and versatility.

Thermal Vapor Recompression

Thermal vapor recompression, on the other hand, uses a steam jet ejector or thermocompressor to compress the vapor. It’s a simple and reliable method but may not be as energy-efficient as its mechanical counterpart.

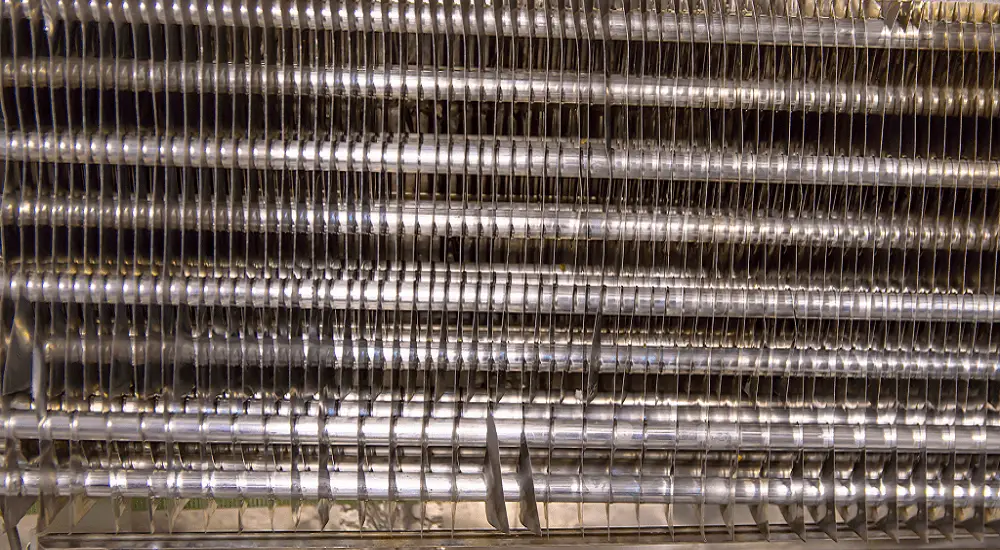

Enhanced Heat Transfer Surfaces

Using enhanced heat transfer surfaces, such as corrugated or finned tubes, can improve evaporator efficiency by increasing the heat transfer coefficient. Who knew a simple change in surface design could make such a difference?

Types of Enhanced Heat Transfer Surfaces

There are various types of enhanced heat transfer surfaces, including dimpled, micro-finned, and spiral tubes. Each type has its unique benefits and can significantly improve evaporator efficiency.

Advantages of Enhanced Surfaces

Enhanced heat transfer surfaces not only improve efficiency but also reduce fouling and pressure drop. It’s a win-win situation for your evaporator!

Optimizing Operating Parameters

Finally, optimizing operating parameters like temperature control and feed flow rate can help improve evaporator efficiency. It’s all about finding the sweet spot for your specific application!

Temperature Control

Proper temperature control is crucial for maintaining evaporator efficiency. It involves monitoring and adjusting the temperature of the heating and cooling fluids to optimize heat transfer and reduce energy consumption.

Feed Flow Rate

Controlling the feed flow rate is another essential aspect of optimizing evaporator efficiency. Ensuring a consistent and appropriate flow rate can prevent fouling and maintain product quality.

Measuring and Monitoring Evaporator Efficiency

So, how can you tell if your evaporator is running efficiently? By measuring and monitoring key performance indicators, of course!

Performance Indicators

Here are some important performance indicators to keep an eye on:

Overall Heat Transfer Coefficient

The overall heat transfer coefficient measures the effectiveness of heat transfer in the evaporator. A higher coefficient indicates better efficiency.

Steam Economy

Steam economy is the ratio of the mass of vapor produced to the mass of steam consumed. A higher steam economy means better energy efficiency.

Specific Steam Consumption

Specific steam consumption measures the amount of steam consumed per unit of product. Lower specific steam consumption indicates better evaporator efficiency.

Monitoring Techniques

Now that we know what to measure, let’s explore some monitoring techniques:

Sensors and Instrumentation

Using sensors and instrumentation, such as temperature sensors, flow meters, and pressure gauges, can help you monitor your evaporator’s performance in real-time. It’s like having a constant pulse on your evaporator’s efficiency!

Data Analysis and Performance Evaluation

Analyzing and evaluating the collected data can help you identify trends, detect potential issues, and optimize your evaporator’s performance. Knowledge is power, after all!

Conclusion

Importance of Evaporator Efficiency Optimization

Optimizing evaporator efficiency is crucial for reducing energy consumption, improving product quality, and minimizing environmental impact. So, it’s not just about saving money, it’s about being a responsible business!

Future Developments in Evaporator Technology

As technology advances, we can expect further improvements in evaporator efficiency through new materials, innovative designs, and smarter control systems. The future of evaporation looks bright, and we can’t wait to see what’s in store!