Evaporator in chiller – ever heard of it? You might not be an expert in cooling systems, but this essential component plays a massive role in keeping your favorite spaces cool and comfortable. Let’s dive into the fascinating world of chillers and evaporators!

Table of Contents

Basic Overview of Chiller Systems

Chiller systems, often found in commercial and industrial settings, are responsible for providing cooled water for air conditioning, manufacturing processes, and more. But how do they work, you ask?

Function and Role of Chillers

Chillers work by removing heat from water and transferring it to the environment. This cooled water then makes its way through various applications, absorbing more heat and returning to the chiller to be cooled again. It’s a continuous cycle!

Main Components of a Chiller System

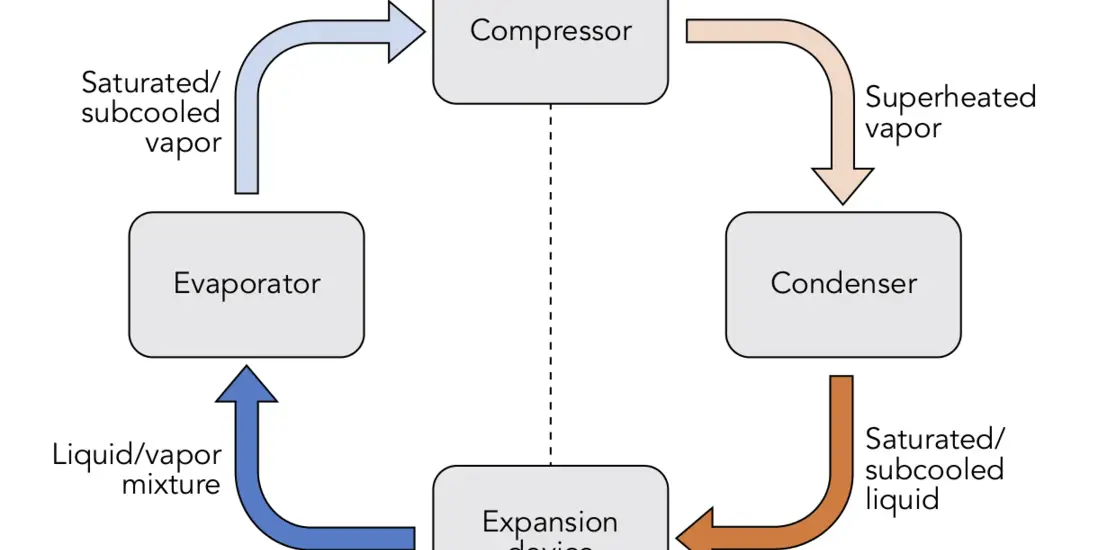

A chiller system consists of a few key components, including a compressor, a condenser, an expansion device, and our main star: the evaporator. Each of these parts plays a crucial role in the overall operation of the chiller system.

Importance of Evaporators in Chillers

Why are evaporators so important? Well, they’re the heart and soul of the cooling process. Let’s break it down further.

Heat Transfer Process

The evaporator is responsible for transferring heat from the water to the refrigerant. It’s where the magic happens, turning a hot mess into a cool, refreshing oasis.

Efficiency and Performance

Efficient heat transfer in the evaporator is key to optimal chiller performance. The better the evaporator performs, the more energy-efficient and cost-effective the system will be. Who wouldn’t want that?

Evaporator Water Chiller

Now that we’ve got the basics down, let’s dive into the world of evaporator water chillers.

How Evaporator Water Chillers Work

These chillers are specifically designed to cool water using the power of evaporation. Sounds simple, right? Let’s look closer.

Evaporator Water Chiller Process

Water flows over the evaporator tubes, where it meets the cold refrigerant. The heat is transferred from the water to the refrigerant, cooling the water and evaporating the refrigerant. This cooled water is then ready to take on more heat from its surroundings.

Applications of Evaporator Water Chillers

You’ll find evaporator water chillers hard at work in various industries, from cooling large office buildings to keeping industrial processes running smoothly. They’re true multitaskers!

Advantages of Evaporator Water Chillers

Why choose an evaporator water chiller? Here are some of the top benefits:

Energy Efficiency

Evaporator water chillers can be incredibly energy-efficient, saving both the environment and your wallet. It’s a win-win situation!

Ease of Maintenance and Operation

With fewer moving parts compared to other chiller types, evaporator water chillers are generally easier to maintain and operate. Less hassle? Yes, please!

Scalability and Flexibility

These chillers can be easily scaled to match your cooling needs, making them a versatile option for various applications. Talk about flexibility!

Chiller Evaporator Types

Not all evaporators are created equal. Let’s explore the different types and find out which one is right for you.

Shell and Tube Evaporators

Shell and tube evaporators are like the classic cars of the chiller world. They’re reliable and have been around for a long time. But what makes them tick?

Design and Structure

These evaporators consist of a shell housing numerous tubes. The refrigerant flows through the tubes, while water flows around them, transferring heat through the tube walls.

Advantages and Disadvantages

Shell and tube evaporators boast a robust design, making them suitable for various applications. However, they can be less energy-efficient than other evaporator types and require regular maintenance to prevent fouling.

Applications and Industries

From air conditioning to industrial process cooling, shell and tube evaporators can be found in a variety of settings. They’re real workhorses!

Plate Heat Exchanger Evaporators

Imagine a sleek, modern alternative to the classic shell and tube evaporator. That’s the plate heat exchanger evaporator! Let’s learn more.

Design and Structure

These evaporators feature thin, corrugated plates stacked together, forming channels for water and refrigerant to flow through. The heat transfer occurs across the plate surfaces, offering efficient cooling.

Advantages and Disadvantages

Plate heat exchanger evaporators are compact and energy-efficient, making them an attractive option. However, they can be more susceptible to fouling and may require more frequent cleaning.

Applications and Industries

You’ll find plate heat exchanger evaporators in various industries, including HVAC, food and beverage, and pharmaceuticals. They’re real multitaskers!

Direct Expansion (DX) Evaporators

Direct expansion evaporators, or DX evaporators, offer a unique twist on the classic evaporator design. Intrigued? Let’s take a closer look.

Design and Structure

DX evaporators feature a direct expansion of the refrigerant, allowing it to absorb heat from the water directly. This design can lead to improved efficiency and performance.

Advantages and Disadvantages

DX evaporators can be highly efficient and compact, but they may require more maintenance and are often limited to specific applications.

Applications and Industries

DX evaporators are commonly used in air conditioning systems, commercial refrigeration, and some industrial cooling processes. They’re perfect for specialized applications!

For more articles on evaporators in refrigeration, click here.

Evaporator of Chiller: Maintenance and Troubleshooting

Like any machine, evaporators need a little TLC to keep them running smoothly. Let’s explore the world of maintenance and troubleshooting.

Regular Maintenance Practices

Keeping your evaporator in tip-top shape doesn’t have to be a chore. Follow these regular maintenance practices to ensure smooth sailing:

Cleaning and Inspecting Evaporator Tubes

Regularly inspect and clean evaporator tubes to prevent fouling and scaling, which can reduce efficiency. A little elbow grease goes a long way!

Checking and Adjusting Refrigerant Levels

Ensure the refrigerant levels are properly maintained to keep your evaporator running at peak performance. It’s like topping off the gas in your car!

Ensuring Proper Water Treatment

Proper water treatment can help prevent fouling and scaling in your evaporator. It’s like giving your evaporator a suit of armor!

Common Evaporator Issues and Solutions

Even the best evaporators can run into issues. Let’s explore some common problems and their solutions:

Reduced Heat Transfer Efficiency

If your evaporator isn’t performing as it should, it could be due to fouling or scaling. Regular maintenance and cleaning can help prevent these issues and keep your evaporator running smoothly.

Refrigerant Leaks

Refrigerant leaks can cause a drop in evaporator performance. Regular inspections and repairs can help keep leaks in check and ensure optimal efficiency.

Fouling and Scaling

Fouling and scaling can reduce heat transfer efficiency and lead to higher energy costs. Proper water treatment and regular maintenance can help keep these issues at bay.

Evaporator in Chiller: Future Trends and Developments

As technology continues to evolve, so too does the world of evaporators. Let’s take a glimpse into the future!

Advanced Materials and Technologies

Expect to see innovations in materials and technologies that can enhance heat transfer surfaces and improve energy efficiency. The future looks bright!

Enhanced Heat Transfer Surfaces

Emerging technologies aim to increase the surface area for heat transfer, improving efficiency and performance. It’s like giving your evaporator a turbo boost!

Improved Energy Efficiency

New materials and designs can help reduce energy consumption and improve overall efficiency. It’s a win for both your wallet and the environment!

Integrating IoT and Smart Controls

Imagine a world where your evaporator can communicate with you, offering real-time diagnostics and optimization. That’s the power of IoT and smart controls!

Remote Monitoring and Diagnostics

With IoT integration, you can remotely monitor and diagnose issues with your evaporator, ensuring optimal performance and reducing downtime. It’s like having a personal assistant for your evaporator!

Optimizing Chiller Performance and Efficiency

Smart controls can help you fine-tune your chiller’s performance and efficiency, ensuring you’re getting the most out of your system. It’s like having a personal trainer for your evaporator!

Conclusion

From understanding the importance of evaporators in chiller systems to choosing the right evaporator type, you’re now well-versed in the world of evaporators! Remember, proper maintenance and troubleshooting are essential to keep your evaporator running smoothly and efficiently. With the exciting advancements on the horizon, the future of evaporator technology is looking brighter than ever.

Importance of Evaporators in Chiller Systems

Never underestimate the power of a well-functioning evaporator! These essential components play a crucial role in the efficiency and performance of your chiller system.

Choosing the Right Evaporator Type

Whether you’re drawn to the classic shell and tube design or intrigued by the sleek plate heat exchanger evaporators, selecting the right evaporator type can make all the difference in your chiller’s performance.

Ensuring Proper Maintenance and Troubleshooting

Keep your evaporator in top condition with regular maintenance, inspections, and cleaning. And when issues arise, don’t be afraid to tackle them head-on. Your evaporator will thank you!