Evaporator material is a crucial aspect of any refrigeration system. But with so many options available, how do you decide which one’s best for your needs? In this guide, we’ll take a deep dive into the world of evaporator materials, so you can make an informed decision.

Table of Contents

Definition of Evaporator Material

An evaporator material is the substance used to construct the evaporator component within a refrigeration system. But why does it matter so much?

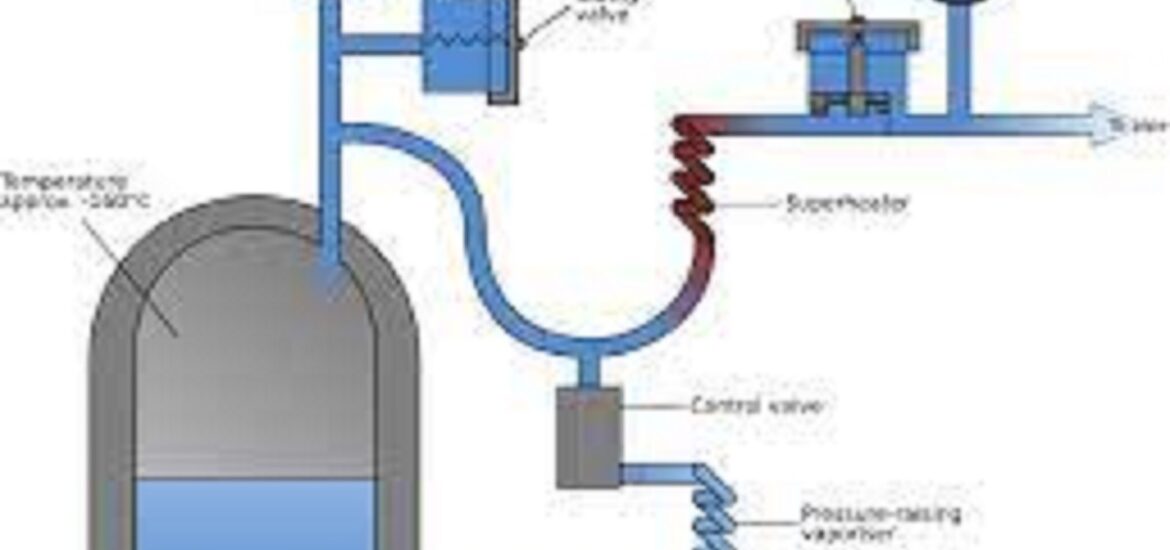

Role of Evaporator in a Refrigeration System

The evaporator’s job is to absorb heat from its surroundings, turning the refrigerant from a liquid to a gas. It’s the heart of the cooling process, so the material used plays a big part in how well the system works.

Importance of Material Selection

Choosing the right evaporator material can make all the difference in performance, efficiency, and lifespan. So, what factors should you consider?

Read more about evaporators here – – Evaporators in Refrigeration: Easy Guide to Understanding Your Fridge’s Unsung Hero

Key Factors Influencing Material Selection

When it comes to evaporator materials, there’s a lot to think about. Here are some of the most important factors:

Thermal Conductivity

The better a material’s thermal conductivity, the more efficient the heat transfer process will be. Metals like copper and aluminum are top choices for this reason. But is there a downside to these materials?

Corrosion Resistance

Corrosion can wreak havoc on your evaporator, leading to leaks and decreased performance. Some materials are more resistant to corrosion than others, like stainless steel. But is it the best choice for your evaporator?

Mechanical Strength

A material’s mechanical strength is crucial for the evaporator’s durability. A strong material will hold up under the pressure and wear of the refrigeration process. Which materials should you consider for strength?

Cost and Availability

Last but not least, cost and availability are always factors to consider. You’ll want a material that’s not only affordable but also readily available. So, which materials fit the bill?

Types of Evaporator Materials

Now that we know what to look for, let’s explore some of the most common evaporator materials and their pros and cons.

Metals

Metals are a popular choice for evaporator materials due to their thermal conductivity and strength. Let’s take a closer look at some of the most common options.

Copper

Copper is a top choice for many, but is it right for you?

Advantages of Copper

Copper boasts excellent thermal conductivity and is relatively resistant to corrosion. Plus, it’s widely available and easy to work with. Sounds like a winner, right?

Disadvantages of Copper

While copper has a lot going for it, it can be pricey. Additionally, it’s not immune to corrosion, especially in certain environments. Is there a better option?

Aluminum

Aluminum is another popular choice for evaporator materials. But how does it stack up against copper?

Advantages of Aluminum

Aluminum is lightweight, affordable, and boasts good thermal conductivity. It’s also more resistant to corrosion than copper in some environments. Could this be the perfect choice for your evaporator?

Disadvantages of Aluminum

While aluminum has many benefits, it’s not as strong as copper or stainless steel. It’s also more susceptible to galvanic corrosion when in contact with other metals. So, is there an even better option out there?

Stainless Steel

Stainless steel is known for its strength and corrosion resistance. But is it the ideal evaporator material?

Advantages of Stainless Steel

Stainless steel is incredibly strong and resistant to corrosion, making it a durable choice for evaporators. It’s also widely available, though it can be more expensive than aluminum. So, is it worth the investment?

Disadvantages of Stainless Steel

While stainless steel has many benefits, it doesn’t boast the same thermal conductivity as copper or aluminum. This means it may not be the most efficient choice for your evaporator. So, what other materials should you consider?

Non-Metals

Non-metal evaporator materials offer unique benefits and challenges. Let’s explore two popular options: polymers and composite materials.

Polymers

Polymers are versatile materials that can offer unique benefits for evaporators. But are they the right choice for your system?

Advantages of Polymers

Polymers are highly resistant to corrosion, lightweight, and affordable. They can also be tailored to meet specific performance requirements. Sounds promising, doesn’t it?

Disadvantages of Polymers

While polymers have many advantages, their thermal conductivity is generally lower than that of metals. They can also be less durable and more prone to wear. So, are composite materials a better option?

Composite Materials

Composite materials combine the best of both worlds, offering unique advantages for evaporators. But are they the right choice for your system?

Advantages of Composite Materials

Composite materials can offer excellent thermal conductivity, corrosion resistance, and mechanical strength. They can also be tailored to meet specific performance requirements. Sounds like a winning combination, right?

Disadvantages of Composite Materials

While composite materials have many benefits, they can be more expensive and challenging to manufacture than other options. So, are they worth the investment?

Material Properties and Performance

Now that we’ve explored some of the most popular evaporator materials, let’s dive deeper into the properties that impact their performance.

Thermal Conductivity

As we’ve mentioned, thermal conductivity is a key factor in evaporator performance. But what exactly is it?

Definition of Thermal Conductivity

Thermal conductivity is the ability of a material to transfer heat. A material with high thermal conductivity can move heat more efficiently, making for a more effective evaporator. So, which materials are the best performers in this category?

Impact on Evaporator Performance

The better a material’s thermal conductivity, the more efficient the heat transfer process will be. This means a more effective and energy-efficient evaporator. But how do our various materials stack up in terms of thermal conductivity?

Comparison of Thermal Conductivity in Different Materials

Copper and aluminum boast the highest thermal conductivity among our options, with copper being the top performer. Stainless steel, polymers, and composite materials generally have lower thermal conductivity, but can still offer acceptable performance depending on the application.

Corrosion Resistance

Corrosion resistance is crucial for ensuring the longevity and performance of your evaporator. So, what is corrosion, and how can it impact your system?

Definition of Corrosion

Corrosion is the process by which a material degrades due to its interaction with its environment, such as exposure to moisture, chemicals, or other materials. This can lead to leaks, decreased performance, and even system failure. So, which materials offer the best corrosion resistance?

Corrosion Mechanisms in Evaporators

There are several mechanisms by which corrosion can occur in evaporators, including galvanic corrosion, pitting, and crevice corrosion. Understanding these mechanisms can help you choose the right material for your application. So, which materials are most resistant to these types of corrosion?

Comparison of Corrosion Resistance in Different Materials

Stainless steel is highly resistant to corrosion, making it a top choice for many applications. Aluminum also offers good corrosion resistance, though it can be susceptible to galvanic corrosion. Copper has moderate corrosion resistance but may be susceptible to certain types of corrosion. Polymers and composite materials are generally highly resistant to corrosion, making them a popular choice in corrosive environments.

Mechanical Strength

Mechanical strength is important for ensuring the durability of your evaporator. But what is mechanical strength, and how does it impact evaporator performance?

Definition of Mechanical Strength

Mechanical strength refers to a material’s ability to withstand forces, such as pressure and wear, without breaking or deforming. A material with high mechanical strength will be more durable and less prone to failure. So, which materials are the strongest?

Impact on Evaporator Durability

A strong material will hold up under the pressure and wear of the refrigeration process, ensuring a longer-lasting evaporator. So, which materials should you consider for strength?

Comparison of Mechanical Strength in Different Materials

Stainless steel is the clear winner when it comes to mechanical strength, followed by copper and aluminum. Polymers and composite materials can offer varying levels of strength, depending on their composition and design.

Environmental and Economic Considerations

When choosing an evaporator material, it’s important to consider the environmental and economic implications of your decision. Let’s explore some of these factors.

Environmental Impact

The environmental impact of your chosen material can be influenced by factors such as material extraction, production, and waste disposal. So, which materials have the lowest environmental impact?

Material Extraction and Production

Metal production, particularly for copper and aluminum, can be energy-intensive and generate significant greenhouse gas emissions. Polymers and composite materials can have a lower environmental impact, depending on their composition and production methods.

Waste Disposal and Recycling

Some materials, like metals, are easier to recycle than others, such as polymers and composites, reducing their overall environmental impact. Considering the end-of-life of your evaporator and the recyclability of its materials is an important factor in making an environmentally responsible choice.

Cost and Availability

The cost and availability of evaporator materials can vary significantly, impacting your overall budget and manufacturing timelines. So, how do our various materials compare?

Material Cost Comparison

Aluminum and polymers tend to be the most affordable options, while copper and stainless steel can be more expensive. Composite materials can vary in price, depending on their composition and manufacturing complexity.

Impact of Material Availability on Evaporator Manufacturing

Material availability can influence the lead time for evaporator manufacturing, which can be critical for projects with tight timelines. Metals like copper, aluminum, and stainless steel are widely available, while the availability of specific polymers and composite materials can vary.

Cost vs Performance Trade-off

When choosing an evaporator material, it’s essential to consider the trade-off between cost and performance. While a more affordable material may be tempting, it’s important to weigh the potential savings against the potential impact on efficiency, durability, and environmental considerations.

Future Developments and Innovations

As technology advances, new materials and innovations are constantly emerging, offering exciting opportunities for improved evaporator performance and efficiency. Let’s explore some of these cutting-edge developments.

Emerging Materials

Materials science is continually evolving, leading to the development of new materials with unique properties that could revolutionize the evaporator industry. Some of these include:

Nanostructured Materials

Nanostructured materials are engineered at the nanoscale, offering unique properties such as improved thermal conductivity and strength. These materials have the potential to greatly enhance evaporator performance.

Advanced Composite Materials

New composite materials are being developed with enhanced properties, such as increased thermal conductivity, corrosion resistance, and mechanical strength. These materials could offer significant improvements over current options.

Material Coatings and Surface Treatments

Coatings and surface treatments can be applied to existing materials to enhance their performance, offering new possibilities for evaporator design.

Surface Modification Techniques

Techniques like anodizing, electroplating, and thermal spraying can be used to modify the surface properties of materials, improving their thermal conductivity, corrosion resistance, and mechanical strength.

Impact on Performance and Durability

Coatings and surface treatments can significantly improve the performance and durability of evaporator materials, potentially extending their lifespan and reducing maintenance requirements.

Design Innovations

As materials science advances, new design innovations are emerging that take advantage of these improved properties to create more efficient and effective evaporators.

Improved Heat Transfer Designs

New evaporator designs are being developed to maximize heat transfer efficiency, resulting in more effective and energy-efficient systems.

Materials for Enhanced Energy Efficiency

With the development of new materials and design innovations, the future of evaporator technology is bright, promising increased energy efficiency and improved performance for years to come.

Conclusion

Choosing the right evaporator material is a critical decision that can significantly impact the performance, efficiency, and lifespan of your refrigeration system. By considering factors such as thermal conductivity, corrosion resistance, mechanical strength, cost, availability, and environmental impact, you can make an informed decision that best meets your needs.

Summary of Evaporator Material Selection Criteria

When selecting an evaporator material, it’s essential to consider the following criteria:

- Thermal Conductivity

- Corrosion Resistance

- Mechanical Strength

- Cost and Availability

- Environmental Impact

Evaluating each of these factors in the context of your specific application will help you find the perfect material for your evaporator.

Importance of Material Research and Innovation

As technology continues to advance, it’s crucial to stay informed about the latest developments in materials science and evaporator design. By keeping up-to-date on emerging materials, coatings, and design innovations, you can ensure that your refrigeration system remains cutting-edge and operates at peak efficiency.

In conclusion, selecting the right evaporator material is a complex decision with far-reaching implications. By carefully considering the various factors and staying informed about the latest advancements in the field, you can make a choice that leads to a high-performance, efficient, and durable refrigeration system.