Evaporator size calculator, ever heard of it? Well, it’s a game-changer for anyone looking to achieve efficient cooling in various applications. But why is it so important to get the sizing just right? Let’s dive in!

Table of Contents

Importance of Proper Evaporator Sizing (Why You Need An Evaporator Size Calculator)

Like a finely tailored suit, the perfect evaporator size is essential for top-notch performance. Let’s explore the benefits of getting it just right.

Efficiency and Performance

Imagine trying to run a marathon in shoes that are too tight or too loose. It’d be a nightmare, right? Similarly, an improperly sized evaporator can cause decreased efficiency and poor performance. You wouldn’t want that, would you?

Energy Savings

Who doesn’t love saving money? A well-sized evaporator works optimally, reducing energy consumption and ultimately cutting costs. It’s a win-win!

Preventing Short Cycling

Ever dealt with a cooling system that turns on and off repeatedly? That’s short cycling, and it’s bad news. Proper sizing can prevent this pesky problem, ensuring your system runs smoothly.

Read our other detailed articles on evaporators in refrigeration – Evaporators in Refrigeration: Easy Guide to Understanding Your Fridge’s Unsung Hero

Factors Affecting Evaporator Size

So, what exactly determines the size of an evaporator? It’s a complex process involving various factors. Let’s break them down.

Load Conditions

Understanding the load conditions is crucial in evaporator sizing. It’s like knowing how many guests you’ll have at a party, so you can prepare enough food.

Cooling Load

The cooling load is the amount of heat that needs to be removed from the space. Calculating it accurately is essential for proper evaporator sizing. Miss the mark, and you could be left with a system that’s too weak or too powerful.

Latent Heat Load

This is the heat that’s absorbed or released during phase changes, like when ice melts or water evaporates. Knowing this value helps to ensure your evaporator can handle the full load.

Safety Factor

A little wiggle room is always a good idea, right? A safety factor accounts for uncertainties in calculations, so your evaporator can handle any unexpected changes in load.

Evaporator Efficiency

Efficiency is the name of the game when it comes to evaporator sizing. Let’s look at the factors that impact it.

Overall Heat Transfer Coefficient

This value represents how effectively heat is transferred through the evaporator. A higher coefficient means more efficient heat transfer, which can impact the size needed.

Fouling Factor

Over time, deposits can build up on the evaporator surface, reducing heat transfer efficiency. Accounting for this fouling factor helps to ensure your evaporator continues to perform well, even as it ages.

Refrigerant Properties

The type of refrigerant you use plays a big role in evaporator sizing. It’s like choosing the right fuel for your car to get optimal performance.

Refrigerant Type

Different refrigerants have different properties, like boiling points and heat capacities. Choosing the right one for your application is crucial for proper evaporator sizing.

Refrigerant Flow Rate

Flow rate is like the speed of your car – too slow, and you won’t get there in time; too fast, and you’ll overshoot your destination. An optimal flow rate ensures the evaporator can handle the load efficiently.

Refrigerant Temperature and Pressure

Temperature and pressure are key factors in determining the evaporator’s performance. Make sure you account for them when sizing your evaporator.

Steps to Calculate Evaporator Size

Now that we’ve covered the basics, let’s dive into the step-by-step process of calculating the perfect evaporator size for your needs.

Step 1: Determine the Cooling Load

Calculating the cooling load is like figuring out how much food to cook for a dinner party. You need to know how many people are coming and how much they’ll eat.

Cooling Load Calculation Methods

There are various methods to calculate cooling load, such as manual calculations, software tools, or even online calculators. Choose the one that suits your needs best.

Load Calculation Examples

Want to see some examples of cooling load calculations in action? Check out these resources: [insert links to example calculations here].

Step 2: Select the Evaporator Type

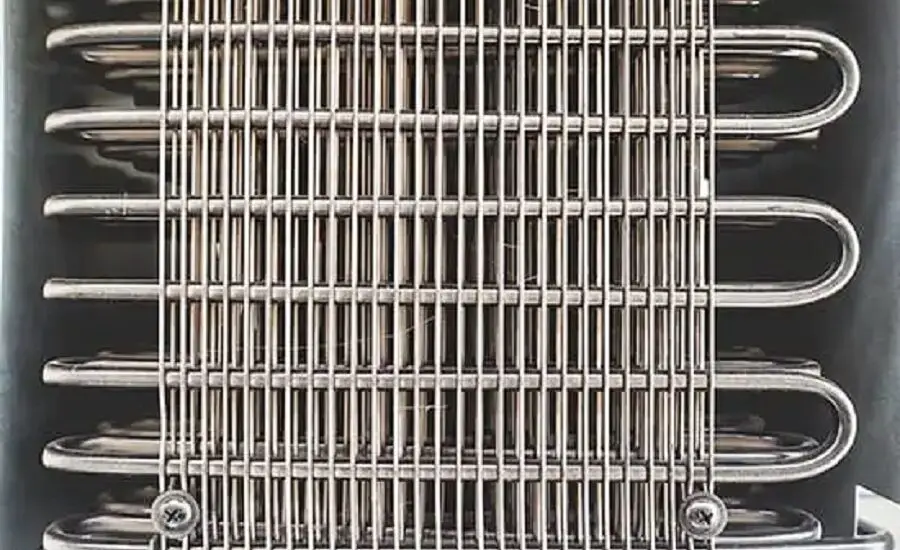

Now that you know your cooling load, it’s time to choose the right evaporator type. It’s like picking the perfect pair of shoes for your outfit.

Choosing the Right Evaporator for Your Application

Consider factors like energy efficiency, space constraints, and temperature control requirements when selecting the best evaporator for your needs. Unsure which type to choose? Consult with an expert to make the right decision.

Step 3: Calculate the Required Surface Area

With the cooling load and evaporator type in hand, it’s time to figure out the required surface area. This is like determining how big your dinner table should be to accommodate all your guests.

Surface Area Calculation Formula

Use the following formula to calculate the evaporator surface area: Surface Area = (Cooling Load × Safety Factor) / (Overall Heat Transfer Coefficient × ΔT). ΔT represents the temperature difference between the refrigerant and the air.

Calculating Surface Area Based on Efficiency

Keep in mind that the evaporator efficiency will impact the surface area needed. Make sure to account for factors like the fouling factor and overall heat transfer coefficient when making your calculations.

Step 4: Determine the Dimensions

Once you’ve got the surface area figured out, it’s time to determine the actual dimensions of your evaporator. This is like deciding the shape and size of your dinner table.

Evaporator Dimension Considerations

Take into account factors like space constraints, refrigerant flow rate, and heat transfer efficiency when determining your evaporator dimensions. Remember, the goal is to find the perfect fit for your application.

Frequently Asked Questions (FAQs)

Still have questions about evaporator sizing? We’ve got answers! Check out these frequently asked questions and their solutions.

Question 1: Can I use an evaporator that is slightly larger than calculated?

Yes, using an evaporator slightly larger than calculated can provide a safety margin and account for unforeseen changes in load. However, be cautious not to oversize it too much, as this can lead to inefficiencies and increased energy consumption.

Question 2: How do I account for future expansion in my evaporator sizing?

To account for future expansion, consider adding a safety factor to your cooling load calculations. This will ensure that your evaporator can handle increased demand as your system grows.

Question 3: Can I use a single evaporator for multiple cooling loads?

Yes, it’s possible to use a single evaporator for multiple cooling loads, as long as the combined cooling load is within the capacity of the evaporator. However, this may require additional engineering and design considerations to ensure optimal performance.