Function of a condenser in a refrigeration system — perhaps not a topic that often crosses your mind, right? But this hard-working component is the one ensuring your refrigerator keeps your ice cream frozen and your drinks cool. In simpler terms, it’s the big shot in your cooling system.

Table of Contents

The Basic Structure of a Refrigeration System

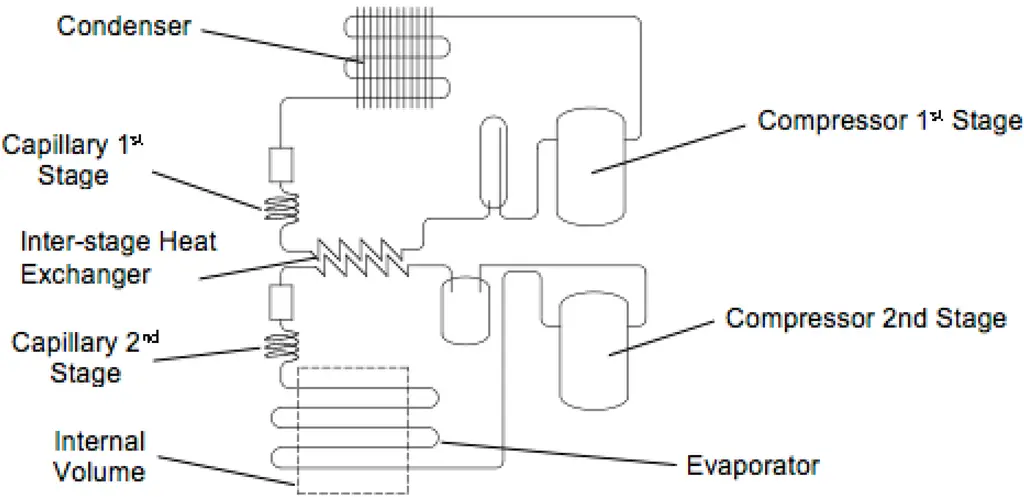

Imagine a city. Its roads, buildings, and traffic control — all crucial in its operation. Now picture a refrigeration system. It’s no different. The compressor, evaporator, expansion valve, and our star player, the condenser, each have unique roles. You’ll find the condenser rubbing shoulders with these essential parts, doing its bit to keep the system running smoothly.

Main Components of a Refrigeration System

Let’s meet the team, shall we? The compressor starts the show, pressurizing the refrigerant (our city’s fuel). This high-pressure gas then meets the condenser, where magic happens. But hold your horses, we’ll get to that! After the condenser, the expansion valve steps in, dropping the pressure. Finally, the evaporator takes over, absorbing heat and starting the cycle anew.

Role of the Condenser within the System

Ever feel like you need to cool off on a hot day? That’s the condenser’s job in a nutshell. It cools off the high-pressure gas coming from the compressor, turning it into a liquid. This process of releasing heat is vital for the refrigeration cycle. So, it’s fair to say, our condenser is a pretty cool dude.

In-Depth Look at the Function of a Condenser in a Refrigeration System

Ready to dig into what makes our cool dude tick? The condenser’s gig is a three-step dance: heat rejection, phase transition, and pressurization.

Heat Rejection in the Condenser

First, the condenser does a bit of sunbathing. The high-pressure gas, heated up from the compressor, comes in and the condenser releases this heat. It’s a bit like sweating on a hot day — it releases heat to cool down.

Phase Transition of Refrigerant

Next, the condenser works its magic, turning our hot gas into a cool liquid. It’s like condensation on a cold glass of lemonade on a hot day. The high-pressure gas releases heat (thanks to our condenser friend) and becomes a high-pressure liquid. Easy peasy, right?

Pressurization and De-pressurization of Refrigerant

Last but not least, the condenser plays a part in keeping everything under control. By handling the high-pressure gas from the compressor, and getting it ready for the low-pressure part of the cycle, the condenser is a key player in managing the system’s pressure. So, not only is it cool, it’s pretty smart too!

Check out these other related articles…

Outside Condenser Freezing Up: 4 Proven Solutions

Oversized Condenser Problems: 4 Easy Solutions

Condenser Unit Refrigeration: Your Comprehensive 411 Guide

Condenser Efficiency: Your Ultimate Guide

Condenser Subcooling: Your Comprehensive Guide

Types of Condensers in a Refrigeration System

Just as you can enjoy ice cream in a cone or a cup, there are different types of condensers: air-cooled, water-cooled, and evaporative. Each has its unique perks and preferred performances.

Air-Cooled Condensers

Picture your standard air conditioner. It uses an air-cooled condenser, which works by blowing air over the refrigerant to cool it down. It’s a popular choice because it’s simple and efficient.

Water-Cooled Condensers

Think about a car’s cooling system. It’s a perfect example of a water-cooled condenser. These systems use water to remove heat from the refrigerant. They’re often more efficient than air-cooled condensers but need a steady water supply, which isn’t always ideal.

Evaporative Condensers

Combine the best of both worlds, and you have an evaporative condenser. These systems use both water and air to cool the refrigerant, making them super-efficient. But, they’re more complex and need more maintenance. There’s always a catch, right?

Maintenance and Efficiency of a Condenser in a Refrigeration System

Just like keeping your car in tip-top shape, condenser maintenance is key to ensuring your refrigeration system runs smoothly. A well-maintained condenser is a happy, efficient condenser.

Common Issues Affecting Condenser Efficiency

Like a well-oiled machine, the condenser can run into a few hiccups. Dirt and debris can reduce efficiency, and leaks can impact the refrigeration cycle. It’s like running with a pebble in your shoe; it’s possible, but it sure isn’t comfortable or efficient!

Tips for Maintaining Condenser Efficiency

So, how do you keep your condenser happy? Regular cleaning is a good start, making sure it’s free of dirt and debris. And keep an eye out for leaks. A bit of TLC can go a long way in keeping your refrigeration system running smoothly.