Heat absorption refrigeration system technology is changing the game when it comes to sustainable cooling solutions. But what exactly is it, and how does it work? In this article, we’ll explore the ins and outs of these environmentally friendly systems, and why they might just be the future of refrigeration.

Table of Contents

Overview of heat absorption refrigeration systems

Definition and basic principles

A heat absorption refrigeration system is a cooling technology that uses heat as its primary energy source, instead of electricity. The basic principle behind these systems is the absorption of refrigerant vapor by a solution, which is then heated to release the vapor and continue the cycle. Pretty nifty, right?

Applications and advantages

These systems are perfect for a variety of applications, from industrial processes to residential air conditioning. One of the biggest perks? They can use renewable heat sources like solar energy or waste heat, making them a more sustainable choice for our planet. Plus, they’re quiet and require less maintenance than traditional systems.

Comparison with other refrigeration methods

When compared to traditional vapor compression refrigeration systems, heat absorption refrigeration systems have a lower coefficient of performance (COP). But don’t let that fool you! The use of renewable heat sources and reduced greenhouse gas emissions more than make up for it in terms of environmental benefits.

Click here for more articles like this – – Absorption Refrigeration: Easy Guide to Understanding It

Components of heat absorption refrigeration systems

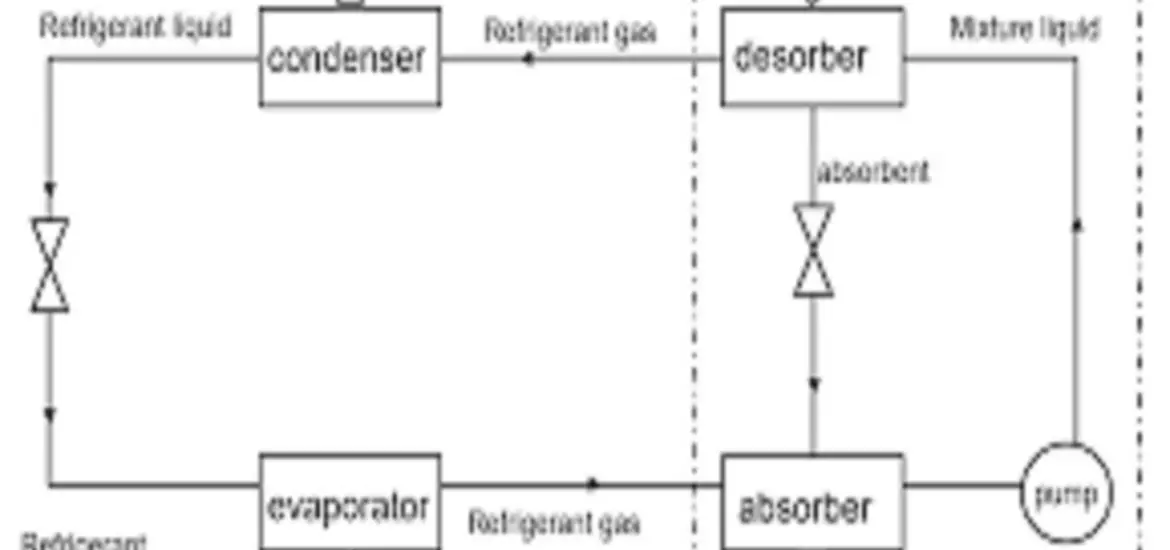

Absorber

The absorber is the heart of the system, where the refrigerant vapor is absorbed by the solution. This process creates a cooled solution that’s ready for the next step.

Generator

Here’s where the magic happens: the generator heats the cooled solution, causing the refrigerant vapor to separate and move on to the condenser.

Condenser

In the condenser, the refrigerant vapor cools down and turns back into a liquid, releasing its heat in the process. Now it’s time for the evaporator!

Evaporator

The liquid refrigerant enters the evaporator, where it absorbs heat and evaporates back into a vapor. This cools the surrounding area, creating that refreshing chill we all know and love.

Expansion valve

Between the condenser and the evaporator, the expansion valve controls the flow of the refrigerant, ensuring optimal performance.

Pump

Finally, the pump moves the cooled solution from the absorber to the generator, keeping the cycle going strong.

Working Principle of Heat Absorption Refrigeration Systems

Basic refrigeration cycle

Evaporation

As mentioned earlier, the evaporator is where the refrigerant absorbs heat and evaporates, providing that

cooling effect.

Absorption

Next, the refrigerant vapor enters the absorber, where it’s absorbed by the solution. This absorption process cools down the solution, preparing it for the generator.

Generation

When the cooled solution reaches the generator, it’s heated up to release the refrigerant vapor, which then moves to the condenser.

Condensation

In the condenser, the refrigerant vapor releases its heat and turns back into a liquid, ready to start the cycle all over again.

Heat sources

Solar energy

One of the most sustainable heat sources for heat absorption refrigeration systems is solar energy. Harnessing the power of the sun for cooling? Now that’s innovation!

Waste heat

Another eco-friendly option is using waste heat from industrial processes or other sources. This not only reduces energy consumption but also puts that waste heat to good use.

Geothermal energy

Last but not least, geothermal energy can also be used to power heat absorption refrigeration systems. Talk about tapping into the Earth’s natural resources!

Types of Heat Absorption Refrigeration Systems

Absorption refrigeration systems

Direct-fired absorption chillers

These systems use an external heat source, like natural gas, to directly heat the solution in the generator. It’s a simple and effective method for powering the refrigeration cycle.

Indirect-fired absorption chillers

Indirect-fired systems, on the other hand, use a heat exchanger to transfer heat from an external source to the solution. This offers more flexibility in terms of heat sources and system design.

Adsorption refrigeration systems

Solid-gas adsorption chillers

These systems use a solid adsorbent material, like silica gel or activated carbon, to attract and hold the refrigerant vapor. When heated, the refrigerant is released and the cycle continues.

Liquid-gas adsorption chillers

Liquid-gas adsorption systems work in a similar way, but with a liquid adsorbent instead. These systems can offer improved performance and efficiency compared to solid-gas systems.

Refrigerants and Absorbents in Heat Absorption Refrigeration Systems

Common refrigerants

Ammonia (NH3)

Ammonia is a popular refrigerant choice for heat absorption systems due to its high efficiency and low environmental impact.

Water (H2O)

Water is another common refrigerant, often used in conjunction with lithium bromide as the absorbent. This combo has a low environmental impact and is relatively safe to handle.

Hydrocarbons (HC)

Hydrocarbons, like propane and butane, can also be used as refrigerants in heat absorption systems. These options have low global warming potential, making them an eco-friendly choice.

Common absorbents

Water (H2O)

Water is not only a refrigerant but also a common absorbent in heat absorption refrigeration systems, often paired with ammonia as the refrigerant.

Lithium bromide (LiBr)

Lithium bromide is another popular absorbent, known for its high affinity for water. When paired with water as the refrigerant, it creates an efficient and environmentally friendly system.

Silica gel

Used in solid-gas adsorption systems, silica gel is an effective absorbent material that can help improve the performance of the refrigeration cycle.

Performance and Efficiency of Heat Absorption Refrigeration Systems

Coefficient of performance (COP)

Definition and calculation

The COP is a measure of a refrigeration system’s efficiency, calculated as the ratio of cooling effect to the heat input. In heat absorption systems, a higher COP means better performance and lower energy consumption.

Factors affecting COP

Several factors can impact the COP of a heat absorption refrigeration system, including the type of refrigerant and absorbent, system design, and operating conditions. By optimizing these factors, we can improve the system’s efficiency.

Efficiency improvement strategies

Heat exchanger optimization

Enhancing the performance of heat exchangers in heat absorption systems can lead to better efficiency and a higher COP. This can be achieved through improved design or the use of advanced materials.

Multi-stage systems

Implementing multi-stage systems, where the refrigeration cycle is split into multiple stages, can also help improve efficiency and reduce energy consumption.

Advanced absorption materials

Research is constantly being done to develop new and improved absorption materials that can help boost the performance of heat absorption refrigeration systems. Keep an eye on this space!

Environmental Impact and Sustainability of Heat Absorption Refrigeration Systems

Environmental benefits

Reduction in greenhouse gas emissions

By using renewable heat sources and eco-friendly refrigerants, heat absorption systems can significantly reduce greenhouse gas emissions compared to traditional refrigeration methods. That’s a win for the environment!

Utilization of renewable energy sources

Heat absorption systems can take advantage of renewable energy sources like solar and geothermal energy, helping to reduce our reliance on fossil fuels and promote sustainability.

Minimization of ozone depletion potential (ODP)

The refrigerants used in heat absorption systems generally have a low ODP, meaning they pose less risk to the ozone layer. This is another important environmental benefit of these systems.

Challenges and drawbacks

Limited efficiency compared to vapor compression systems

As mentioned earlier, heat absorption systems typically have a lower COP than vapor compression systems. However, their environmental benefits can outweigh this drawback in many cases.

Higher initial investment costs

Heat absorption refrigeration systems can have higher initial investment costs compared to traditional systems. But considering their long-term benefits, like reduced energy consumption and maintenance costs, they can be a worthwhile investment.

Availability of suitable heat sources

One challenge of implementing heat absorption systems is finding a suitable and consistent heat source. This is especially important for locations with limited access to renewable energy or waste heat.

Applications and Future Prospects of Heat Absorption Refrigeration Systems

Industrial applications

Food processing and storage

Heat absorption refrigeration systems can be an excellent choice for food processing and storage facilities, helping to maintain optimal temperatures while reducing environmental impact.

Pharmaceuticals and chemicals

These systems are also well-suited for pharmaceutical and chemical industries, where precise temperature control is crucial for product quality and safety.

Data centers and server rooms

Data centers and server rooms can greatly benefit from heat absorption refrigeration systems, as they provide efficient cooling with reduced noise and lower greenhouse gas emissions.

Commercial and residential applications

Air conditioning systems

Heat absorption systems can be used for commercial and residential air conditioning, offering a more sustainable and energy-efficient cooling solution.

Refrigeration units

From commercial refrigerators to residential fridges, heat absorption technology can help reduce energy consumption and environmental impact while keeping your food fresh and cool.

Future developments and trends

Advanced materials and technology

As research and development continue, we can expect to see more advanced materials and technologies that will improve the performance and efficiency of heat absorption refrigeration systems.

Integration with renewable energy systems

Future trends may include increased integration with renewable energy systems, allowing heat absorption refrigeration systems to further capitalize on sustainable energy sources.

Government incentives and policies

As governments worldwide recognize the environmental benefits of heat absorption systems, we may see more incentives and policies aimed at promoting their adoption and implementation.