History of the evaporator in refrigeration might sound like a dry topic, but it’s actually a fascinating tale of human ingenuity and technological advancement. Who knew that something so crucial to our modern lives had such a rich history?

Table of Contents

The Role of the Evaporator in Refrigeration

So, what’s an evaporator, and why does it matter? In a refrigeration system, the evaporator plays a critical role in absorbing heat and transforming refrigerant from a liquid to a gas. Sounds simple, right? But there’s more to it than meets the eye.

Basic Principles of Refrigeration

Refrigeration works through a process called phase change. It’s all about changing a refrigerant’s state from liquid to gas and back again, creating a cooling effect. Think of it like a dance between molecules, where heat is the dance floor and refrigerants are the partygoers.

Components of a Refrigeration System

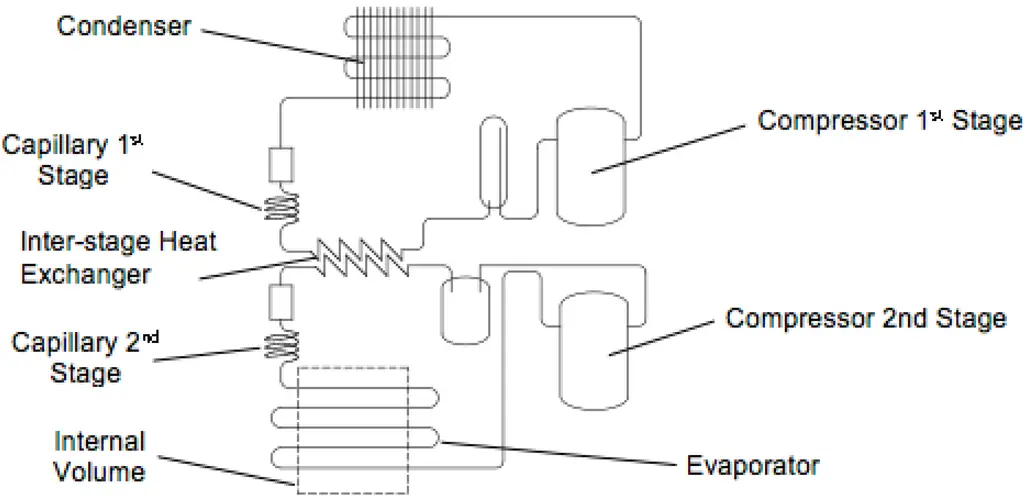

There are four main players in a refrigeration system: the compressor, condenser, expansion device, and, of course, our star, the evaporator. Each has its own unique role, but they all work together in harmony to keep things cool and chill.

Importance of the Evaporator in the Refrigeration Process

But why is the evaporator so important, you ask? Let’s dive in and find out!

Heat Exchange and Cooling

The evaporator’s main job is to absorb heat from its surroundings and transfer it to the refrigerant. This heat exchange is what ultimately cools the air, making your fridge cold and your ice cream frozen. Without the evaporator, there’d be no chill vibes in your kitchen.

Efficiency and Performance

Just like a well-trained athlete, the evaporator’s performance can make or break a refrigeration system. A good evaporator design ensures efficient heat exchange, resulting in lower energy consumption and better cooling. Talk about a win-win!

For more articles on evaporators in refrigeration, click here.

Early History of the Evaporator in Refrigeration

Early Cooling Methods

But where did it all begin? Let’s travel back in time to the early days of cooling techniques.

Ancient Civilizations and Passive Cooling Techniques

Believe it or not, ancient civilizations like the Egyptians and Romans were already using passive cooling techniques, such as evaporative cooling and ice storage. They might not have had modern evaporators, but they were definitely onto something cool.

First Ice-making Machines

Fast forward to the 19th century, and we start to see the first ice-making machines. These early contraptions used a combination of vapor compression and evaporation to make ice, paving the way for future evaporator innovations.

Emergence of Mechanical Refrigeration

Now, let’s explore the birth of mechanical refrigeration and the role of evaporators in this revolutionary process.

William Cullen’s Experiments (1748)

Scottish scientist William Cullen was a pioneer in refrigeration research. In 1748, he demonstrated the cooling effects of evaporation by boiling ethyl ether in a vacuum. Although Cullen’s experiments didn’t lead to any practical applications, they laid the groundwork for future breakthroughs in refrigeration technology.

Oliver Evans’ Vapor-Compression System (1805)

Enter Oliver Evans, an American inventor who patented the first vapor-compression refrigeration system in 1805. Evans’ design used an evaporator to absorb heat and a compressor to circulate the refrigerant. Sound familiar? That’s because this basic concept is still used in modern refrigeration systems today.

Evolution of Evaporator Design and Materials

Early Evaporator Designs

As refrigeration technology advanced, so did evaporator design. Let’s take a look at some of the early evaporator styles.

Coil and Tube Evaporators

Coil and tube evaporators, made of metal tubes arranged in coils, were among the first evaporator designs. They provided decent heat transfer, but they weren’t the most efficient or space-saving option. Nevertheless, they were a step in the right direction.

Plate Evaporators

Plate evaporators, featuring flat metal plates instead of tubes, came next. These designs offered improved heat transfer and took up less space, making them a popular choice for early refrigeration systems.

Advancements in Evaporator Materials

Just as fashion trends evolve, so too did the materials used in evaporator construction. Let’s explore some of the game-changing advancements in evaporator materials.

Introduction of Copper and Aluminum

Initially, evaporators were made from materials like iron and steel. However, the introduction of copper and aluminum revolutionized evaporator design. Why? Both metals are excellent conductors of heat, making them ideal choices for efficient heat exchange.

Role of Material Conductivity in Evaporator Efficiency

Material conductivity is a big deal when it comes to evaporator efficiency. The better a material conducts heat, the more efficient the evaporator will be. Copper and aluminum brought their A-game to the table, raising the bar for evaporator performance.

Key Innovations in Evaporator Technology

Direct Expansion (DX) Evaporators

Over time, new evaporator technologies emerged, pushing the boundaries of refrigeration efficiency. One such innovation was the direct expansion (DX) evaporator.

Development of the DX Evaporator

The DX evaporator is designed to vaporize liquid refrigerant directly, resulting in improved heat transfer and greater efficiency. This clever design helped make refrigeration systems even more effective and energy-efficient.

Advantages and Applications

DX evaporators offer several advantages, including compact size, lower refrigerant charge, and excellent cooling performance. They quickly became popular in commercial and industrial refrigeration applications, as well as in air-conditioning systems.

Flooded Evaporators

Another important innovation in evaporator technology was the development of flooded evaporators. So, what sets these evaporators apart from the rest?

Flooded Evaporator Design

Unlike DX evaporators, flooded evaporators use a pool of liquid refrigerant to fully immerse the heat exchanger tubes. This design allows for more efficient heat transfer and better temperature control, as it maintains a constant refrigerant level in the evaporator.

Benefits and Usage

Flooded evaporators offer several benefits, such as improved heat transfer, increased capacity, and reduced frost formation. These advantages make them well-suited for large-scale refrigeration applications, like industrial process cooling and cold storage facilities.

Falling Film Evaporators

Next up on our list of evaporator innovations is the falling film evaporator. What makes this design unique?

Falling Film Evaporator Concept

The falling film evaporator uses a thin film of refrigerant that flows downward over the heat exchanger tubes. This design maximizes the heat transfer surface area, resulting in increased efficiency and reduced refrigerant charge requirements.

Improved Efficiency and Industry Impact

Thanks to their superior efficiency and reduced refrigerant usage, falling film evaporators have made a significant impact on the refrigeration industry. They’re commonly used in applications like air-conditioning systems, food processing, and pharmaceutical manufacturing.

The Evaporator in Modern Refrigeration Systems

Energy Efficiency and Environmental Concerns

As our society has become more environmentally conscious, the focus on energy efficiency and eco-friendly refrigerants has grown. How have evaporators adapted to these new challenges?

Eco-friendly Refrigerants

Modern evaporators are designed to work with environmentally friendly refrigerants, such as hydrofluorocarbons (HFCs) and natural refrigerants like ammonia and carbon dioxide. This shift helps reduce the environmental impact of refrigeration systems while maintaining top-notch performance.

Energy-efficient Evaporator Designs

Today’s evaporators are more energy-efficient than ever, thanks to innovative designs and advanced materials. These improvements help reduce energy consumption and lower operating costs, making modern refrigeration systems both eco-friendly and budget-friendly.

Smart Controls and Monitoring

Another key development in modern evaporators is the integration of smart controls and monitoring. But what does that mean, exactly?

Integration of IoT Technologies

By incorporating Internet of Things (IoT) technologies, modern evaporators can be monitored and controlled remotely, providing real-time data on system performance and efficiency. This connectivity allows for better decision-making and improved system management.

Predictive Maintenance and Efficiency Optimization

Smart controls also enable predictive maintenance, helping to identify potential issues before they become costly problems. This proactive approach keeps evaporators running at peak efficiency, prolonging their lifespan and reducing downtime.

Future Prospects for the Evaporator in Refrigeration

Innovations in Evaporator Design

As we look to the future, what innovations can we expect in evaporator design? One promising development is the emergence of microchannel evaporators.

Microchannel Evaporators

Microchannel evaporators feature a network of small channels through which the refrigerant flows. This design increases the surface area for heat transfer, resulting in improved efficiency and reduced refrigerant charge. As a result, microchannel evaporators are poised to become a popular choice in next-generation refrigeration systems.

Enhanced Surface Area and Heat Transfer

The increased surface area in microchannel evaporators allows for better heat transfer and improved performance. This design innovation has the potential to revolutionize evaporator efficiency, making refrigeration systems even more energy-efficient and environmentally friendly.

Integration of Advanced Materials

Another area of future innovation lies in the integration of advanced materials. How can these new materials impact evaporator performance?

Nanotechnology and Material Innovations

Nanotechnology is opening the door to new material possibilities, such as carbon nanotubes and graphene. These materials have extraordinary thermal conductivity properties, which could be used to further enhance evaporator efficiency and performance.

Improved Thermal Conductivity and Efficiency

By incorporating advanced materials with superior thermal conductivity, future evaporator designs could achieve even greater efficiency gains. This would result in lower energy consumption and reduced environmental impact, making refrigeration systems more sustainable than ever before.

Conclusion

The Ongoing Evolution of the Evaporator in Refrigeration

From its humble beginnings to its modern-day innovations, the history of the evaporator in refrigeration is a fascinating story of human ingenuity and technological progress. As we continue to push the boundaries of efficiency and sustainability, the future looks bright for this essential component of our daily lives.

Key Takeaways

In conclusion, the evaporator has come a long way since its early days, with numerous innovations shaping its evolution. From ancient passive cooling techniques to modern, energy-efficient designs, the history of the evaporator in refrigeration is a testament to human creativity and determination.

Future Outlook

As we look forward to the future, we can expect even more exciting advancements in evaporator technology. With new materials and design concepts on the horizon, the possibilities are endless, and the evaporator’s role in refrigeration will continue to evolve and adapt to the changing needs of our world.