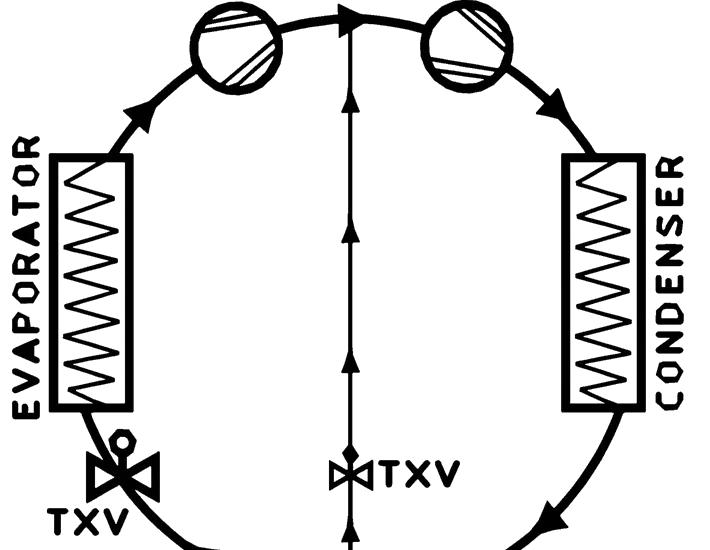

Many wonder, “how does a TXV work?” This article offers a detailed exploration of its workings in a step-by-step manner to grant you a deeper understanding of its mechanism.

Table of Contents

How Does a TXV Work?

To help you understand how a TXV works, continue reading the breakdown below:

Understanding Its Components

The TXV is a finely crafted piece of technology that contains several critical components, each having a distinct role. These components come together to regulate the refrigerant flow meticulously. Let’s examine them closely:

Temperature Sensing Bulb: This is a bulb filled with a special fluid that is highly sensitive to temperature changes. It is usually installed on the external part of the suction line, near the evaporator outlet.

Diaphragm: This is a flexible membrane that reacts to pressure changes. Positioned within the TXV, it facilitates the movement of the needle valve by responding to the pressure exerted by the fluid in the sensing bulb.

Needle Valve: This component is the main actuator that regulates the refrigerant flow. It is attached to the diaphragm, and its opening adjusts in size in response to the movements of the diaphragm, allowing more or less refrigerant to pass through.

External Equalizer: In some TXV designs, an external equalizer is used to balance the pressures and ensure the correct operation of the valve by monitoring the pressure in the evaporator.

By understanding the roles of each of these components, one can better grasp the sophisticated functioning of a TXV in regulating refrigerant flow.

Temperature Sensing

The temperature-sensing bulb stands as a vital player in the TXV operation, working continuously to sense the temperature changes occurring in the system. The fluid inside the bulb expands as it senses higher temperatures and contracts with a decrease in temperature.

This continuous reaction to temperature fluctuations triggers a series of actions: the changing pressure in the bulb impacts the diaphragm, which in turn influences the needle valve’s operation. It’s a finely tuned mechanism that ensures the system responds quickly and accurately to temperature changes, setting the stage for the crucial regulation process of the refrigerant flow.

Check out these other related articles…

How to Increase Superheat: A Step-by-step Guide

How to Lower Superheat: In 5 Easy Steps

How to Adjust Superheat on TXV: Your Easy-to-Follow Guide

How to Adjust Superheat and Subcooling: An Easy Guide

TXV HVAC: Your Comprehensive Guide

Regulating Refrigerant Flow

At this stage, the primary regulation of refrigerant flow occurs. The diaphragm, influenced by the pressure changes from the sensing bulb, drives the movements of the needle valve.

This needle valve minutely adjusts its opening size, regulating the quantity of refrigerant entering the evaporator. It is a dynamic and continuous process, responding promptly to the thermal demands of the system.

The needle valve ensures that the right amount of refrigerant is always maintained, a pivotal aspect to guarantee the efficiency and performance of the air conditioning or refrigeration system. This part of the process is essentially the heart of TXV function, where precise control meets the system’s demands.

Achieving System Balance

The TXV works tirelessly to maintain a harmonious balance within the system. Thanks to the meticulous control over the refrigerant flow facilitated by the earlier stages, a steady temperature in the evaporator is achieved and maintained.

This not only ensures that the desired cooling or heating level is reached but also guarantees that the system operates without overstraining the compressor. The TXV essentially safeguards the system against potential inefficiencies and malfunctions by continually adjusting to changing conditions, fostering a stable, efficient, and reliable operation.