Refrigerant dryer. What’s the big deal, you ask? Well, as the world gets hotter, the little things make all the difference. And this handy little appliance is the ticket to efficiency in many industries, keeping machinery humming and costs low.

Table of Contents

What is a Refrigerant Dryer?

A refrigerant dryer, in simple terms, is a device that removes moisture from the air by cooling it down with a refrigerant. But what’s so cool about that? Well, imagine a hot summer day, with air so humid, you could cut it with a knife. That’s no good for your machines, trust me.

Role of Refrigerant in a Dryer

The refrigerant is the heart and soul of a dryer. Just like how your air conditioner cools your house, the refrigerant cools the air in the dryer. This cooling condenses the moisture, which is then separated and drained away. Sounds like magic, doesn’t it?

Types of Refrigerant Dryers

Did you know there are different types of refrigerant dryers? Just like shoes, there’s a style for every purpose.

Non-Cycling Refrigerant Dryers

The non-cycling type is the old reliable of dryers. It runs continuously, keeping the pressure up and your machinery running smooth. These are known for their steady performance and reliability.

Cycling Refrigerant Dryers

The cycling type, on the other hand, is the energy saver. It cycles on and off, depending on the demand. It’s the modern solution for the environmentally conscious and the cost-conscious, as cited by Energy Star.

How does a Refrigerant Dryer work?

Let’s take a trip inside a refrigerant dryer, shall we? But don’t worry, it’s not as complex as you might think.

Key Components of a Refrigerant Dryer

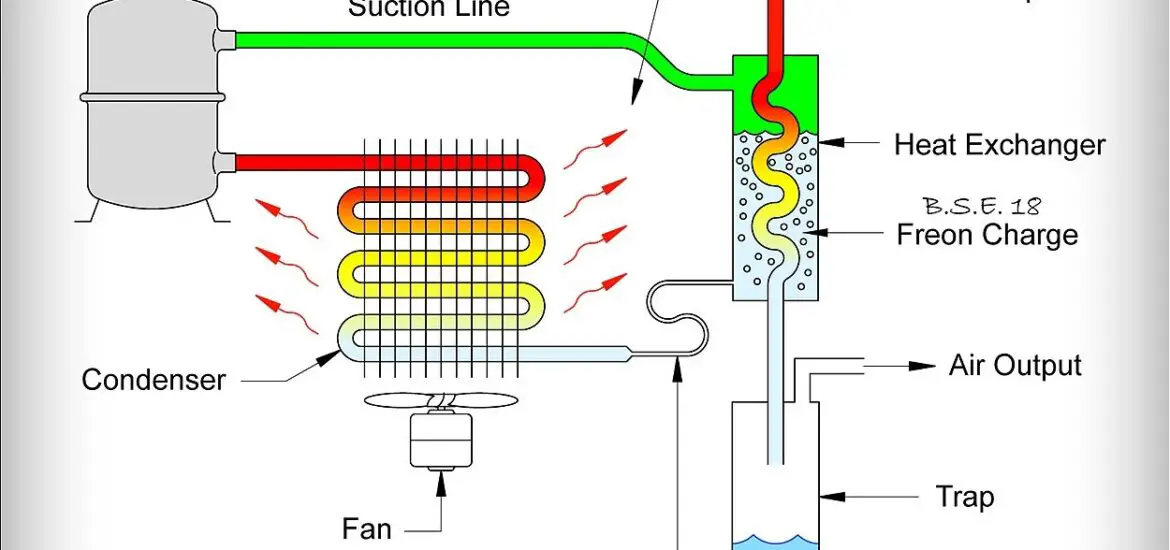

Every dryer is made up of three key parts: the compressor, the heat exchanger, and the expansion valve. These components work in harmony to keep your machinery running smooth.

Compressor

Just as your heart pumps blood around your body, the compressor pushes the refrigerant through the system. And just like a heart, it’s one of the most important parts of the system.

Heat Exchanger

The heat exchanger is the lungs of the system. It’s where the hot, moist air meets the cool refrigerant, causing the moisture to condense and be removed.

Expansion Valve

And finally, we have the expansion valve. This is where the magic really happens. It reduces the pressure of the refrigerant, allowing it to expand and cool down further.

The Drying Process

So how does all this result in dry air? Let’s go step by step. The hot, moist air enters the dryer and meets the cool refrigerant in the heat exchanger. This cools the air, causing the moisture to condense and be removed. The dry air then leaves the dryer, ready for use. Simple, isn’t it?

Read more detailed articles on refrigerants here – Articles on Refrigerants: The Ultimate Guide to Understanding Them

Benefits and Applications of Refrigerant Dryers

You might be thinking, “This all sounds great, but why should I care?” Well, refrigerant dryers are incredibly useful in a variety of industries. Let me give you a few examples.

Efficiency and Energy Savings

Firstly, refrigerant dryers are efficient. By removing moisture, they reduce the wear and tear on your machinery. This leads to fewer breakdowns and lower energy costs. Win-win, right?

Application in Various Industries

From the food and beverage industry to pharmaceuticals and manufacturing, refrigerant dryers are vital for maintaining the quality and efficiency of operations.

Manufacturing Industry

Manufacturing relies heavily on machinery, which needs dry, clean air to operate efficiently. By using a refrigerant dryer, you can reduce downtime and increase productivity. Isn’t that a dream come true?

Food and Beverage Industry

In the food and beverage industry, it’s all about quality and safety. Moisture can lead to bacteria growth, which is a big no-no. A refrigerant dryer can help keep your operations clean and safe.

Pharmaceutical Industry

In the pharmaceutical industry, purity is paramount. A refrigerant dryer ensures that the air used in production processes is free of moisture, thus preventing contamination. Can’t argue with that, can you?

Maintenance and Troubleshooting of Refrigerant Dryers

Now, let’s talk about keeping your refrigerant dryer in top shape. Don’t worry, it’s not as hard as you might think.

Regular Maintenance Practices

Just like your car, your dryer needs regular maintenance. This includes cleaning, checking for leaks, and replacing worn-out parts. A little care goes a long way, trust me.

Common Issues and Solutions

Every now and then, you might encounter a hiccup with your refrigerant dryer. But hey, don’t panic, most issues can be easily fixed if you’ve got the right know-how.

Compressor Failures

The compressor is like the heart of your dryer. But even the heart can have a bad day. If your compressor’s on the fritz, it could be due to overheating or low refrigerant levels. A simple service should get it back in tip-top shape.

Refrigerant Leaks

Refrigerant leaks can be a bit tricky. They’re like a silent assassin, causing damage without making a sound. But a sudden spike in energy bills or a loss in dryer performance could be your clue. A professional technician can help find and seal the leak, saving you a whole lot of trouble in the long run.

Electrical Issues

Electrical issues can sometimes rear their ugly heads. Flickering lights, tripped breakers, or a dryer that won’t start could signal an electrical problem. This is definitely a job for the pros, so don’t hesitate to call one in.

Moisture Issues

If you’re noticing that the air isn’t as dry as it should be, you might have a moisture issue. This could be due to a blocked drain or a malfunctioning heat exchanger. A thorough clean and check of the system should help resolve the problem.

Remember, if you’re ever in doubt or feel out of your depth, there’s no harm in asking for help. The internet is a treasure trove of information, and professional technicians are just a phone call away.

Conclusion

So there you have it, everything you need to know about refrigerant dryers. They’re efficient, they’re effective, and they’re vital in today’s industries. So next time you’re sweating in the heat, just think about your handy little refrigerant dryer, working away to keep things cool.