Got an HVAC system at home? Sure you do. But have you heard about the refrigerant metering device? This tiny part of your HVAC system plays a pretty big role, controlling the flow of refrigerant and making sure everything runs smoothly. It’s a key player in the heating, ventilation, and air conditioning game.

Table of Contents

Understanding the Function of a Refrigerant Metering Device

First things first, what does a refrigerant metering device actually do? Why is it important?

Role of the Metering Device in an HVAC System

A refrigerant metering device sits like a gatekeeper in your HVAC system. It controls how much refrigerant gets through to the evaporator coil.

Pressure and Temperature Regulation

So, what happens if the refrigerant flow isn’t controlled properly? Too much or too little, and your HVAC system won’t work as it should. The refrigerant metering device makes sure the pressure and temperature are just right. Cool, huh?

Energy Efficiency and Performance

And it’s not just about keeping you comfortable. A properly working refrigerant metering device can help your HVAC system run more efficiently. So, your energy bills stay down, and the planet stays a little bit greener. Win-win, right?

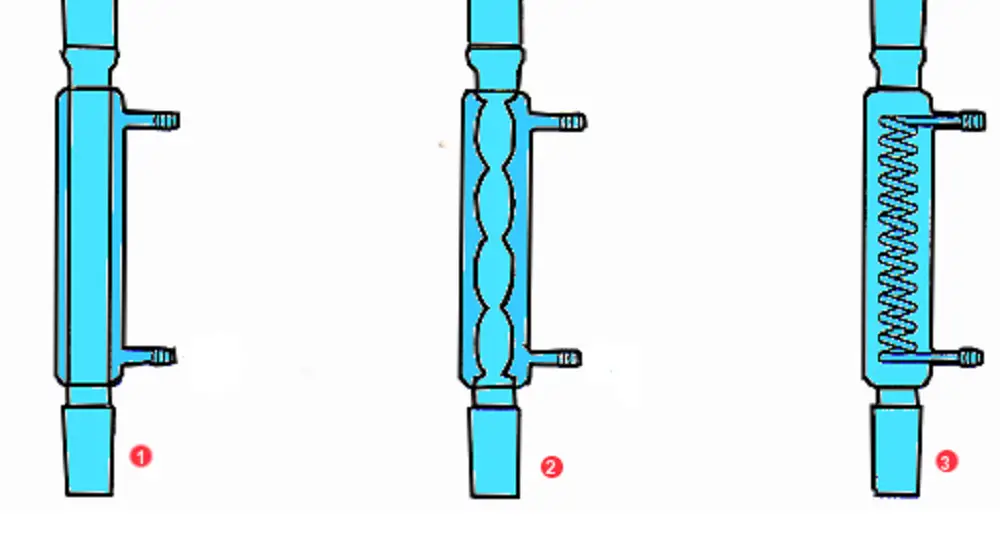

Types of Refrigerant Metering Devices

Like people, not all refrigerant metering devices are the same. There are different types to suit different systems. Let’s check them out.

Thermostatic Expansion Valve (TXV)

Meet the TXV. This little guy adjusts the flow of refrigerant based on the temperature at the evaporator coil.

Functionality of a TXV

It’s a bit like a thermostat for your HVAC system, hence the name. When it’s hot, the TXV opens up to let more refrigerant in. When it’s cool, it closes up a bit to slow the flow. Smart, isn’t it?

Benefits and Limitations of TXVs

TXVs are great for efficiency, but they can be a bit pricey. They’re also a little complex, so if something goes wrong, you might need a pro to fix it.

Fixed Orifice or Piston Metering Devices

Next up are the fixed orifice, or piston, metering devices. They’re simpler than TXVs and work a bit differently.

Functionality of Fixed Orifice Devices

Ever tried drinking a milkshake through a straw? That’s kinda how a fixed orifice device works. It’s got a small hole, or orifice, that the refrigerant flows through. The size of the hole doesn’t change, so the flow of refrigerant is constant.

Benefits and Limitations of Fixed Orifice Devices

Fixed orifice devices are simple and reliable, but they’re not quite as efficient as TXVs. So, if you’re all about that green energy, they might not be your first choice.

Capillary Tube Metering Devices

Capillary tube metering devices are another type. They’re simple, cheap, and pretty darn reliable.

Functionality of Capillary Tubes

Capillary tubes are super tiny, just like the blood vessels they’re named after. They restrict the flow of refrigerant in a similar way to fixed orifice devices, but they’re even simpler.

Benefits and Limitations of Capillary Tubes

Capillary tubes are great for small systems, but they can struggle with larger loads. So, if you’ve got a big home or office, they might not cut the mustard.

Automatic Expansion Valve (AXV)

Last but not least, we’ve got the AXV. This device adjusts the flow of refrigerant to maintain a set pressure in the evaporator.

Functionality of an AXV

Think of the AXV as a bouncer at a nightclub, letting in just the right amount of refrigerant to keep things cool. But instead of checking IDs, it’s checking pressures.

Benefits and Limitations of AXVs

AXVs can be pretty good for energy efficiency, but they’re a bit more complex than other types. So, if something goes wrong, you might need a specialist to help out.

Read our other detailed articles on refrigerants here – Articles on Refrigerants: The Ultimate Guide to Understanding Them

Selecting the Right Refrigerant Metering Device

Okay, now you know the types of refrigerant metering devices. But how do you choose the right one for your HVAC system?

Considering the HVAC System Requirements

Choosing the right refrigerant metering device starts with understanding your HVAC system’s needs. Sounds obvious, right? But, there’s more to it than you might think.

Capacity of the System

How big is your HVAC system? And I don’t just mean physical size. We’re talking about its cooling capacity. The bigger the capacity, the more refrigerant flow it’ll need.

Type of Refrigerant Used

You wouldn’t fill up a diesel truck with petrol, right? The same goes for your HVAC system. The type of refrigerant it uses will affect which metering device is right for the job.

System Design and Operating Conditions

Finally, you’ve got to consider your HVAC system’s design and operating conditions. Things like indoor and outdoor temperatures, humidity levels, and even the layout of your ductwork can make a difference.

Evaluating Cost and Efficiency

Once you’ve got the technical stuff sorted, it’s time to think about costs. And we’re not just talking about the price tag.

Initial Investment and Installation Costs

Some refrigerant metering devices cost more upfront than others. And then there’s the cost of installation to consider. But don’t forget, a higher upfront cost might mean better efficiency and lower bills in the long run.

Energy Efficiency and Operational Costs

Speaking of efficiency, this is where refrigerant metering devices can really shine. The right device can help your HVAC system use less energy, which is good news for your wallet and the environment.

Maintenance and Repair Costs

Last but not least, don’t forget about maintenance and repair costs. Some metering devices need more care and attention than others, so be sure to factor that into your decision.

Manufacturer and Product Reviews

Before you make your decision, why not see what other people have to say? Manufacturer and product reviews can give you a pretty good idea of what you’re getting into.

Reputation of the Manufacturer

Just like you wouldn’t buy a car from a dodgy dealer, you shouldn’t buy a refrigerant metering device from a manufacturer with a bad rep. Look for companies that are known for their quality and service.

Product Ratings and Reviews

And don’t forget about the product itself. What do people who’ve bought and used it have to say? The good, the bad, and the ugly – it’s all valuable information when you’re making your decision.

Maintenance and Troubleshooting of Refrigerant Metering Devices

Once you’ve got your refrigerant metering device, it’s important to keep it in tip-top shape. But how do you do that?

Regular Maintenance Practices

Like any machine, your refrigerant metering device needs regular check-ups. This helps ensure everything keeps running smoothly and efficiently.

Cleaning and Inspection

First off, keeping your metering device clean can go a long way. Regular inspections can also help you spot any potential issues before they become bigger problems. It’s a bit like taking your car in for a service, you know?

Replacement of Worn Out Parts

Just like you wouldn’t drive on worn-out tires, you shouldn’t let worn-out parts in your metering device slide. If something needs replacing, get it done sooner rather than later.

Troubleshooting Common Problems

Of course, even with the best maintenance, things can still go wrong. Knowing how to troubleshoot common problems can save you a lot of hassle (and money).

Identifying Symptoms of Faulty Metering Devices

Like a doctor diagnosing a patient, you’ve got to know what symptoms to look for. Things like inconsistent cooling, high energy bills, or unusual noises can all be signs of a faulty metering device.

Diagnosing and Fixing Issues

Once you’ve identified the symptoms, it’s time to diagnose the issue. This might be something you can do yourself, or you might need to call in a pro. Either way, it’s important to get it fixed as soon as possible.

Future of Refrigerant Metering Devices

So, what does the future hold for refrigerant metering devices? As technology advances and environmental regulations tighten, it’s an exciting time for the industry.

Impact of Evolving Refrigerant Standards

Changes in refrigerant standards are likely to have a big impact on the future of metering devices. This could mean new types of devices, or changes to existing ones.

Transition to Low-GWP Refrigerants

As the world moves towards low-global warming potential (GWP) refrigerants, metering devices will need to adapt. This could mean changes to their design, function, or even the materials used to make them.

Effect on Metering Device Design

The transition to low-GWP refrigerants might also affect the design of metering devices. For example, they might need to be more precise, or capable of handling different types of refrigerants.

Technological Advancements in Metering Devices

Of course, technology is always advancing, and the world of refrigerant metering devices is no exception. New technologies could bring more efficient, reliable, or even smarter devices.

Smart Metering Devices

Imagine a refrigerant metering device that can adjust itself based on the weather, or that you can control from your phone. Sounds futuristic, right? Well, it might not be too far off.

Advances in Efficiency and Performance

Finally, we can expect to see advances in efficiency and performance. That means even better energy savings, lower bills, and more environmentally friendly HVAC systems. Sounds good, doesn’t it?