Refrigeration by absorption isn’t your everyday cooling solution, but it’s gradually gaining traction as an eco-friendly alternative. So what’s the scoop on this intriguing technology? Keep reading to find out!

Table of Contents

What is Refrigeration by Absorption?

Absorption refrigeration is a method that uses heat to produce a cooling effect. Yep, you read that right, it uses heat to create cold!

Basic Principles of Absorption Refrigeration

At the core of this technology is a simple idea: using a refrigerant and an absorbent that work in tandem to move heat from one place to another. This dynamic duo continuously cycles through evaporation, absorption, and desorption to make the magic happen.

Comparison with other Refrigeration Methods

Compared to traditional compression-based cooling systems, absorption refrigeration has some unique benefits. It’s more eco-friendly, thanks to its use of heat sources like solar or waste heat, and it’s much quieter. But, it’s not all sunshine and rainbows; absorption systems can be less efficient and more complex.

Advantages and Disadvantages of Absorption Refrigeration Systems

Let’s weigh the pros and cons of these systems, shall we?

Energy Efficiency and Environmental Impact

One of the biggest selling points of absorption refrigeration is its ability to run on heat sources like solar energy or waste heat from industrial processes. This makes it a pretty green choice for Mother Earth.

Noise and Vibration Reduction

If you’re tired of that constant hum from your fridge, absorption refrigeration might be your saving grace. With fewer moving parts, these systems operate in near silence, making them a peaceful option for homes and businesses alike.

Limitations and Drawbacks

While absorption refrigeration has its merits, it’s not perfect. They’re typically less efficient than compression-based systems and can be more complex to install and maintain. They also require a steady heat source to function optimally, which isn’t always a guarantee.

Read our other detailed articles on absorption refrigeration – Absorption Refrigeration: Easy Guide to Understanding It

Components of an Absorption Refrigeration System

Curious about what makes an absorption refrigeration system tick? Let’s break down its key components.

Absorption Refrigeration Unit

The absorption refrigeration unit is the heart of the system, where all the major action takes place.

Function and Purpose

Its main job is to house the components that facilitate the absorption refrigeration process, such as heat exchangers, pumps, and valves. It’s where the refrigerant and absorbent interact to create that cool, refreshing air.

Different Types of Absorption Refrigeration Units

There are two primary types of absorption units: ammonia-water and lithium bromide-water. They differ in their choice of refrigerant-absorbent pairs and have varying applications, strengths, and limitations.

Refrigerant and Absorbent

These two substances play a vital role in the absorption refrigeration process. Without them, there would be no cooling effect!

Common Refrigerant-absorbent Pairs

Ammonia and water, as well as lithium bromide and water, are the most popular pairs in absorption refrigeration systems. Each combo has its own unique properties and advantages.

Criteria for Selecting Refrigerant-absorbent Pairs

When choosing a refrigerant-absorbent pair, factors like compatibility, thermal stability, and environmental impact should be taken into consideration. It’s all about finding the perfect match for your specific needs.

Heat Exchangers

Heat exchangers are a critical component of absorption refrigeration, helping to transfer heat efficiently throughout the system.

Function and Importance

These trusty devices facilitate heat transfer between the refrigerant and absorbent, ensuring that the system runs smoothly and effectively.

Types of Heat Exchangers used in Absorption Systems

There are several types of heat exchangers in absorption refrigeration systems, including shell-and-tube, plate, and spiral. The choice depends on factors like space constraints, cost, and performance requirements.

Pumps and Valves

Pumps and valves play a key role in controlling the flow of refrigerant and absorbent within the system.

Function and Role in the System

These essential components help maintain the correct pressure and flow rate, ensuring that the refrigeration process runs smoothly and efficiently.

Types and Selection Criteria

When choosing pumps and valves, it’s important to consider factors like reliability, efficiency, and compatibility with the refrigerant and absorbent in use.

Absorption Refrigeration Cycles

Now let’s delve into the different cycles of absorption refrigeration and how they work.

Single-Effect Absorption Cycle

Single-effect absorption cycles are the most basic form of absorption refrigeration.

Components and Operation

This cycle involves a single heat exchanger and an evaporator/condenser combination. It’s a relatively simple process, but it’s not as efficient as its more advanced counterparts.

Applications and Limitations

Single-effect absorption cycles are commonly used in small-scale cooling applications, such as domestic refrigerators. However, their lower efficiency and capacity make them less suitable for larger industrial applications.

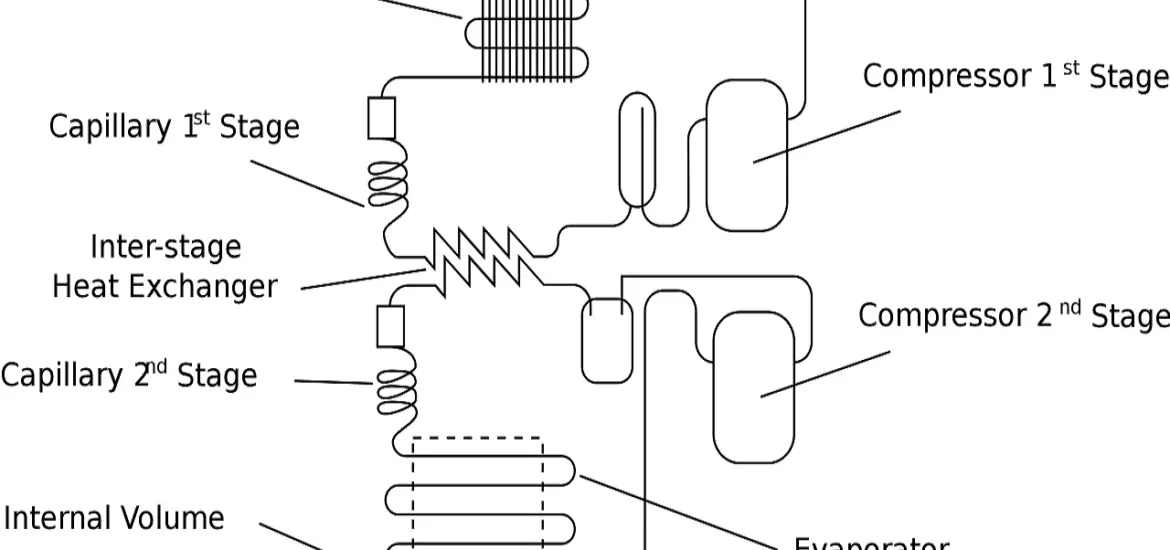

Double-Effect Absorption Cycle

Double-effect absorption cycles take things up a notch with added efficiency.

Components and Operation

This cycle features two heat exchangers, allowing for greater heat recovery and increased efficiency. By using the waste heat from the first cycle, it achieves a higher cooling capacity.

Increased Efficiency and Applications

Thanks to their improved efficiency, double-effect absorption cycles are suitable for a wider range of applications, including commercial and industrial cooling systems.

Triple-Effect Absorption Cycle

Triple-effect absorption cycles are the cream of the crop when it comes to efficiency and performance.

Components and Operation

As the name suggests, these cycles boast three heat exchangers, maximizing heat recovery and efficiency. They’re the most advanced form of absorption refrigeration technology currently available.

Higher efficiency and Potential Applications

Triple-effect absorption cycles are ideal for large-scale industrial applications where high efficiency and cooling capacity are crucial. However, their complexity and cost can make them less attractive for smaller applications.

Absorption Refrigeration Process

Let’s take a closer look at the absorption refrigeration process and how it all comes together.

Overview of the Absorption Process

The absorption process is a delicate dance of evaporation, absorption, and desorption that creates a cooling effect.

Steps in the Absorption Refrigeration Process

First, the refrigerant evaporates, absorbing heat and creating a cooling effect. The absorbent then absorbs the refrigerant vapor, and a heat source is applied to desorb the refrigerant from the absorbent. Finally, the refrigerant condenses and returns to the evaporator, starting the cycle anew.

Factors Affecting the Absorption Process

Various factors influence the efficiency of the absorption process, such as the choice of refrigerant-absorbent pair, system design, and operating conditions.

Evaporation and Condensation

Evaporation and condensation play a critical role in the absorption refrigeration process.

Role of Evaporation in Refrigeration

Evaporation is the stage where the refrigerant absorbs heat and changes from a liquid to a vapor, creating the cooling effect we all know and love.

Condensation and its Importance

Condensation is the process of the refrigerant changing back into a liquid, releasing heat in the process. This step is essential for completing the refrigeration cycle and maintaining the system’s efficiency.

Absorption and Desorption

Absorption and desorption are two vital steps in the refrigeration process, ensuring the system keeps on cooling.

Absorption of Refrigerant by Absorbent

After the refrigerant evaporates, the absorbent swoops in to absorb the vapor, effectively removing it from the system and allowing for continuous cooling.

Desorption and its Role in the Cycle

Desorption is the process of separating the refrigerant from the absorbent using heat. This step is crucial in recharging the system and maintaining the refrigeration cycle’s continuity.

Absorption Type Refrigeration Systems

Now, let’s explore the different types of absorption refrigeration systems and their applications.

Ammonia-Water Absorption System

Ammonia-water systems are a popular choice in the world of absorption refrigeration.

Properties and Advantages

Ammonia-water systems have a high affinity for each other, allowing for effective heat transfer and cooling. They’re also non-toxic and environmentally friendly.

Applications and Limitations

These systems are commonly used in commercial and industrial settings. However, their high operating pressures and potential for corrosion can be limiting factors.

Lithium Bromide-Water Absorption System

Lithium bromide-water systems are another popular option in absorption refrigeration.

Properties and Advantages

These systems have a lower operating pressure and excellent heat transfer properties. Plus, they’re less prone to corrosion compared to ammonia-water systems.

Applications and Limitations

Lithium bromide-water systems are widely used in commercial air conditioning and industrial applications. However, their sensitivity to air and moisture can be a drawback.

Other Absorption Refrigeration Systems

While ammonia-water and lithium bromide-water systems dominate the market, there are other alternatives worth considering.

Alternative refrigerant-absorbent pairs. Some alternative refrigerant-absorbent pairs include water-salt and organic solvent-organic refrigerant combinations. Researchers are continually exploring new possibilities to expand the applications and efficiency of absorption refrigeration systems.

Potential Applications and Research

These alternative systems may offer unique advantages in specific applications, such as low-temperature cooling or specialized industrial processes. Ongoing research and development may open doors to new and improved absorption refrigeration technologies.

The Role of Absorption Refrigeration in Modern Industry

From commercial air conditioning to large-scale industrial cooling, absorption refrigeration has found its place in various sectors. Its potential for using renewable energy sources and waste heat makes it an attractive option in today’s environmentally-conscious world.

Applications in Various Sectors

With growing concerns about climate change and the need for sustainable solutions, absorption refrigeration is increasingly being adopted in sectors like food processing, pharmaceuticals, and data centers, among others.

Future Developments and Potential Growth

As technology advances and new applications emerge, absorption refrigeration is poised to become an even more critical player in the cooling industry.

Technological Advancements and Future Research

With ongoing research and development, absorption refrigeration technology will continue to evolve, bringing new possibilities and improvements to the table.

Improving Efficiency and Performance

Researchers are constantly working on ways to enhance the efficiency and performance of absorption refrigeration systems, making them even more competitive with traditional cooling methods.

Development of New Refrigerant-absorbent Pairs

As new refrigerant-absorbent pairs are discovered and refined, the range of applications and capabilities of absorption refrigeration systems will continue to expand, paving the way for a cooler, greener future.

Conclusion

Now that we’ve explored the world of refrigeration by absorption, it’s clear that this technology offers a unique and eco-friendly approach to cooling.