Ever wondered how your home’s AC keeps you cool during scorching hot summers? It’s all thanks to a number of devices including one called a refrigeration heat exchanger! In this article, we’ll show you how to run your refrigeration heat exchanger calculations.

Table of Contents

Refrigeration Heat Exchanger Calculation

Design parameters and considerations

Required capacity

How much cooling do you need? The required capacity depends on factors like your home’s size, insulation, and climate. It’s essential to choose the right heat exchanger size for your specific needs.

Temperature difference

The temperature difference between the incoming and outgoing fluids affects the heat exchanger’s efficiency. A larger temperature difference typically means a more effective heat transfer, but it may also require a larger heat exchanger.

Refrigerant selection

Choosing the right refrigerant is crucial for your heat exchanger’s performance and environmental impact. Some common refrigerants are R-410A, R-22, and R-134a, each with its pros and cons.

Material compatibility

The materials used in your heat exchanger must be compatible with the refrigerant and resist corrosion. Common materials include copper, aluminum, and stainless steel.

Fouling factors

Over time, dirt and debris can build up on heat exchanger surfaces, reducing efficiency. It’s important to account for fouling factors and plan for regular maintenance to keep your system running smoothly.

Heat transfer coefficient

Convection heat transfer coefficient

This coefficient measures how efficiently heat is transferred through convection between the fluid and heat exchanger surfaces. It depends on factors like fluid properties and flow rates.

Overall heat transfer coefficient

The overall heat transfer coefficient considers both conduction and convection, giving you a comprehensive picture of your heat exchanger’s performance.

Reynolds number and Nusselt number

These two numbers help predict the heat transfer coefficient in your heat exchanger. The Reynolds number measures the flow’s turbulence, while the Nusselt number represents the ratio of convective to conductive heat transfer. Together, they help you optimize your heat exchanger’s design for maximum efficiency.

Log mean temperature difference (LMTD)

Formula and calculation

The LMTD is a crucial factor in determining the heat exchanger’s efficiency. It’s calculated using the temperature differences between the hot and cold fluids at the inlet and outlet of the heat exchanger. A higher LMTD usually means a more effective heat transfer.

Effect on heat exchanger efficiency

The LMTD directly affects the heat exchanger’s efficiency. A larger LMTD means that the heat exchanger can transfer more heat, making your cooling system more effective and energy-efficient.

Heat exchanger sizing

Area and length calculations

To determine the right size for your heat exchanger, you’ll need to calculate the required surface area for heat transfer. This depends on factors like the heat transfer coefficient, LMTD, and the desired capacity. The length of the heat exchanger is also an essential factor in its design.

Tube diameter and spacing

Choosing the right tube diameter and spacing in your heat exchanger is crucial for efficient heat transfer. Smaller tubes provide a larger surface area, but they may be more prone to fouling and harder to clean. Proper spacing between tubes ensures smooth fluid flow and efficient heat transfer.

Number of tubes or plates

The number of tubes or plates in your heat exchanger directly affects its capacity and efficiency. More tubes or plates mean more surface area for heat transfer, but they also increase the heat exchanger’s size and cost.

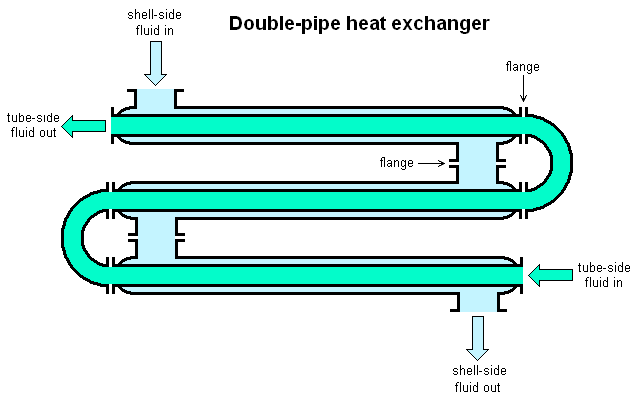

Flow arrangement

The way fluids flow through your heat exchanger can significantly impact its performance. Common flow arrangements include parallel, counterflow, and crossflow, each with its advantages and disadvantages depending on your specific needs.

Want to learn all you need to know about heat exchangers? Click here: Heat Exchangers: Easy Guide to Cooling Systems

Examples and Case Studies

Plate heat exchanger calculation

Problem statement

Let’s say you’re designing a plate heat exchanger for your home’s AC system. You’ll need to calculate the required capacity, heat transfer coefficient, LMTD, and size to ensure optimal performance.

Design parameters

You’ll need to consider factors like the required cooling capacity, temperature differences, fluid properties, and fouling factors to determine the optimal heat exchanger design.

Heat transfer coefficient calculation

Using the Reynolds and Nusselt numbers, you can calculate the convection heat transfer coefficient and the overall heat transfer coefficient for your plate heat exchanger.

LMTD calculation

By calculating the LMTD, you can determine the temperature difference driving the heat transfer in your heat exchanger, affecting its efficiency and sizing.

Heat exchanger sizing

Finally, you’ll calculate the required surface area, length, and the number of plates for your heat exchanger to meet your desired cooling capacity and efficiency.

Using the calculated values for the heat transfer coefficient, LMTD, and required capacity, you can determine the ideal size of your plate heat exchanger. This includes the surface area of each plate, the total number of plates, and the spacing between them for optimal heat transfer and fluid flow.

Shell and tube heat exchanger calculation

Problem statement

Suppose you’re tasked with designing a shell and tube heat exchanger for your home’s heat pump system. You’ll need to crunch some numbers to make sure the heat exchanger meets your system’s requirements and provides efficient performance.

Design parameters

Consider factors such as required heating or cooling capacity, temperature differences, fluid properties, and fouling factors to find the ideal shell and tube heat exchanger design for your specific needs.

Heat transfer coefficient calculation

By using the Reynolds and Nusselt numbers, you can calculate the convection heat transfer coefficient for both the shell and tube sides, as well as the overall heat transfer coefficient for your shell and tube heat exchanger.

LMTD calculation

Calculate the LMTD for your shell and tube heat exchanger to determine the temperature difference driving heat transfer. This value will have a direct impact on the heat exchanger’s efficiency and size.

Heat exchanger sizing

Based on the heat transfer coefficient, LMTD, and required capacity calculations, you can now determine the ideal shell and tube heat exchanger size. This includes the required surface area, tube length, tube diameter, and the number of tubes for optimal heat transfer and fluid flow.

Software and Tools

Commercial software

Aspen HYSYS

Aspen HYSYS is a powerful process simulation software used by engineers to design and analyze heat exchangers and other process equipment. It can help you optimize your heat exchanger design for maximum efficiency and cost-effectiveness.

Engineering Equation Solver (EES)

EES is a versatile software tool that can solve complex engineering equations and assist in heat exchanger calculations. It’s a great tool for both professionals and homeowners looking to design efficient cooling systems.

ChemCad

ChemCad is another process simulation software that can help you design and analyze heat exchangers, along with various other chemical process equipment. It offers a user-friendly interface and a comprehensive set of tools for heat exchanger calculations.

Open-source software

OpenModelica

OpenModelica is an open-source modeling and simulation environment that can be used to design and analyze heat exchangers. With its flexible and powerful capabilities, OpenModelica is an excellent tool for those looking for a cost-effective solution.

CoolProp

CoolProp is an open-source thermophysical property library that provides accurate data on various refrigerants and fluids. It’s a valuable resource for homeowners and engineers working on heat exchanger calculations and refrigeration systems.

Spreadsheet-based calculations

Microsoft Excel

Microsoft Excel is a popular spreadsheet software that can be used for heat exchanger calculations. With its built-in functions and customizable features, Excel is a versatile tool for homeowners and engineers to perform simple to complex heat exchanger analyses.

Google Sheets

Google Sheets is a free, web-based spreadsheet application that offers similar capabilities to Microsoft Excel. It’s a great option for those looking to perform heat exchanger calculations without the need for expensive software or installation.

Conclusion

Importance of accurate heat exchanger calculations

Accurate heat exchanger calculations are essential for designing efficient and cost-effective cooling systems for your home. Proper calculations ensure optimal performance, minimize energy waste, and contribute to a comfortable living environment.

Common challenges and limitations

Designing heat exchangers can be challenging due to the complex interactions between various factors, such as fluid properties, heat transfer coefficients, and temperature differences. Additionally, real-world limitations, such as fouling and manufacturing tolerances, can affect a heat exchanger’s performance.

Future advancements in heat exchanger design

As technology advances, heat exchanger designs are expected to become more efficient and adaptable to various applications. Innovations in materials, manufacturing techniques, and software tools will continue to drive improvements in heat exchanger performance and sustainability.