Subcooled boiling – what’s that all about? It’s a fascinating phenomenon that has a big impact on the world around us, and as a homeowner, you might be surprised by its relevance to your everyday life. So grab a cup of tea, sit back, and let’s dive into this intriguing topic.

Table of Contents

Definition of Subcooled Boiling

Boiling and Vaporization

Boiling is when a liquid turns into a vapor as it heats up. Think of water bubbling away on the stove. Vaporization is the process that causes boiling, turning a liquid into a gas. Simple, right?

Subcooled Liquid

Now imagine a liquid that’s cooler than its normal boiling point. That’s what we call a subcooled liquid. Subcooled boiling is when this cool liquid starts to boil. Pretty cool, huh?

Importance of Subcooled Boiling

Industrial Applications

Subcooled boiling plays a big role in various industries. From power plants to electronics manufacturing, this nifty process helps keep things running smoothly and efficiently.

Thermal Management

Keeping things cool is essential in many applications, and subcooled boiling is a star player in the game of thermal management. It helps to prevent overheating and maintain optimal performance in various systems.

Fundamentals of Subcooled Boiling

Thermodynamic Properties

Saturation Temperature and Pressure

Every liquid has a specific temperature and pressure at which it boils, called saturation temperature and pressure. When a liquid’s temperature and pressure reach these points, it’s ready to boil.

Enthalpy of Vaporization

This is the amount of energy needed to turn a liquid into a vapor. The more energy needed, the harder it is to make that liquid boil.

Latent Heat

Latent heat is the energy absorbed or released during phase changes, like when a liquid turns into a gas. It’s a key player in the boiling process.

Boiling Regimes

Nucleate Boiling

This is the stage of boiling where tiny bubbles form on a heated surface. It’s like watching champagne bubbles rise to the top of your glass.

Transition Boiling

As the heat increases, we move into transition boiling. This is when the bubbles get bigger and the liquid starts to vaporize more rapidly.

Film Boiling

When the liquid is so hot that a layer of vapor forms on the surface, we’ve hit film boiling. This is when things get steamy!

Heat Transfer Mechanisms

Conduction

Conduction is the transfer of heat through a solid material. It’s like touching a hot pot handle and feeling the heat travel through the metal.

Convection

Convection is the transfer of heat through the movement of fluids, like air or water. Picture a hot air balloon rising as the air inside heats up.

Radiation

Radiation is the transfer of heat through electromagnetic waves. Think of the warmth you feel when you stand in the sun.

Phenomena of Subcooled Boiling

Bubble Formation

Nucleation Sites

Bubbles form at nucleation sites, which are tiny spots on a heated surface where the liquid can vaporize. It’s like a tiny launchpad for bubbles!

Bubble Growth Dynamics

Once a bubble forms, it starts to grow. As the bubble gets bigger, the pressure inside decreases, causing more liquid to vaporize and join the party.

Bubble Departure and Coalescence

Bubbles eventually leave the surface and float upwards, merging with other bubbles along the way. This process is called bubble departure and coalescence. It’s like a bubble family reunion!

Forced Convection Subcooled Boiling

Flow Boiling

Flow boiling is a type of subcooled boiling that occurs when a fluid is forced to flow over a heated surface. This can help enhance heat transfer and improve cooling performance.

Critical Heat Flux

Critical heat flux is the maximum heat transfer rate that can be achieved before the boiling surface becomes covered with a layer of vapor, hindering further heat transfer. It’s like reaching the boiling point of no return!

Heat Transfer Coefficient

The heat transfer coefficient is a measure of how effectively heat is transferred between a surface and a fluid. A higher heat transfer coefficient means better cooling efficiency.

Pool Subcooled Boiling

Effects of Geometry and Surface Conditions

In pool subcooled boiling, the shape of the container and the surface conditions play a significant role in the boiling process. Things like surface roughness and the presence of contaminants can affect bubble formation and heat transfer.

Heat Transfer Coefficient Correlations

Researchers have developed correlations to predict the heat transfer coefficient in pool subcooled boiling, based on factors like fluid properties, geometry, and surface conditions. These correlations help engineers design more efficient cooling systems.

Heat Flux Partitioning

Heat flux partitioning is a way to analyze how heat is transferred during subcooled boiling. It breaks down the heat transfer into components like conduction, convection, and radiation to better understand the overall process.

Modeling and Simulation of Subcooled Boiling

Analytical and Empirical Models

Homogeneous Model

The homogeneous model assumes that the liquid and vapor phases are well-mixed, treating them as a single fluid. It’s a simplified approach that can help predict subcooled boiling behavior in certain situations.

Slip Model

The slip model takes into account the differences in velocity between the liquid and vapor phases. This more detailed model can provide better predictions for subcooled boiling behavior, especially in flow boiling scenarios.

Chen Correlation

The Chen Correlation is a popular empirical model used to predict the heat transfer coefficient in subcooled boiling. It takes into account factors like fluid properties, flow rate, and heat flux to provide accurate predictions.

Computational Fluid Dynamics (CFD)

Multiphase Flow Modeling

CFD can be used to model the complex interactions between the liquid and vapor phases during subcooled boiling. Multiphase flow modeling techniques help simulate the behavior of both phases, providing valuable insights into the boiling process.

Turbulence Modeling

Turbulence models are used in CFD to account for the chaotic, swirling motion of fluids during subcooled boiling. These models help capture the effects of turbulence on heat transfer and bubble dynamics.

Wall Boiling Models

Wall boiling models in CFD simulations focus on the interactions between the boiling surface and the fluid. These models help predict bubble nucleation, growth, and departure, which are crucial for understanding subcooled boiling behavior.

Model Validation and Uncertainty Quantification

Experimental Techniques

To validate subcooled boiling models, researchers use experimental techniques like high-speed imaging, temperature measurements, and pressure sensors. These tools help ensure that the models accurately represent real-world behavior.

Uncertainty Analysis

Uncertainty analysis is a critical step in the modeling process. It helps quantify the uncertainty in model predictions, allowing researchers to assess the reliability of their results and identify areas for improvement.

Model Improvement

By comparing model predictions with experimental data and identifying sources of uncertainty, researchers can refine their models to better capture the complex behavior of subcooled boiling, leading to more accurate predictions and better-designed cooling systems.

Practical Applications of Subcooled Boiling

Nuclear Power Plants

Reactor Coolant Systems

Subcooled boiling is a critical process in nuclear power plants, where it helps remove heat from reactor cores. Maintaining proper coolant flow and heat transfer rates is essential for safe and efficient operation.

Fuel Rod Cooling

In nuclear reactors, fuel rods generate heat that must be removed to prevent overheating. Subcooled boiling helps keep these rods cool and prevent potential accidents.

Safety Considerations

Understanding subcooled boiling behavior is vital for ensuring the safety of nuclear power plants. Accurate models and simulations can help engineers design robust cooling systems that minimize the risk of accidents.

Refrigeration and Air Conditioning

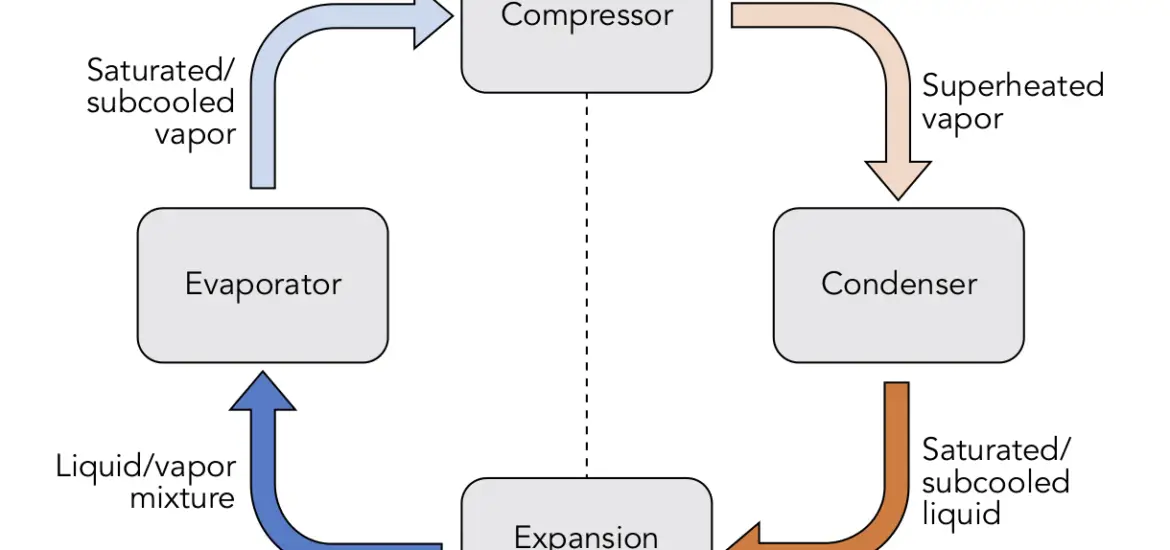

Evaporators

Subcooled boiling plays a key role in the evaporators of refrigeration and air conditioning systems. As the refrigerant boils, it absorbs heat from its surroundings, providing cooling for your home or favorite ice cream treat.

Two-phase Heat Exchangers

Two-phase heat exchangers are essential components in many cooling systems. They use subcooled boiling to transfer heat between different fluids, helping to keep things cool and efficient.

Energy Efficiency

Subcooled boiling can help improve the energy efficiency of refrigeration and air conditioning systems. By optimizing heat transfer and reducing the amount of energy required for cooling, we can save both money and the environment.

Electronics Cooling

Microchannel Coolers

Microchannel coolers are cutting-edge devices that use subcooled boiling to cool high-performance electronics. These tiny coolers can effectively dissipate heat, keeping your gadgets running smoothly.

Jet Impingement Cooling

Jet impingement cooling is another advanced technique that relies on subcooled boiling. High-velocity liquid jets are directed at a heated surface, promoting rapid boiling and efficient heat transfer.

Thermal Management Solutions

Subcooled boiling is a key technology for developing innovative thermal management solutions in electronics. As our devices become more powerful and compact, harnessing the power of subcooled boiling will be essential for keeping them cool and functional.

Future Research Directions and Challenges

Advanced Measurement Techniques

High-speed Imaging

High-speed imaging allows researchers to capture detailed visualizations of subcooled boiling processes. These insights can help improve our understanding of bubble dynamics and heat transfer mechanisms.

Laser-based Methods

Laser-based techniques, such as Particle Image Velocimetry (PIV), can provide valuable data on fluid velocities and temperatures during subcooled boiling. This information can help refine models and optimize cooling systems.

Interfacial Tracking Techniques

Interfacial tracking techniques allow researchers to study the interactions between liquid and vapor phases during subcooled boiling. These methods can provide crucial insights into bubble growth, departure, and coalescence.

Enhanced Subcooled Boiling Surfaces

Surface Modification

By modifying the surface characteristics of a boiling surface, researchers can enhance subcooled boiling performance. Techniques like micro-structuring or coating can improve bubble nucleation and heat transfer.

Nano/microstructured Surfaces

Nano and microstructured surfaces are promising avenues for enhancing subcooled boiling performance. These tiny structures can provide more nucleation sites and promote efficient heat transfer.

Phase-change Materials

Phase-change materials can store and release large amounts of heat during phase transitions, making them useful for subcooled boiling applications. They have the potential to improve cooling performance and energy efficiency in various systems.

Sustainable and Energy-efficient Systems

Waste Heat Recovery

Subcooled boiling can be used to recover waste heat from industrial processes and other sources. By harnessing this heat, we can improve the overall efficiency of our energy systems and reduce our environmental impact.

Thermal Energy Storage

Thermal energy storage systems can use subcooled boiling to store and release heat on-demand. This technology has the potential to revolutionize the way we heat and cool our homes, reducing energy consumption and greenhouse gas emissions.

Advanced Cooling Technologies

As our world becomes more reliant on advanced technologies, the need for efficient and sustainable cooling systems will only grow. Subcooled boiling research will play a crucial role in developing the next generation of cooling technologies that can meet these challenges head-on.