Subcooling in vapour compression cycle, ever heard of it? If you’re a homeowner, this little-known concept could save you big bucks and boost your home’s cooling system. Intrigued? Let’s dive in!

Table of Contents

Definition of Subcooling

So, what exactly is subcooling? In layman’s terms, it’s when a liquid (in this case, refrigerant) is cooled below its normal condensation point. And why should you care? Well, it plays a crucial role in your home’s vapour compression cycle – the process behind your air conditioner or fridge.

Vapour Compression Cycle Overview

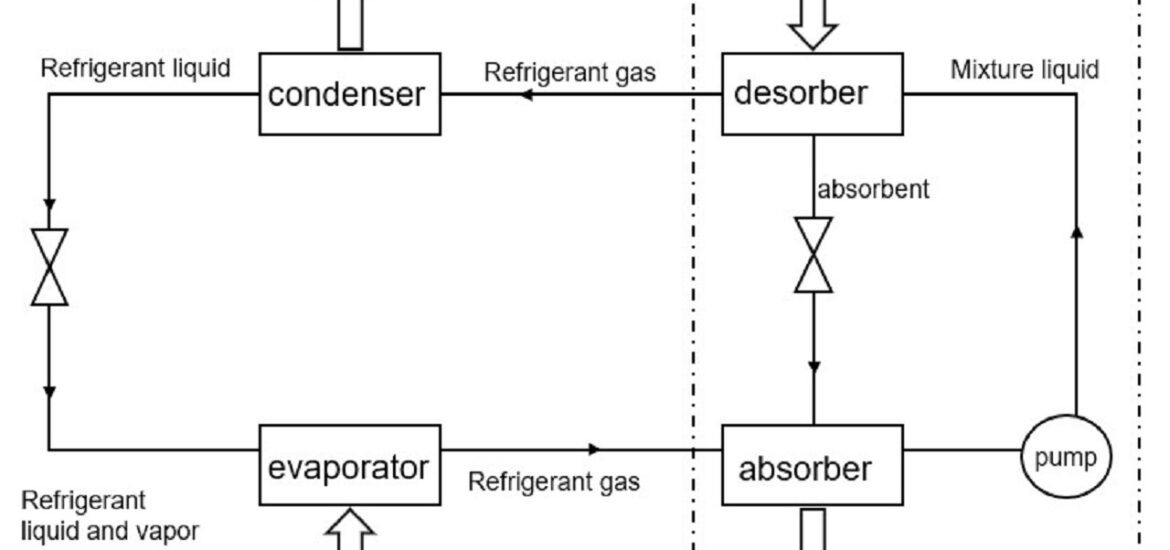

Think of the vapour compression cycle like a fancy dance with four main steps: evaporation, compression, condensation, and expansion. Subcooling struts its stuff in the condensation phase, making the entire system work more efficiently. Sounds cool, right?

The Subcooling Process

Description of the Subcooling Process

Imagine the refrigerant in your cooling system as a tightrope walker. It has to balance between being a gas (evaporation) and a liquid (condensation). Subcooling is that crucial moment when the refrigerant turns fully liquid, ready to release heat and cool your home. It’s a game-changer!

Liquid Line Subcooling

Liquid line subcooling happens when the refrigerant travels through a tube from the condenser to the evaporator. The more subcooling, the more cooling capacity you get. It’s like turning the air conditioner up to 11!

Evaporator Subcooling

Evaporator subcooling is similar, but it takes place in the evaporator coil. This extra boost of subcooling makes the refrigerant even more efficient at absorbing heat. It’s like having a turbocharger for your cooling system!

Factors Affecting the Degree of Subcooling

What makes one cooling system more subcool-tastic than another? Three main factors: ambient temperature, refrigerant properties, and system design. Consider these like ingredients in a recipe, with the perfect balance giving you the ultimate subcooling mix.

Benefits of Subcooling in Vapour Compression Cycle

Increased System Efficiency

Who doesn’t want a more efficient cooling system? Subcooling reduces the work your compressor has to do, which means a better coefficient of performance (COP) and lower energy bills. Cha-ching!

Enhanced Cooling Capacity

More subcooling equals more refrigerant flowing through your system, which means better heat transfer. Picture it like having a bigger sponge to soak up heat – it just works better!

Reduced Flash Gas Formation

Flash gas? It’s not as cool as it sounds. In fact, it can be a real buzzkill for your cooling system. Luckily, subcooling reduces the risk of flash gas formation, keeping your system humming along smoothly.

Methods for Achieving Subcooling in Vapour Compression Cycle

Mechanical Subcooling

Ready to amp up your subcooling? Mechanical subcooling is one way to do it. It involves using special devices like plate heat exchangers, shell and tube heat exchangers, or coaxial heat exchangers. It’s like outfitting your cooling system with high-performance gear!

Passive Subcooling

Passive subcooling is a more laid-back approach that doesn’t require extra equipment. Methods like liquid-suction heat exchangers or ambient air cooling can help achieve subcooling. Think of it as giving your cooling system a gentle nudge in the right direction.

Active Subcooling

Active subcooling is like having a personal trainer for your cooling system. It uses techniques like refrigerant injection or integrated subcooling systems to push the system to its full potential. Get ready to flex those subcooling muscles!

Challenges and Considerations in Implementing Subcooling

System Design and Compatibility

Before diving headfirst into subcooling, consider whether it’s a good fit for your current system. You’ll need to factor in design considerations and compatibility with existing equipment. After all, you wouldn’t want to put a square peg in a round hole!

Cost and Complexity

While subcooling can save you money in the long run, it might require a higher initial investment and additional maintenance. Make sure to weigh the pros and cons to find the best solution for your budget and needs.

Environmental and Safety Considerations

Being eco-conscious and safety-minded is always important. Consider the impact on refrigerant charge and global warming potential (GWP) when implementing subcooling. And always ensure the safe operation and handling of refrigerants. Mother Earth will thank you!

Conclusion

In conclusion, subcooling in vapour compression cycle is a cool secret every homeowner should know. With its potential to increase efficiency, enhance cooling capacity, and reduce flash gas formation, it’s a game-changer for home cooling systems. So, are you ready to take the plunge into the world of subcooling? Your home, your wallet, and the planet will all be better off for it!