Tube in tube heat exchanger refrigeration is the unsung hero of modern living, working tirelessly behind the scenes to keep our food fresh, our homes comfortable, and our industries running smoothly. In this article, we’ll explore the fascinating world of tube-in-tube heat exchangers and their essential role in refrigeration systems. So, buckle up and get ready to discover the cool science that makes our daily lives possible!

Table of Contents

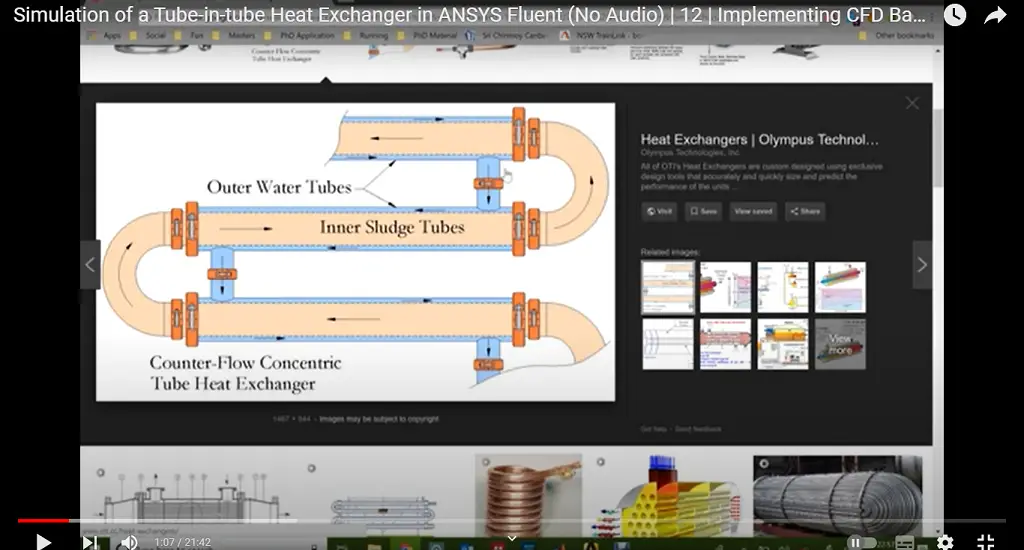

Definition of Tube-in-Tube Heat Exchanger

Simply put, a tube-in-tube heat exchanger is a device that transfers heat between two fluids without them mixing. Neat, right?

Basic components and design

The key components are two concentric tubes. The inner tube carries one fluid, while the outer tube carries the other. Heat gets exchanged between the fluids as they flow through the tubes.

Applications in various industries

These nifty gadgets are used in industries like food and beverage, HVAC, and even oil and gas refining. They’re incredibly versatile!

Importance of Heat Exchangers in Refrigeration Systems

Heat exchangers play a massive role in refrigeration systems, and here’s why:

Energy efficiency and heat recovery

They help recover waste heat and reduce energy consumption, which is great for both the environment and your wallet.

Maintaining desired temperature levels

Heat exchangers are vital for achieving and maintaining the perfect temperature in your fridge or other cooling systems. So, your ice cream stays frozen and your veggies stay crisp!

Types of Tube-in-Tube Heat Exchangers

There are two main types of tube-in-tube heat exchangers: coaxial and double pipe. Let’s get to know them better.

Coaxial Heat Exchangers

Design and construction

Coaxial heat exchangers have a single inner tube that’s surrounded by an outer tube. The fluids flow in opposite directions, resulting in efficient heat transfer.

Applications and benefits

These heat exchangers are commonly used in small-scale refrigeration systems, like residential air conditioners. They’re compact, efficient, and relatively inexpensive. Score!

Double Pipe Heat Exchangers

Design and construction

Double pipe heat exchangers have two separate pipes, one inside the other, with a gap between them. The fluids flow in the same direction, parallel to each other.

Applications and benefits

They’re used in larger-scale applications, like industrial cooling systems. They’re simple, reliable, and easy to maintain. A solid choice!

Design Considerations for Tube-in-Tube Heat Exchangers in Refrigeration

Let’s explore some important design factors for tube-in-tube heat exchangers in refrigeration systems:

Materials for Heat Exchanger Tubes

Copper and copper alloys

Copper is the most common material for heat exchanger tubes. It’s a great conductor of heat, affordable, and easy to work with. Copper alloys, like brass and bronze, are also popular choices for their added strength and corrosion resistance.

Stainless steel

Stainless steel is another popular option, especially for applications that require high corrosion resistance and durability. It’s a bit pricier than copper, but it’s worth it for the longevity and performance.

Aluminum and its alloys

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It’s an excellent choice for certain applications, especially where weight is a concern.

Geometry and Size of Tubes

Inner and outer tube diameter

The diameter of the inner and outer tubes affects the heat transfer rate and pressure drop. Bigger tubes mean more heat transfer, but also higher pressure drop. It’s a delicate balance!

Tube length and layout

Longer tubes allow for more heat transfer, but they also require more space and materials. The layout, whether straight or coiled, can also influence the heat exchanger’s performance.

Flow Arrangement and Direction

Parallel flow

In parallel flow, both fluids flow in the same direction. It’s a simple design, but not as efficient as other arrangements.

Counter flow

In counter flow, fluids flow in opposite directions. This arrangement provides more efficient heat transfer and is commonly used in tube-in-tube heat exchangers.

Cross flow

In cross flow, fluids flow perpendicular to each other. This arrangement is less common in tube-in-tube heat exchangers, but it’s worth mentioning!

Performance Evaluation of Tube-in-Tube Heat Exchangers in Refrigeration

Now, let’s talk about how to evaluate the performance of tube-in-tube heat exchangers in refrigeration systems:

Heat Transfer Rate

Overall heat transfer coefficient

The overall heat transfer coefficient measures how effective a heat exchanger is at transferring heat. Higher values mean better performance.

Log mean temperature difference (LMTD)

LMTD is a measure of the temperature difference between the two fluids. It helps determine how much heat is being transferred in the heat exchanger.

Pressure Drop and Pumping Power

Factors affecting pressure drop

Pressure drop occurs when fluids flow through the heat exchanger, and it’s influenced by factors like tube diameter, length, and flow velocity. Minimizing pressure drop is important for energy efficiency.

Influence on energy consumption

Higher pressure drop means more pumping power is needed, which increases energy consumption. So, it’s essential to strike a balance between heat transfer and pressure drop.

Fouling and Scaling

Impact on heat exchanger performance

Fouling and scaling are the buildup of deposits on the heat exchanger surfaces, reducing heat transfer efficiency and increasing pressure drop. Nobody wants that!

Prevention and maintenance strategies

Regular cleaning and using appropriate materials and coatings can help prevent fouling and scaling. A little bit of TLC goes a long way in keeping your heat exchanger in tip-top shape.

Practical Applications of Tube-in-Tube Heat Exchangers in Refrigeration Systems

Wondering where tube-in-tube heat exchangers are used in the real world? Let’s check out some practical applications:

Food and Beverage Industry

Cooling and pasteurization processes

Tube-in-tube heat exchangers are widely used for cooling and pasteurizing liquids in the food and beverage industry. They help ensure products are safe to consume and stay fresh longer.

Cold storage facilities

These heat exchangers play a crucial role in maintaining the perfect temperature in cold storage facilities, keeping your favorite snacks and drinks nice and chilled.

HVAC Systems

Chiller and heat pump systems

Tube-in-tube heat exchangers are commonly found in chiller and heat pump systems, providing efficient heating and cooling for homes and commercial buildings. They’re the unsung heroes of your comfy living space!

Waste heat recovery

These heat exchangers can also help recover waste heat from HVAC systems, boosting overall efficiency and reducing energy consumption. It’s a win-win!

Industrial Processes

Chemical and pharmaceutical industries

Tube-in-tube heat exchangers are used in the chemical and pharmaceutical industries for various cooling and heating processes, ensuring products are made safely and efficiently.

Oil and gas refining

In the oil and gas industry, these heat exchangers play a vital role in cooling and condensing processes, making sure everything runs smoothly and safely.

Future Trends and Innovations in Tube-in-Tube Heat Exchanger Refrigeration

What does the future hold for tube-in-tube heat exchanger refrigeration? Let’s explore some exciting trends and innovations:

Advances in Materials and Manufacturing Techniques

Nanofluids for enhanced heat transfer

Researchers are looking into using nanofluids, which are fluids containing nanoparticles, to enhance heat transfer in heat exchangers. This could lead to even more efficient designs!

Additive manufacturing for customized designs

Additive manufacturing, or 3D printing, is revolutionizing the way heat exchangers are made. It allows for custom designs tailored to specific applications, boosting performance and efficiency.

Integration with Renewable Energy Systems

Solar-assisted refrigeration

Tube-in-tube heat exchangers can be integrated with solar energy systems to provide eco-friendly refrigeration solutions. Harnessing the power of the sun has never been cooler!

Waste heat recovery from renewable sources

Using tube-in-tube heat exchangers to recover waste heat from renewable energy sources, like wind and solar, can further improve the efficiency of these systems. A greener future awaits!

Smart Controls and IoT Integration

Real-time performance monitoring and optimization

Smart controls and Internet of Things (IoT) integration allow for real-time monitoring and optimization of heat exchanger performance, ensuring they run at peak efficiency.

Predictive maintenance and fault detection

Advanced sensors and data analytics can help predict maintenance needs and detect faults before they become big problems, saving time and money. Now that’s smart!

Conclusion

Tube-in-tube heat exchanger refrigeration plays a significant role in our daily lives, from keeping our food fresh to maintaining comfortable temperatures in our homes and workplaces. With ongoing research and innovations, the future of tube-in-tube heat exchangers is bright and efficient. So, next time you enjoy a cold drink or a cozy room, give a little nod to the tube-in-tube heat exchanger working behind the scenes!