Types of heat exchangers in refrigeration might not be the most exciting topic, but they play a vital role in keeping your home cool and comfortable. So, what are heat exchangers, why should homeowners care and which one is right for you in a given situation? Let’s dive in!

Table of Contents

Definition and Purpose of Heat Exchangers

Heat exchangers are nifty devices that transfer heat from one fluid to another without mixing them. In refrigeration systems, they help regulate temperature by absorbing and releasing heat in different parts of the system. Pretty cool, huh?

Heat Transfer Process

Heat exchangers work through a process called conduction. When two fluids with different temperatures come into contact, heat moves from the hotter fluid to the cooler one. And that’s how the magic happens!

Role in Refrigeration Systems

Without heat exchangers, our refrigerators and air conditioners wouldn’t work. They’re the unsung heroes that keep everything cool and cozy, from your ice cream to your living room.

Classification of Heat Exchangers

There’s more than one way to transfer heat. Let’s explore the different types of heat exchangers found in refrigeration systems.

Types of Heat Exchangers in Refrigeration Based on Construction

Shell and Tube Heat Exchangers

These bad boys consist of a shell filled with tubes. One fluid flows through the tubes, while the other flows around them. It’s an oldie but a goodie!

Plate Heat Exchangers

Imagine a stack of metal plates with spaces for fluid to flow between them. That’s a plate heat exchanger! They’re compact, efficient, and easy to maintain.

Microchannel Heat Exchangers

The new kid on the block, microchannel heat exchangers are made of flat tubes with fins. They’re lightweight, offer improved heat transfer, and require less refrigerant. A winning combination!

Types of Heat Exchangers in Refrigeration Based on Flow Arrangement

Parallel-flow Heat Exchangers

In this setup, both fluids flow in the same direction. It’s like they’re having a race side by side!

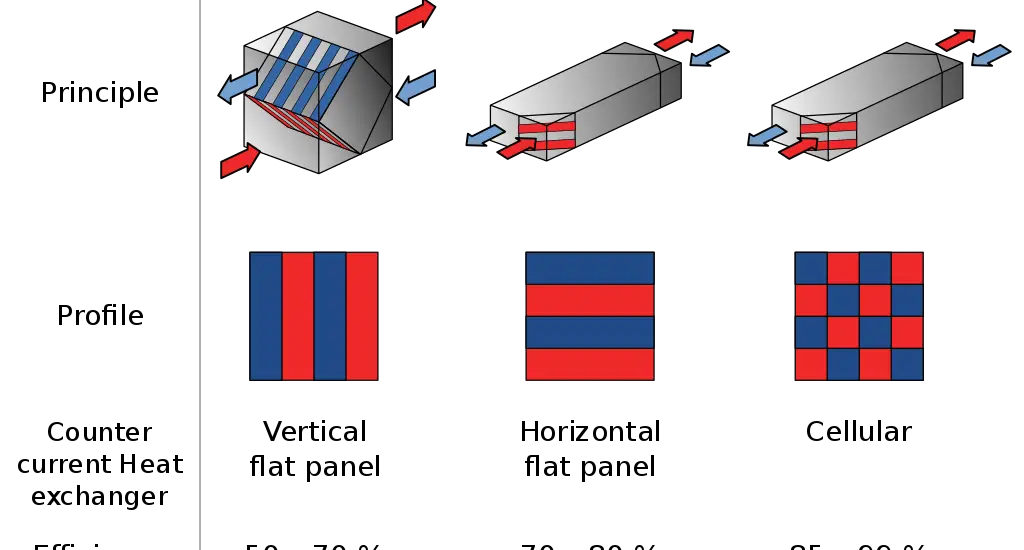

Counter-flow Heat Exchangers

Think of it as a game of chicken: the fluids flow toward each other, resulting in a more effective heat transfer. A bit risky, but it pays off!

Cross-flow Heat Exchangers

These heat exchangers are the rebels of the bunch, with fluids flowing perpendicular to each other. They don’t play by the rules, but they get the job done.

Shell and Tube Heat Exchangers

Let’s take a closer look at the classic shell and tube heat exchangers and their role in refrigeration.

Design and Construction

Shell

The shell is the outer casing that holds everything together. It’s like a giant hug for the tubes inside!

Tubes

These are the stars of the show, where the heat transfer takes place. One fluid flows inside the tubes, while the other flows around them.

Tube Sheets

Tube sheets are the bouncers of the heat exchanger, keeping the fluids separate and ensuring no mix-ups occur.

Baffles

Ever been to a party and needed a break from the crowd? Baffles create space between the tubes, giving the fluids room to breathe and optimizing heat transfer.

Types of Shell and Tube Heat Exchangers

Single-pass

These heat exchangers mean business: one pass through the tubes, and the job is done. Quick and efficient!

Multi-pass

For those who like to take their time, multi-pass heat exchangers allow the fluid to flow through the tubes more than once. It’s all about getting the most out of the experience!

U-tube

These heat exchangers bend the tubes into a U-shape, making it easier for fluids to change direction. It’s like a roller coaster ride for your refrigeration system!

Applications in Refrigeration

Evaporators

Shell and tube heat exchangers work wonders as evaporators in refrigeration systems, turning liquid refrigerant into vapor and keeping your fridge nice and chilly.

Condensers

On the flip side, they also excel as condensers, turning vapor back into liquid and releasing heat in the process. A versatile choice for your home!

Subcoolers

Want to get even more efficient? Shell and tube heat exchangers can also act as subcoolers, cooling the refrigerant liquid even further before it heads back into the system.

Plate Heat Exchangers

Now let’s explore the sleek and efficient world of plate heat exchangers.

Design and Construction

Plate Design

With their corrugated design, these plates create turbulence in the fluid flow, enhancing heat transfer. It’s like a wild ride through a heat exchanger theme park!

Plate Material

Most plate heat exchangers are made of stainless steel, a durable and corrosion-resistant material that’s perfect for the job.

Gaskets

Gaskets are the unsung heroes of plate heat exchangers, sealing the spaces between plates and preventing any pesky leaks.

Plate Arrangement

It’s all about the arrangement: alternating hot and cold fluids between the plates ensures maximum heat transfer efficiency. Talk about a well-organized party!

Types of Plate Heat Exchangers

Gasketed Plate Heat Exchangers

These are the classic plate heat exchangers, held together by gaskets that can be easily replaced if needed. Maintenance made easy!

Brazed Plate Heat Exchangers

Brazed plate heat exchangers use copper or nickel to join the plates, creating a strong and leak-proof bond. They’re like the superglue of heat exchangers!

Welded Plate Heat Exchangers

For the ultimate in durability, welded plate heat exchangers fuse the plates together with no gaskets required. They’re built to last!

Applications in Refrigeration

Evaporators

Plate heat exchangers make excellent evaporators, turning liquid refrigerant into vapor and keeping your home cool and comfortable.

Condensers

They also shine as condensers, releasing heat and turning vapor back into liquid. Efficiency at its finest!

Economizers

Want to save even more energy? Plate heat exchangers can be used as economizers, pre-cooling the refrigerant before it enters the compressor. Your wallet will thank you!

Microchannel Heat Exchangers

Last but not least, let’s take a look at the innovative microchannel heat exchangers and their benefits.

Design and Construction

Microchannel Tubes

These tiny tubes are the stars of the show in microchannel heat exchangers, providing a large surface area for efficient heat transfer. It’s amazing what a little innovation can do!

Fin Material

Aluminum fins are common in microchannel heat exchangers, offering great heat transfer properties and corrosion resistance. A lightweight and durable choice!

Manifold Design

Manifolds help distribute the fluid evenly throughout the microchannel tubes. They’re like the traffic cops of the heat exchanger world!

Advantages of Microchannel Heat Exchangers

Compact Size

Microchannel heat exchangers are the ultimate space-savers, with their compact and lightweight design. Perfect for smaller homes or tight spaces!

Enhanced Heat Transfer

With their large surface area and innovative design, microchannel heat exchangers offer improved heat transfer efficiency. It’s like upgrading your car’s engine for better performance!

Reduced Refrigerant Charge

These heat exchangers require less refrigerant than their counterparts, making them a more environmentally friendly choice. It’s a win-win!

Applications in Refrigeration

Evaporators

Microchannel heat exchangers make fantastic evaporators, providing efficient cooling and keeping your home comfortable.

Condensers

They also excel as condensers, effectively releasing heat and keeping your refrigeration system running smoothly.

Gas Coolers

For those looking to go the extra mile, microchannel heat exchangers can also be used as gas coolers in transcritical CO2 refrigeration systems. Talk about cutting-edge technology!

Selection and Sizing of Heat Exchangers

Now that we’ve explored the different types of heat exchangers, how do you choose the right one for your home? Let’s find out!

Factors to Consider

Heat Transfer Requirements

First and foremost, consider your home’s cooling needs. Bigger isn’t always better – make sure you choose a heat exchanger that’s just the right size for your system.

Refrigerant Type

Different heat exchangers work best with different refrigerants. Make sure to choose one that’s compatible with your system’s refrigerant type.

Space Constraints

Got limited space? Opt for a compact heat exchanger like a plate or microchannel model. They’ll fit right in!

Cost and Maintenance

Last but not least, consider the initial cost and ongoing maintenance requirements of your heat exchanger. Choose one that fits your budget and is easy to maintain.

Sizing Methods

Log Mean Temperature Difference (LMTD) Method

One way to size your heat exchanger is by using the LMTD method. It considers the temperature difference between the fluids and helps you find the perfect fit.

Effectiveness-NTU (ε-NTU) Method

The ε-NTU method is another option for sizing your heat exchanger, focusing on the effectiveness of the heat transfer process. It’s like finding a tailor-made solution for your home!

Conclusion

Importance of Proper Selection

Choosing the right heat exchanger for your refrigeration system is crucial for maintaining a cool and comfortable home. Don’t leave it to chance – make an informed decision and enjoy the benefits!

Advancements in Heat Exchanger Technology

As technology continues to evolve, so do heat exchangers. Keep an eye on the latest developments and be ready to upgrade when the time is right. Your home (and your energy bill) will thank you!