Thanks to the vapor compression cycle, your refrigerator or air conditioner keeps things cool and comfortable. So, what is it exactly? Well, you’re in good company because we will walk you through the concept in this article….

Table of Contents

Definition and Purpose

The vapor compression cycle is a thermodynamic process that transfers heat from a low-temperature area to a high-temperature area using a refrigerant. It’s the secret behind how your fridge and AC keep things cool, by absorbing heat from inside and dumping it outside. Pretty neat, huh?

Key Components

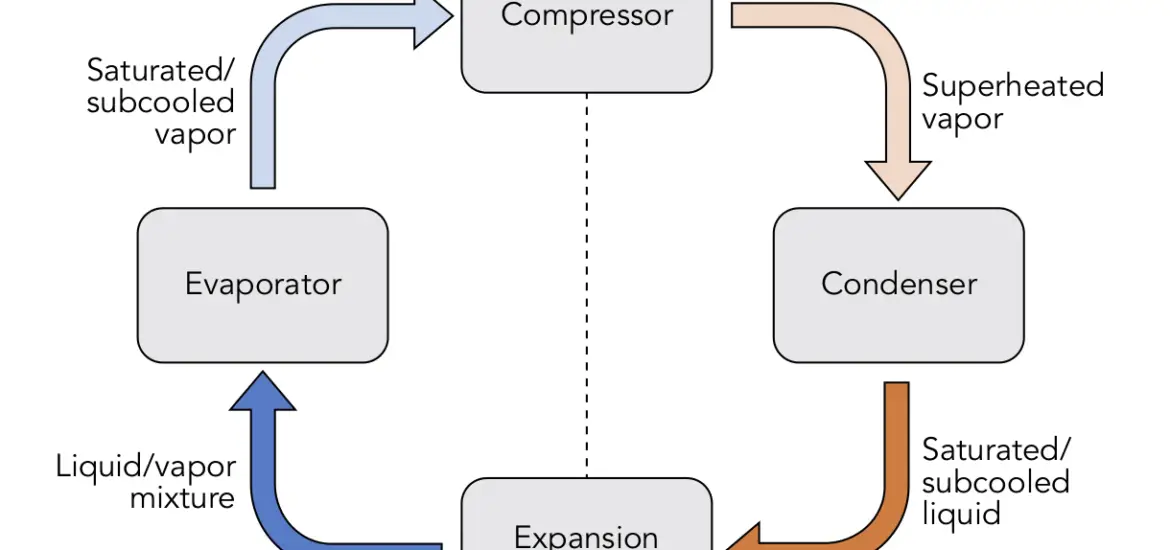

There are four main components in the vapor compression cycle: the compressor, condenser, expansion device, and evaporator. These parts work together to make the magic happen, and we’ll explore each of them in detail later on.

Basic Principles

The vapor compression cycle works by circulating a refrigerant through a continuous loop. The refrigerant absorbs heat, turns into vapor, and then releases the heat as it condenses back into a liquid. This process keeps your home cool and comfy!

Types of Vapor Compression Refrigeration Systems

There are several types of vapor compression refrigeration systems, each designed for different applications. Here are the main ones:

Direct Expansion (DX) Systems

Direct Expansion (DX) systems are the most common type of vapor compression refrigeration system. In these systems, the refrigerant evaporates directly inside the cooling coil, absorbing heat from the surrounding air. You’ll find DX systems in most residential air conditioners and refrigerators.

Chilled Water Systems

Chilled water systems use a secondary coolant, usually water, to transfer heat between the evaporator and the cooling coil. These systems are popular in large commercial and industrial applications, where they provide efficient cooling for multiple spaces.

Absorption Refrigeration Systems

Absorption refrigeration systems use a different process than the vapor compression cycle, but they still achieve the same goal: cooling. In these systems, a heat source drives the refrigeration process, making them ideal for applications where excess heat is available, such as solar or waste heat recovery.

Components of Vapor Compression Cycle

Now let’s take a closer look at the main components of the vapor compression cycle and see how they work together to keep things cool.

Compressor

Function

The compressor is the heart of the vapor compression cycle. It takes in the low-pressure, low-temperature refrigerant vapor from the evaporator and compresses it to a high-pressure, high-temperature vapor. This process adds energy to the refrigerant, allowing it to release heat as it moves through the condenser.

Types of Compressors

There are several types of compressors used in vapor compression systems, each with its own advantages and disadvantages. Here are some of the most common ones:

Reciprocating Compressors

Reciprocating compressors use a piston and cylinder arrangement to compress the refrigerant. They’re widely used in residential and small commercial applications due to their simplicity and reliability.

Rotary Compressors

Rotary compressors use rotating components, such as vanes or screws, to compress the refrigerant. These compressors are more compact and quieter than reciprocating compressors, making them popular in air conditioning systems.

Scroll Compressors

Scroll compressors use two spiral-shaped scrolls to compress the refrigerant. They’re known for their high efficiency, low noise, and excellent reliability, making them a popular choice for residential and commercial air conditioning systems.

Screw Compressors

Screw compressors use two meshing helical screws to compress the refrigerant. They’re suitable for large commercial and industrial applications due to their high capacity and efficiency.

Centrifugal Compressors

Centrifugal compressors use a rotating impeller to compress the refrigerant. These compressors are typically found in large-scale applications like chilled water systems and industrial processes.

Condenser

Function

The condenser is where the high-pressure, high-temperature refrigerant vapor releases its heat to the surroundings. As the refrigerant loses heat, it condenses back into a liquid, ready to be expanded and evaporated again.

Types of Condensers

There are several types of condensers used in vapor compression systems, each with its own advantages and disadvantages. Here are some of the most common ones:

Air-cooled Condensers

Air-cooled condensers use air to remove heat from the refrigerant. These condensers are simple, inexpensive, and commonly used in residential and small commercial applications.

Water-cooled Condensers

Water-cooled condensers use water to remove heat from the refrigerant. They’re more efficient than air-cooled condensers, especially in hot climates, but require a continuous water supply and additional maintenance.

Evaporative Condensers

Evaporative condensers combine the principles of air-cooled and water-cooled condensers to achieve high efficiency. They use a combination of air and water to remove heat from the refrigerant, making them suitable for large-scale applications.

For more articles on vapor refrigeration, click here.

Expansion Device

Function

The expansion device reduces the pressure and temperature of the liquid refrigerant, allowing it to absorb heat as it evaporates in the evaporator. There are several types of expansion devices, each with its own advantages and disadvantages.

Types of Expansion Devices

Here are some of the most common expansion devices used in vapor compression systems:

Capillary Tubes

Capillary tubes are small-diameter tubes that create a pressure drop as the refrigerant flows through them. They’re simple, inexpensive, and commonly used in small residential and commercial applications.

Thermostatic Expansion Valves (TXV)

Thermostatic Expansion Valves (TXV)Thermostatic Expansion Valves (TXV)Thermostatic Expansion Valves (TXVs) are more sophisticated than capillary tubes, as they can adjust the flow of refrigerant according to the cooling load. This makes them more energy-efficient and better suited for a wide range of applications, from residential to large commercial systems.

Electronic Expansion Valves (EEV)

Electronic Expansion Valves (EEVs) are similar to TXVs but use electronic sensors and controls to regulate the refrigerant flow. This allows for even greater precision and efficiency, making them a popular choice in modern, high-performance systems.

Evaporator

Function

The evaporator is where the low-pressure, low-temperature refrigerant absorbs heat from its surroundings, turning from a liquid into a vapor. This process cools the air or water passing over the evaporator, providing the desired cooling effect.

Types of Evaporators

There are several types of evaporators used in vapor compression systems, each with its own advantages and disadvantages. Here are some of the most common ones:

Plate Evaporators

Plate evaporators use a series of thin, flat plates to transfer heat between the refrigerant and the air or water being cooled. They’re compact, efficient, and suitable for a wide range of applications.

Shell-and-tube Evaporators

Shell-and-tube evaporators use a bundle of tubes inside a larger shell to transfer heat between the refrigerant and the air or water being cooled. They’re commonly used in large commercial and industrial applications due to their high capacity and robust design.

Finned-tube Evaporators

Finned-tube evaporators use tubes with fins attached to increase the heat transfer surface area. This design improves efficiency and is commonly used in air conditioning and refrigeration systems.

Refrigerants and their Properties

Definition and Role in Vapor Compression Cycle

Refrigerants are substances that undergo phase changes (from liquid to vapor and vice versa) within the vapor compression cycle to provide cooling. Their properties, such as boiling point, pressure, and heat capacity, are critical to the performance and efficiency of the system.

Classification of Refrigerants

Refrigerants can be classified into several categories based on their chemical composition and properties:

Chlorofluorocarbons (CFCs)

CFCs were once widely used as refrigerants due to their excellent thermodynamic properties and low toxicity. However, they have been phased out because they contribute to ozone depletion and have a high global warming potential (GWP).

Hydrochlorofluorocarbons (HCFCs)

HCFCs were introduced as a temporary replacement for CFCs, as they have lower ozone depletion potential. However, they still contribute to ozone depletion and have a high GWP, so they are also being phased out.

Hydrofluorocarbons (HFCs)

HFCs do not contribute to ozone depletion but have a high GWP. They are currently used in many applications, but efforts are being made to replace them with more environmentally friendly alternatives.

Natural Refrigerants

Natural refrigerants, such as ammonia, carbon dioxide, and hydrocarbons, have gained popularity in recent years due to their low environmental impact. They have negligible ozone depletion potential and lower global warming potential compared to synthetic refrigerants. However, they may have other challenges, such as flammability or toxicity, that need to be addressed in system design and operation.

Selection Criteria for Refrigerants

When selecting a refrigerant for a vapor compression system, several factors need to be considered:

Thermodynamic Properties

The refrigerant’s boiling point, pressure, heat capacity, and other thermodynamic properties should be suitable for the intended application and operating conditions.

Environmental Impact

The refrigerant’s ozone depletion potential and global warming potential should be minimal to reduce its environmental impact.

Safety and Toxicity

Refrigerants should be non-toxic and have low flammability to ensure the safety of people and property.

Cost and Availability

The refrigerant should be readily available and affordable, considering both its initial cost and long-term operating expenses.

Vapor Compression Cycle Analysis

Pressure-Enthalpy (P-h) Diagram

Understanding the P-h Diagram

A Pressure-Enthalpy (P-h) diagram is a graphical representation of the vapor compression cycle, showing how the refrigerant’s properties change as it moves through the system. It’s a powerful tool for understanding and analyzing the performance and efficiency of a refrigeration system.

Plotting the Vapor Compression Cycle

By plotting the vapor compression cycle on a P-h diagram, engineers can visualize the refrigerant’s phase changes and energy transfers throughout the system. This helps them optimize system design and operating conditions to improve performance and efficiency.

Coefficient of Performance (COP)

Definition and Calculation

The Coefficient of Performance (COP) is a measure of a refrigeration system’s efficiency, defined as the ratio of the cooling effect to the work input. A higher COP indicates a more energy-efficient system.

Factors Affecting COP

Several factors can influence a system’s COP, including the refrigerant properties, compressor efficiency, heat exchanger performance, and operating conditions. By optimizing these factors, the COP can be improved, resulting in lower energy consumption and operating costs.

Improving Efficiency of Vapor Compression Cycle

Multistage Compression

Multistage compression uses multiple compressors in series to compress the refrigerant in stages, which can significantly improve efficiency by reducing the work input required for each compression stage.

Subcooling and Superheating

Subcooling (cooling the liquid refrigerant below its saturation temperature) and superheating (heating the vapor refrigerant above its saturation temperature) can enhance system performance and efficiency by improving heat transfer and reducing the risk of liquid refrigerant entering the compressor.

Evaporative Cooling

Evaporative cooling uses the evaporation of water to remove heat from the refrigerant, which can improve the efficiency of the condenser and reduce energy consumption.

Heat Recovery

Heat recovery systems capture waste heat from the refrigeration process and use it for other purposes, such as space heating or hot water production. This not only improves the overall system efficiency but also reduces the energy consumption and environmental impact of the vapor compression cycle.

Vapor Compression Refrigeration Impact

Environmental Impact

Ozone Depletion

Some refrigerants, particularly CFCs and HCFCs, have been linked to ozone depletion. As a result, their production and use have been phased out or limited under international agreements such as the Montreal Protocol.

Global Warming Potential (GWP)

Refrigerants also contribute to global warming by trapping heat in the atmosphere. The Global Warming Potential (GWP) of a refrigerant is a measure of its ability to contribute to global warming compared to carbon dioxide. Efforts have been made to shift towards refrigerants with lower GWP values to reduce their environmental impact.

Energy Consumption and Efficiency

Reducing Energy Consumption

Improving the efficiency of vapor compression systems can significantly reduce their energy consumption and operating costs. This can be achieved through system design optimization, proper maintenance, and incorporating advanced technologies and control strategies.

Energy-efficient Technologies

Some energy-efficient technologies that can be used in vapor compression systems include variable-speed compressors, heat recovery systems, and evaporative cooling. These technologies can help minimize energy consumption and environmental impact while maintaining or improving system performance.

Legislation and Regulations

Montreal Protocol

The Montreal Protocol is an international treaty designed to protect the ozone layer by phasing out the production and consumption of ozone-depleting substances, including certain refrigerants like CFCs and HCFCs.

Kyoto Protocol

The Kyoto Protocol is an international agreement aimed at reducing greenhouse gas emissions, which include some refrigerants with high GWP values. It encourages countries to adopt more environmentally friendly refrigeration technologies and practices.

Kigali Amendment

The Kigali Amendment to the Montreal Protocol seeks to phase down the production and consumption of HFCs, which have high GWP values but do not deplete the ozone layer. This amendment aims to further reduce the environmental impact of refrigeration systems.

Regional and National Regulations

Various regional and national regulations govern the use and handling of refrigerants and refrigeration systems to minimize their environmental impact and ensure safety. These regulations may include restrictions on the types of refrigerants that can be used, as well as requirements for proper maintenance and leak detection.

Future Trends in Vapor Compression Refrigeration

Green Refrigerants and Eco-friendly Alternatives

Hydrofluoroolefins (HFOs)

Hydrofluoroolefins (HFOs) are a class of synthetic refrigerants with low GWP values, which make them an eco-friendly alternative to traditional HFCs. HFOs are gaining popularity in the industry due to their reduced environmental impact and favorable thermodynamic properties.

Carbon Dioxide (CO2)

Carbon dioxide (CO2) is a natural refrigerant with a low GWP value and excellent thermodynamic properties, making it a promising alternative for various refrigeration applications. However, it operates at higher pressures than most conventional refrigerants, requiring specialized equipment and system designs.

Ammonia (NH3)

Ammonia (NH3) is a natural refrigerant with exceptional thermodynamic properties and a GWP of zero. It has been used for many years in industrial refrigeration systems. However, ammonia is toxic and requires strict safety measures and proper handling during installation and maintenance.

Hydrocarbons (HCs)

Hydrocarbons, such as propane (R290) and isobutane (R600a), are natural refrigerants with low GWP values and excellent thermodynamic properties. They are gaining popularity in small refrigeration systems and domestic appliances. However, they are flammable and require careful handling and safety measures.

Advanced Technologies in Vapor Compression Cycle

Magnetic Refrigeration

Magnetic refrigeration is an emerging technology that uses magnetic fields to create a cooling effect. It has the potential to be more energy-efficient and environmentally friendly than traditional vapor compression systems but is still in the early stages of development and commercialization.

Thermoacoustic Refrigeration

Thermoacoustic refrigeration uses sound waves to generate cooling effects, offering a potential alternative to vapor compression systems. This technology is still in the research and development phase, but it could provide an energy-efficient and environmentally friendly cooling solution in the future.

Thermoelectric Refrigeration

Thermoelectric refrigeration uses the Peltier effect to create cooling by applying a voltage across a thermoelectric material. This technology has no moving parts, making it reliable and low-maintenance, but its efficiency is currently lower than that of vapor compression systems.

Solar-Powered Refrigeration

Solar-powered refrigeration systems use solar energy to power vapor compression cycles, reducing their reliance on grid electricity and lowering their environmental impact. These systems are particularly beneficial in remote areas with limited access to reliable electricity sources.

Internet of Things (IoT) and Smart Refrigeration Systems

IoT-enabled Sensors and Controls

Internet of Things (IoT) technology enables the integration of sensors and control systems in refrigeration systems, allowing for real-time monitoring and optimization of system performance. This can help improve efficiency, reduce energy consumption, and prolong the life of system components.

Energy Management and Optimization

Smart refrigeration systems can use advanced algorithms and data analysis to optimize energy consumption and system performance. By adapting to changing conditions and demands, these systems can reduce energy usage and operating costs while maintaining or improving cooling performance.

Predictive Maintenance and Remote Monitoring

IoT-enabled refrigeration systems can monitor component performance and predict potential failures, allowing for preventative maintenance and reducing downtime. Remote monitoring capabilities also enable technicians to diagnose and resolve issues without the need for on-site visits.

Applications of Vapor Compression Cycle

Residential Applications

Domestic Refrigerators and Freezers

Vapor compression cycles are commonly used in domestic refrigerators and freezers to keep food fresh and frozen. These appliances are essential in modern households, helping to preserve perishable food items and reduce food waste.

Air Conditioning Systems

Air conditioning systems in residential buildings often use vapor compression cycles to provide cooling and maintain comfortable indoor temperatures. These systems are especially important in hot climates where they provide relief from high temperatures and humidity.

Commercial Applications

Supermarkets and Cold Storage Facilities

Commercial refrigeration systems, such as those used in supermarkets and cold storage facilities, rely on vapor compression cycles to maintain proper temperatures for food storage. These systems help preserve perishable goods and ensure food safety and quality.

Food Processing and Preservation

Vapor compression refrigeration is used in various stages of food processing and preservation, from chilling and freezing to transportation and storage. This helps maintain the quality and safety of food products throughout the supply chain.

Industrial Applications

Chemical and Pharmaceutical Industries

Temperature control is crucial in chemical and pharmaceutical industries, where vapor compression refrigeration systems are often used to maintain specific temperatures during production, storage, and transportation of sensitive materials.

Data Centers and Electronic Equipment Cooling

Data centers and electronic equipment generate significant heat during operation, which can be detrimental to their performance and longevity. Vapor compression cooling systems help maintain optimal temperatures, ensuring reliable operation and preventing overheating-related failures.

Safety and Maintenance of Vapor Compression Systems

Safety Considerations

Pressure Relief Devices

Pressure relief devices, such as pressure relief valves, are crucial safety components in vapor compression systems. They help protect the system from over-pressurization, which can lead to equipment damage or even catastrophic failure.

Refrigerant Leak Detection and Monitoring

Refrigerant leaks can pose significant safety risks and environmental concerns. Leak detection and monitoring systems help identify leaks early, allowing for prompt repairs and preventing potential hazards.

Proper Ventilation and Equipment Handling

Proper ventilation is essential in areas where refrigeration systems are installed, as it helps disperse any refrigerant leaks and minimize the risk of exposure. Additionally, following proper equipment handling procedures and safety guidelines is crucial to prevent accidents and injuries during installation and maintenance.

Maintenance and Inspection

Regular Maintenance Schedule

Establishing a regular maintenance schedule for vapor compression systems helps ensure optimal performance, energy efficiency, and system longevity. Regular maintenance can also help prevent costly breakdowns and downtime.

Cleaning and Inspection of Components

Regular cleaning and inspection of system components, such as evaporators, condensers, and compressors, can help identify potential issues before they become critical. This can help prevent system failures and prolong the life of the equipment.

Refrigerant Charge and Leak Repair

Maintaining the proper refrigerant charge is essential for the efficient operation of vapor compression systems. Regular leak checks and prompt repairs help maintain the correct charge and minimize the environmental impact of refrigerant leaks.

Lubrication and Compressor Maintenance

Proper lubrication and compressor maintenance are critical for the reliable operation of vapor compression systems. Regular maintenance helps ensure smooth and efficient compressor operation, reducing wear and extending the life of the equipment.

Conclusion

Importance of Vapor Compression Cycle in Modern Society

The vapor compression cycle plays a vital role in modern society, providing cooling and temperature control in a wide range of residential, commercial, and industrial applications. Its importance cannot be overstated, as it helps maintain food safety, supports critical industries, and provides comfort in our daily lives.

As the demand for cooling continues to grow, it is crucial to strive for greater energy efficiency and sustainability in vapor compression systems. Advancements in technology, the adoption of environmentally friendly refrigerants, and improved system design can help reduce the environmental impact and conserve valuable resources.

Future Developments and Innovations in Vapor Compression Refrigeration

Emerging technologies, such as magnetic refrigeration, thermoacoustic refrigeration, and solar-powered refrigeration, hold great promise for the future of vapor compression refrigeration. Additionally, the integration of IoT and smart refrigeration systems can lead to improved efficiency, reduced energy consumption, and better overall performance. As we continue to develop and innovate, the vapor compression cycle will remain a cornerstone of modern cooling technology.