Ever wondered how we keep our food fresh and our buildings cool? It’s all thanks to the vapor compression refrigeration cycle with ejector! In this article, we’ll dive into the world of refrigeration cycles, explaining how they work and how ejector technology enhances their performance. So buckle up and get ready for a cool ride!

Table of Contents

Refrigeration Cycle Overview

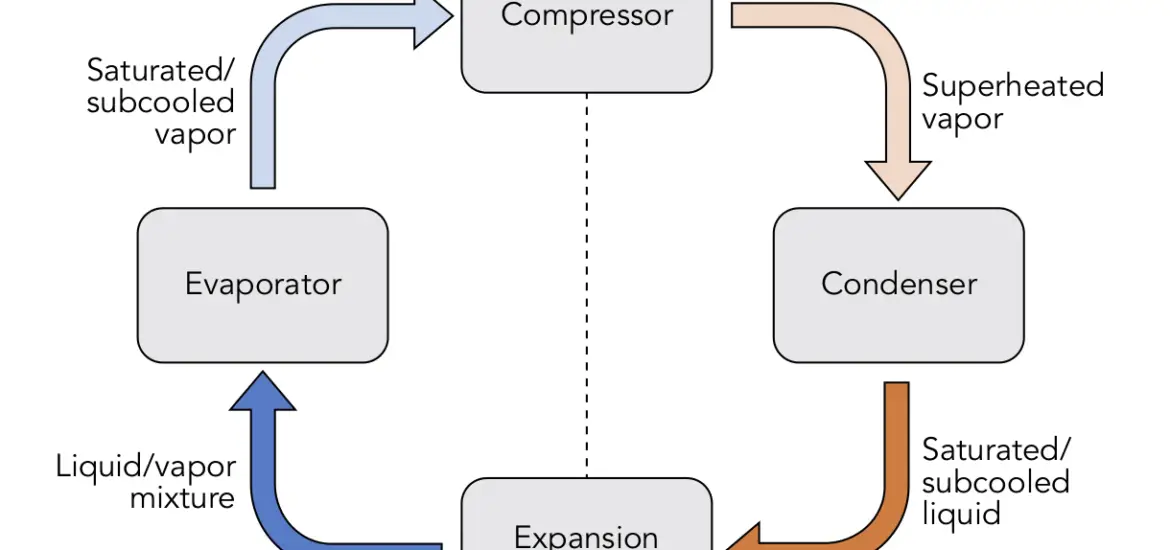

The refrigeration cycle is the backbone of modern cooling systems, using a refrigerant to transfer heat from one area to another. In a nutshell, the cycle consists of four main stages: compression, condensation, expansion, and evaporation. The vapor compression refrigeration cycle is the most widely used type of cycle, thanks to its efficiency and versatility.

Ejector in Refrigeration Cycle

So what’s the deal with ejectors? An ejector is a device that uses the energy of a high-velocity fluid to compress a lower pressure fluid, improving the overall efficiency of the refrigeration cycle. Ejector-based systems offer a range of benefits, including reduced energy consumption, lower maintenance costs, and enhanced performance.

Components of the Vapor Compression Refrigeration Cycle with Ejector

Compressor

Meet the heart of the refrigeration cycle: the compressor. Its job is to compress the refrigerant vapor, increasing its pressure and temperature. There are different types of compressors, each with its own set of pros and cons. The performance of a compressor is influenced by factors like its design, operating conditions, and the refrigerant used.

Ejector

Now, let’s talk ejectors. These nifty devices operate on the principle of converting kinetic energy into pressure energy, essentially “sucking” low-pressure refrigerant vapor and compressing it. There are various types of ejectors, each with its own unique design and characteristics. The performance of an ejector is influenced by factors such as its geometry, operating conditions, and the refrigerant used.

Condenser

The condenser’s role in the refrigeration cycle is to release heat from the high-pressure refrigerant vapor, turning it into a liquid. There are several types of condensers, each suited for different applications and environments. The performance of a condenser is affected by factors like its design, operating conditions, and the refrigerant used.

Expansion Valve

Next up, the expansion valve. This component’s purpose is to regulate the flow of refrigerant into the evaporator, reducing its pressure and temperature. There are various types of expansion valves, each with its own set of advantages and disadvantages. The performance of an expansion valve is influenced by factors like its design, operating conditions, and the refrigerant used.

Evaporator

Last but not least, the evaporator. Its job is to absorb heat from the surrounding environment, causing the refrigerant to evaporate and cool down. There are different types of evaporators, each with its own unique design and characteristics. The performance of an evaporator is influenced by factors such as its design, operating conditions, and the refrigerant used.

Read other in-depth articles on vapor refrigeration here: Vapor Refrigeration: Easy Guide to Keeping Things Chill

The Vapor Compression Refrigeration Cycle with Ejector

Cycle Description

Alright, now that we’ve covered the main components, let’s dive into the vapor compression refrigeration cycle with ejector. The basic cycle stages remain the same, but with the addition of an ejector. The ejector is integrated into the cycle between the evaporator and the compressor, using a high-velocity working fluid to compress the low-pressure refrigerant vapor before it enters the compressor.

Thermodynamic Analysis

Time to put on our lab coats and explore the science behind it all. A pressure-enthalpy diagram helps us visualize the cycle’s thermodynamic processes. The ejector’s working principle allows it to recover energy that would otherwise be wasted, improving the system’s performance in several ways:

Pressure Recovery

By compressing the low-pressure refrigerant vapor, the ejector increases its pressure, reducing the work required by the compressor. This leads to a more energy-efficient system.

Flash Gas Removal

Ejectors play a key role in removing flash gas, which is vapor formed during the expansion process. This improves the evaporator’s efficiency, as more refrigerant is available for evaporation and heat transfer.

Enthalpy Recovery

Ejectors can also recover enthalpy, or the energy content of the refrigerant, by mixing high- and low-pressure streams. This reduces the overall energy consumption of the system and improves its performance.

Applications of Vapor Compression Refrigeration Cycle with Ejector

Industrial Refrigeration

From keeping our food fresh to maintaining precise temperatures in chemical processes, ejector-based vapor compression refrigeration systems are widely used in the industrial sector. Some common applications include food processing, chemical and pharmaceutical manufacturing, and cold storage facilities.

Commercial Refrigeration

Ever shopped at a supermarket or enjoyed a cold beverage at a restaurant? Ejector-based systems are also used in commercial refrigeration applications like supermarkets, air conditioning systems, and ice-making machines.

Residential Refrigeration

But wait, there’s more! Ejector-based refrigeration systems can also be found in our homes, keeping our food fresh in refrigerators and freezers, and providing comfort through heat pump systems.

Conclusion

Summary of Key Points

To wrap it up, the ejector plays a crucial role in enhancing the performance of the vapor compression refrigeration cycle. By integrating an ejector, we can achieve a more energy-efficient system with lower maintenance costs and improved performance. Ejector-based systems are used in a wide range of applications, from industrial and commercial settings to residential refrigeration.

Future Prospects

With advances in ejector technology and growing concerns about energy consumption and environmental impact, the potential for energy savings and increased efficiency is significant. As research and development in this field continue, we can look forward to even more innovative and sustainable cooling solutions in the future.