Vapour compression refrigeration systems are the key to keeping your home cool and comfy during those scorching summer days! So how do these amazing systems work to maintain a comfortable environment for you and your family? In this guide, we’ll walk you through everything you need to know about vapor compression refrigeration systems. So grab a cold drink, kick back, and let’s dive in!

Table of Contents

Introduction to Vapour Compression Refrigeration Systems

First things first, let’s talk about what vapour compression refrigeration systems actually are. These systems are the most common type of cooling system used in homes, and they’re based on some pretty cool science (pun intended).

Definition of Vapour Compression Refrigeration Systems

Vapor Refrigerant Definition

A vapor refrigerant is simply a substance that absorbs heat as it evaporates and releases heat as it condenses. These refrigerants are the key to keeping your home cool!

Vapor Refrigerant Meaning

So what does “vapor refrigerant” really mean? It refers to the substance that’s responsible for the cooling process in your home’s air conditioning system. Cool, right?

Applications of Vapour Compression Refrigeration Systems

Now that you know what they are, let’s talk about where you’ll find these systems in action.

Vapor Compression Refrigeration for Air Conditioning

One of the most common uses of vapour compression refrigeration systems is in residential air conditioning units. They’re the reason you can enjoy a cool, comfortable home even on the hottest days of the year!

Vapor Cycle Refrigeration Unit

Another application of these systems is in vapor cycle refrigeration units, which are used in commercial and industrial settings to maintain the proper temperature for food storage, pharmaceuticals, and more.

Read other detailed articles on vapor refrigeration systems here: Vapor Refrigeration: Easy Guide to Keeping Things Chill

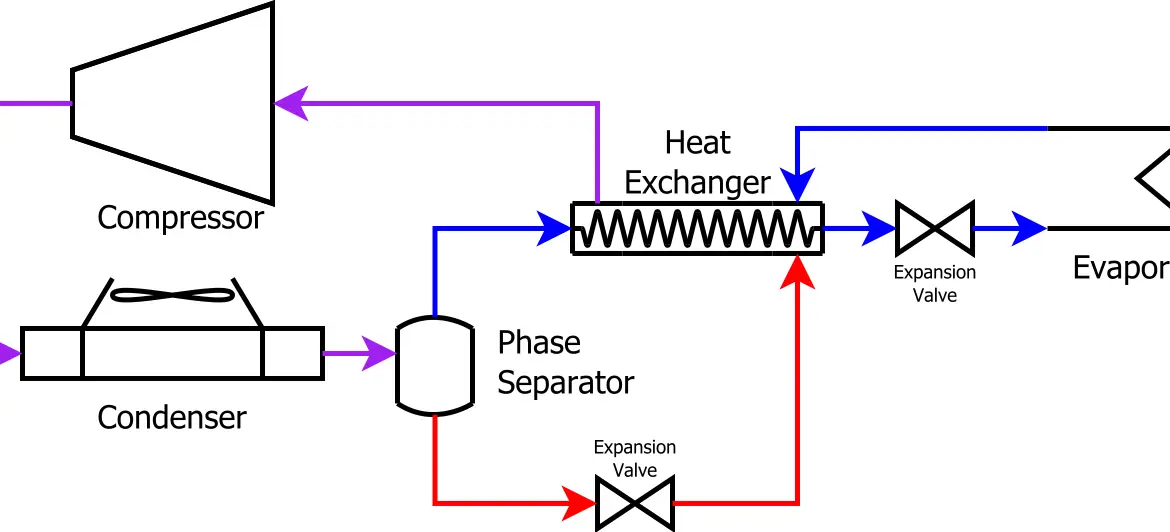

Components of Vapor Compression Refrigeration System

Now let’s take a closer look at the parts that make up a vapour compression refrigeration system.

Compressor

Types of Compressors

There are different types of compressors used in these systems, including reciprocating, rotary, and scroll compressors. Each has its own advantages and disadvantages, but they all serve the same purpose: to compress the refrigerant vapor.

Function of Compressor in Vapor Compression Cycle

So why do we need a compressor? As the refrigerant vapor is compressed, its temperature and pressure increase. This high-pressure, high-temperature vapor is then sent to the condenser, where it releases heat and transforms back into a liquid.

Condenser

Types of Condensers

Condensers can be air-cooled, water-cooled, or evaporative. They all do the same job: cooling the high-pressure refrigerant vapor and turning it back into a liquid.

Function of Condenser in Vapor Compression Cycle

The condenser’s job is to release the heat absorbed by the refrigerant vapor during the evaporation phase. This is crucial because it allows the refrigerant to cool down and be ready for the next phase of the cycle.

Expansion Valve

Types of Expansion Valves

There are several types of expansion valves, such as thermostatic expansion valves (TXVs), capillary tubes, and automatic expansion valves. Each of these has its own unique way of controlling the flow of refrigerant into the evaporator.

Function of Expansion Valve in Vapor Compression Cycle

So what’s the purpose of the expansion valve? As the high-pressure liquid refrigerant flows through the valve, its pressure drops, causing it to partially evaporate and cool down. This cool mixture of liquid and vapor refrigerant is then sent to the evaporator to absorb heat from your home.

Evaporator

Types of Evaporators

There are various types of evaporators, like plate, finned-tube, and shell-and-tube evaporators. Regardless of their design, they all have one goal: to absorb heat from the air inside your home.

Function of Evaporator in Vapor Compression Cycle

The evaporator is where the magic happens. As the cold refrigerant flows through the evaporator coils, it absorbs heat from the surrounding air, causing the refrigerant to evaporate. This cooled air is then blown back into your home, keeping you nice and comfy!

The Vapor Compression Refrigeration Cycle

Now that we know the key components, let’s take a closer look at the whole cycle in action.

Overview of the Vapor Compression Refrigeration Cycle

What is Vapor Compression Refrigeration Cycle

The vapor compression refrigeration cycle is a continuous process that involves the four main components we just discussed: compressor, condenser, expansion valve, and evaporator. This cycle keeps your home cool and comfortable by absorbing, transferring, and releasing heat.

Working of Vapor Compression Refrigeration System

So how does it all come together? In a nutshell, the refrigerant absorbs heat in the evaporator, gets compressed and heated in the compressor, releases heat in the condenser, and finally, expands and cools in the expansion valve. Then, the cycle repeats!

Vapor Compression Cycle Phases

Now, let’s break down each phase of the cycle in more detail.

Compression Phase

During the compression phase, the compressor takes the low-pressure refrigerant vapor from the evaporator and compresses it, increasing its temperature and pressure. This prepares the refrigerant for the next phase: condensation.

Condensation Phase

In the condensation phase, the high-pressure, high-temperature refrigerant vapor travels through the condenser coils, where it releases heat to the surrounding air (or water) and transforms back into a liquid state. This cooled liquid refrigerant is now ready to move on to the expansion phase.

Refrigerant Vapor Phase

After the refrigerant has passed through the expansion valve and its pressure has dropped, it enters the refrigerant vapor phase.

Evaporation Phase

In the evaporation phase, the refrigerant absorbs heat from the air inside your home, causing it to evaporate and cool the air in the process. This cooled air is then circulated throughout your home, keeping you comfortable and happy!

Performance Parameters

Coefficient of Performance (COP)

The coefficient of performance (COP) is a measure of how efficient a vapor compression refrigeration system is. In simple terms, it’s the ratio of the cooling effect produced by the system to the amount of energy consumed. A higher COP means a more efficient system, which can save you money on energy bills!

Efficiency of Vapor Compression Refrigeration System

The efficiency of a vapor compression refrigeration system depends on various factors, such as the type of compressor, condenser, and evaporator used, as well as the quality of the refrigerant and the overall design of the system. Regular maintenance and proper sizing of the system also play a significant role in maintaining high efficiency.

Types of Vapour Compression Refrigeration Systems

There are a few different types of vapour compression refrigeration systems to choose from, depending on your specific needs and preferences.

Direct Expansion (DX) System

A direct expansion (DX) system is the most common type of residential air conditioning system. In a DX system, the refrigerant flows directly through the evaporator coils, where it absorbs heat from the air inside your home.

Chilled Water System

A chilled water system is often used in larger commercial or industrial applications. Instead of using refrigerant directly, this type of system uses chilled water to transfer heat between the evaporator and the air inside the building.

Secondary Coolant System

In a secondary coolant system, an additional coolant (like glycol) is used to transfer heat between the evaporator and the area that needs cooling. These systems are typically found in specialized applications like ice rinks or cold storage facilities.

Advantages and Disadvantages of Vapor Compression Refrigeration Systems

Now that we’ve covered the basics, let’s weigh the pros and cons of vapor compression refrigeration systems.

Advantages of Vapor Compression Refrigeration Systems

Energy Efficiency

Vapor compression refrigeration systems can be highly energy-efficient, especially when properly sized and maintained. This can lead to significant savings on your energy bills over time.

Scalability

These systems are highly scalable, which means they can be easily adapted to fit the cooling needs of various applications, from small residential units to large commercial installations.

Wide Range of Applications

As we’ve discussed, vapor compression refrigeration systems are versatile and can be used in a wide range of applications, from residential air conditioning to commercial and industrial cooling.

Disadvantages of Vapor Compression Refrigeration Systems

Environmental Impact

Some refrigerants used in these systems can have a negative impact on the environment, contributing to global warming and ozone depletion. However, newer, more eco-friendly refrigerants are being developed and used in modern systems.

Maintenance Requirements

Vapor compression refrigeration systems require regular maintenance to ensure their efficiency and longevity. This can include cleaning the coils, checking refrigerant levels, and inspecting other components for wear and tear.

Limited Cooling Capacity

While vapor compression systems are scalable, they do have limits to their cooling capacity. Extremely large or complex cooling needs may require alternative solutions, like absorption or centrifugal chillers.

Vapor Compression Refrigeration Systems vs. Other Refrigeration Methods

Now let’s compare vapor compression refrigeration systems to some alternative cooling methods.

Vapor Compression Versus Absorption Refrigeration

Absorption refrigeration systems use heat instead of mechanical compression to drive the refrigeration cycle. They’re often used in industrial or commercial applications where waste heat is readily available. While these systems can be more environmentally friendly, they’re typically less efficient and more expensive to install and maintain compared to vapor compression systems.

Vapor Compression Versus Air Refrigeration

Air refrigeration systems use air as the refrigerant, compressing and expanding it to achieve cooling. These systems are generally less efficient and have a lower cooling capacity compared to vapor compression systems. However, they can be useful in specific applications where low temperatures or unique environmental conditions are required.

Vapor Compression Versus Thermoelectric Refrigeration

Thermoelectric refrigeration systems use the Peltier effect to create a temperature difference across a solid-state device, which transfers heat from one side to the other. These systems are compact, quiet, and have no moving parts, making them ideal for small-scale cooling applications. However, they’re less energy-efficient and have a limited cooling capacity compared to vapor compression systems.

Conclusion

Summary of Vapor Compression Refrigeration Systems

Vapor compression refrigeration systems are the go-to choice for keeping our homes and businesses cool and comfortable. They’re versatile, energy-efficient, and scalable, making them a great option for a wide range of applications. However, they do come with some drawbacks, like environmental impact and maintenance requirements.

Future Developments in Vapor Compression Refrigeration Technology

As technology continues to advance, we can expect to see even more improvements in vapor compression refrigeration systems. This could include the development of more eco-friendly refrigerants, increased efficiency, and smarter controls that can optimize system performance. So, the future of keeping cool is looking bright!