Here we are, embarking on a journey through the fascinating world of 2-stage refrigeration compressors. You might be thinking, “What’s so fascinating about that?” Well, these machines are the heart of many cooling systems and have some amazing advantages. And, this article is all about unpacking those benefits for you.

Table of Contents

Understanding the Basics of a Refrigeration System

Before we leap into the mechanics of a 2-stage refrigeration compressor, it’s essential to grasp the foundations of a refrigeration system. Buckle up as we explore the building blocks of these fascinating machines.

The role of compressors in refrigeration

A refrigerator is like a small world, where the compressor plays the role of the sun, giving life to everything within. It’s the main engine that drives the refrigeration cycle, making the cool breeze possible. Kinda cool, right?

The concept of refrigeration stages

Now, you might ask, “What’s this business about stages in refrigeration?” Well, think of it like gears in a car. Just as changing gears help a car run smoothly at different speeds, refrigeration stages enable efficient operation under varying cooling loads. A compressor can be single-stage or multi-stage, depending on the number of ‘gears’ it has.

Definition and Explanation of Single-Stage Refrigeration

A single-stage refrigeration system is like a one-speed bike. It’s perfect for cruising along flat roads but struggles with hills. It has one level of compression, which works well for smaller applications that don’t require intense cooling.

Definition and Explanation of Multi-Stage Refrigeration

On the other hand, multi-stage refrigeration is like a bike with multiple gears. It’s equipped to handle more varied and intense cooling requirements. A 2-stage refrigeration compressor, as we’ll discuss further, is a type of multi-stage system.

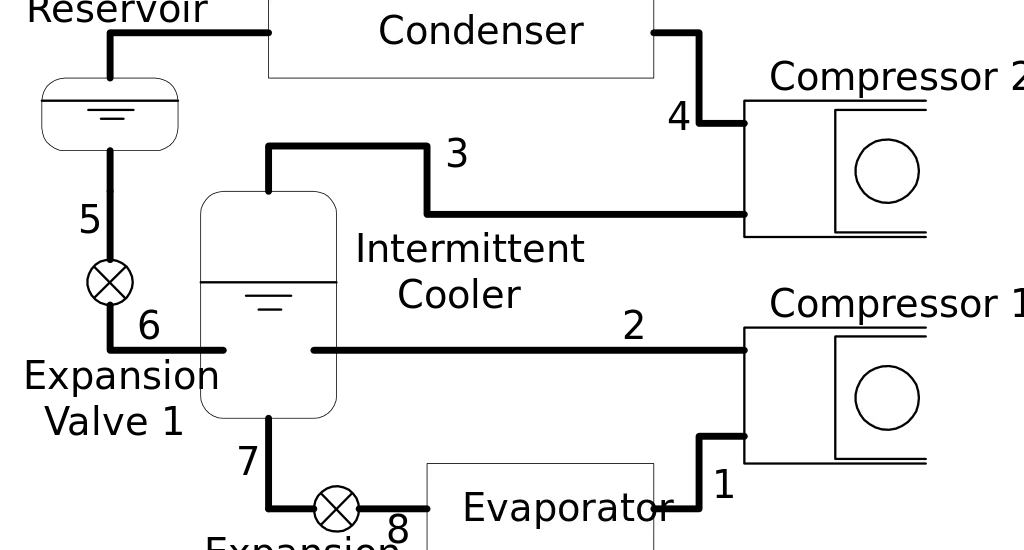

Components involved in the 2-stage refrigeration process

The 2-stage compressor system has a lineup of components each doing their bit to keep things chill. These include two compressor stages, an intercooler for the cooling intermission, and a condenser and evaporator to carry the refrigerant.

Working Principle of a 2-Stage Refrigeration Compressor

Now that we’ve got the basics down, let’s venture into the core of this article – the inner workings of a 2-stage refrigeration compressor. It’s time to unravel the magic that happens within these high-efficiency devices.

Explanation of the 2-stage refrigeration cycle

A 2-stage refrigeration cycle is like a relay race, where the baton (or in this case, the refrigerant) is passed between two runners (the compressor stages). The refrigerant is compressed, cooled, and then compressed again to provide efficient cooling.

The role of the two stages in the cycle

Each ‘runner’ in our relay race plays a crucial role. The first stage starts the process, compressing the refrigerant. The second stage takes over after an intermission for cooling, giving the refrigerant its final squeeze before it heads off to the condenser.

Heat and pressure transformation in each stage

Imagine the refrigerant is like dough. The first stage compressor kneads it, raising its pressure and temperature. It’s kind of like prepping the dough before baking. Then comes an intermission, the intercooler, which cools it down, akin to letting the dough rest.

The second stage gives it one final knead, increasing its pressure and temperature even further. Now, the refrigerant, all set and ready, heads off to the condenser where it dissipates its heat. This whole process is akin to baking the perfect bread: careful preparation, a resting period, and a final bake-off result in a delectable outcome – in our case, optimal cooling.

A detailed walkthrough of the 2-stage compression process

Now let’s take a slow-motion walk through the 2-stage compression process. It’s a symphony of pressure changes and temperature transformations that make your cold drink possible on a hot day.

Intake of refrigerant in the first stage

Picture a low-pressure, low-temperature refrigerant meandering its way into the first-stage compressor. It’s about to go on quite a ride.

Intermediate cooling process

After the first compression, our refrigerant needs a little cool-down, a halftime break if you will. This occurs in the intercooler where it sheds some heat before getting ready for the second round.

Second-stage compression and discharge

Revitalized after its halftime break, the refrigerant enters the second-stage compressor. It’s compressed again and discharged, now super hot and high-pressure, off to the condenser to release all that captured heat.

Benefits of a 2-Stage Refrigeration Compressor

Why all this fuss about 2-stage compressors? Why not just stick with the simple, old single-stage? Well, the 2-stage refrigeration compressor is kind of like the smartphone to the single-stage’s rotary dial phone. It has some seriously cool benefits.

Energy efficiency and performance improvements

One of the most compelling reasons to opt for a 2-stage compressor is its efficiency. You know how driving at a steady speed can save gas? Well, a 2-stage compressor can operate more efficiently under varied cooling loads, saving energy and reducing operational costs.

Enhanced cooling capacity and temperature control

Who wouldn’t want a refrigerator that chills your beverages just right? A 2-stage compressor offers superior temperature control, providing consistent cooling. It’s like having a personal bartender who knows just how you like your drink.

Reduction in wear and tear of the compressor

Imagine a runner who always sprints at full speed versus one who adjusts their pace to the race. Who do you think will last longer? A 2-stage compressor can ‘pace itself’, reducing wear and tear and extending its lifespan.

Noise reduction and operational stability

A 2-stage compressor isn’t just good for your electric bill and your fridge’s longevity; it’s also easier on your ears. Thanks to the intermediate cooling step, these compressors can operate more quietly. So no more eerie fridge noises in the middle of the night!

Check out these other related articles…

Refrigeration Compressor Tripping Breaker: 4 Sure Solutions

Refrigeration Compressor Capacity: A Practical Guide

Refrigeration Compressor Valves: Comprehensive 411 Guide

Refrigeration Compressor Horsepower: The Ultimate 411

Refrigeration Compressor Lube Oil Properties: Expert Guide

Applications of 2-Stage Refrigeration Compressors

Now that we’ve seen the benefits, you might be wondering where these 2-stage compressors are used. Truth is, they’re all around us, working hard in various fields.

Use in industrial refrigeration and air conditioning systems

These hardworking compressors are the backbone of many large-scale refrigeration and air conditioning systems. If you’re enjoying a cool breeze in a shopping mall or working in a temperature-controlled factory, you likely have a 2-stage compressor to thank.

Importance in cold storage and food processing industries

Cold storage and food processing industries are like the ‘never-ending winter’ for food products, and 2-stage compressors play a big part in maintaining those sub-zero conditions. So, next time you enjoy some frozen berries, think of the 2-stage compressors that kept them fresh!

Relevance in scientific and research facilities

It’s not just food and comfort that these compressors help with. They’re also crucial in scientific and research facilities where precise temperature control can make or break an experiment. Yes, even science owes a debt to the 2-stage compressor.

Maintenance and Troubleshooting of a 2-Stage Refrigeration Compressor

Just like any machine, a 2-stage compressor needs a little TLC to keep running smoothly. Let’s take a quick look at what it takes to maintain these mechanical wonders and how to troubleshoot them when things go south.

Key considerations for the routine maintenance of a 2-stage compressor

Maintaining a 2-stage compressor isn’t rocket science. Regular checks on the components, ensuring clean and well-lubricated parts, and checking the refrigerant levels can go a long way in keeping it in top form.

Common problems and troubleshooting steps

Even the best machines have their off days, and 2-stage compressors are no exception. Here’s a heads-up on some common issues and how to troubleshoot them.

Signs of compressor malfunction

If your fridge is behaving like a sulky teenager, not cooling properly, or making strange noises, it might be signaling a compressor issue. And just like with teenagers, it’s crucial to figure out what’s wrong and fix it.

Steps to troubleshoot common issues

When trouble comes knocking, don’t panic. First, check for the easy fixes: power supply issues, blocked vents, or thermostat settings. If the problem persists, it’s likely time to call in the pros. After all, a 2-stage compressor is a sophisticated machine, and some issues are best left to the experts.