Absorption chiller maintenance is key to optimizing the performance and longevity of these eco-friendly cooling systems. In this guide, we’ll explore essential practices, inspections, and troubleshooting tips to ensure smooth operation and prevent unexpected downtime.

Table of Contents

Types of Absorption Chillers

Single-effect Absorption Chiller

These are the simplest and most common type of absorption chillers. They use a single heat source and are known for being relatively low maintenance.

Double-effect Absorption Chiller

Double-effect chillers use two heat sources, making them more efficient but also more complex. This means they need a little extra TLC when it comes to maintenance.

Triple-effect Absorption Chiller

As you might’ve guessed, triple-effect chillers use three heat sources. They’re the most efficient but also have the most maintenance needs. Are you seeing a pattern here?

Differences in Maintenance Requirements based on Type

Each type of chiller has different maintenance needs, so it’s crucial to know what you’re working with. Remember, knowledge is power!

Pre-maintenance Preparations

Safety Precautions

Personal Protective Equipment (PPE)

Before you even think about maintenance, gear up with proper PPE like gloves, goggles, and a hard hat. Safety first!

Lockout/tagout Procedures

Ensure all energy sources are locked and tagged out before starting maintenance. Don’t play with fire (or electricity)!

Read our other articles on absorption refrigeration – Absorption Refrigeration: Easy Guide to Understanding It

Documentation and Record-keeping

Maintenance Log

Keep a log of all maintenance activities. Trust us, you’ll be grateful for those records later on.

Manufacturer’s Guidelines

Always follow the manufacturer’s guidelines for maintenance. They know their stuff, after all.

Tools and Equipment Required

Gather all necessary tools and equipment before you start. Preparation is key!

Scheduling and Notification

Plan maintenance ahead of time and inform relevant parties. No one likes surprises!

Absorption Chiller Maintenance Procedures

Visual Inspection

Checking for Leaks

Inspect the chiller for any leaks. A leaky chiller is like a leaky boat – it won’t get you very far!

Inspecting Components for Wear and Damage

Check all components for signs of wear or damage. A stitch in time saves nine, as they say.

Assessing Insulation

Take a good look at the insulation to make sure it’s in tip-top shape. Good insulation = efficient chiller.

Cleaning

Heat Exchanger Tubes

Clean those heat exchanger tubes to ensure optimal heat transfer. You don’t want a dirty chiller, do you?

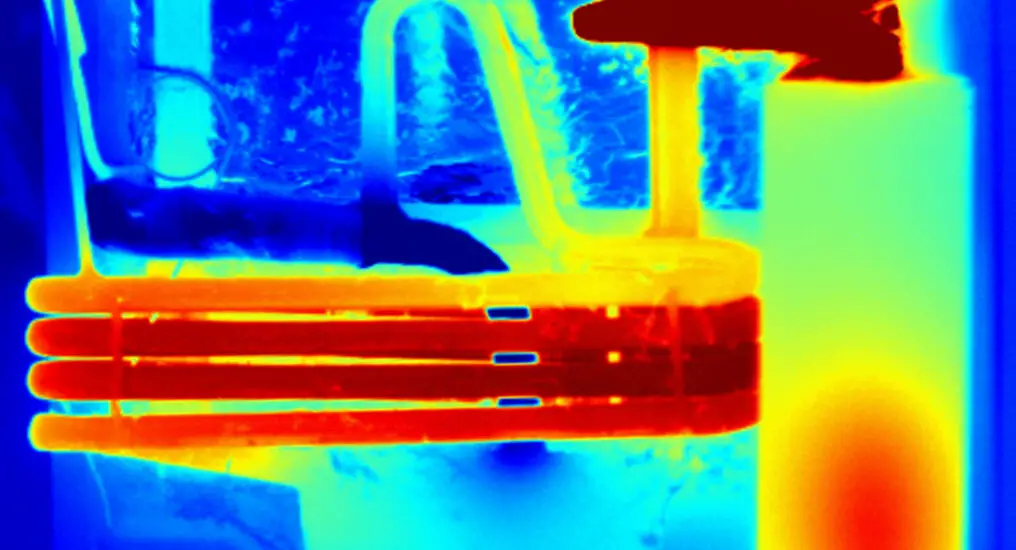

Condenser and Evaporator Coils

Give the condenser and evaporator coils a good scrub. A clean chiller is a happy chiller!

Absorber and Generator Surfaces

Wipe down the absorber and generator surfaces to keep them shiny and efficient. Cleanliness is next to godliness, right?

Lubrication

Pumps and Motors

Don’t forget to lubricate those pumps and motors. They’re the lifeblood of your chiller, after all.

Bearings and Couplings

Lubricate bearings and couplings to keep things running smoothly. Who doesn’t love a well-oiled machine?

Proper Lubricant Selection

Choose the right lubricant for the job. It’s like picking the right wine for dinner – it makes all the difference!

Electrical and Control System Checks

Checking and Tightening Electrical Connections

Inspect and tighten any loose electrical connections. A tight connection is a happy connection!

Verifying Control Settings

Double-check those control settings to make sure they’re spot on. No one wants a chiller gone rogue!

Testing Safety and Operational Switches

Test all safety and operational switches to ensure they’re working correctly. Safety first, folks!

Refrigerant and Absorbent Levels

Checking for Proper Levels

Make sure refrigerant and absorbent levels are just right. It’s all about balance!

Adjusting or Replacing as Needed

If levels are off, adjust or replace as necessary. Better safe than sorry!

Ensuring Proper Refrigerant and Absorbent Quality

Check the quality of your refrigerant and absorbent. Only the best will do!

Performance Monitoring

Measuring Temperature and Pressure

Monitor temperature and pressure levels to keep things running smoothly. You’re the chiller’s personal trainer!

Analyzing System Efficiency

Analyze system efficiency and identify any areas for improvement. A well-tuned chiller is a thing of beauty!

Identifying Areas for Improvement

Take note of any areas that could use a little extra love. Continuous improvement is the name of the game!

Troubleshooting Common Issues

Decreased System Efficiency

Potential Causes

Look for potential causes of decreased efficiency, like leaks, dirty components, or incorrect settings. A little detective work goes a long way!

Solutions and Adjustments

Once you’ve identified the issue, make the necessary adjustments or repairs. Problem-solving at its finest!

Noisy Operation

Identifying Sources of Noise

Pinpoint the source of any strange noises. Your chiller shouldn’t sound like a rock concert!

Addressing and Mitigating Noise Issues

Address and mitigate any noise issues you find. Peace and quiet, here we come!

Leaks

Locating and Repairing Leaks

Find and fix any leaks ASAP. Remember, a leaky chiller is a sad chiller! If you need to, contact a licensed technician.

Preventing Future Leaks

Take steps to prevent future leaks, like proper maintenance and inspections. An ounce of prevention is worth a pound of cure!

Post-maintenance Procedures

System Restart

Ensuring all Components are Reconnected

Before restarting your chiller, double-check that all components are reconnected. Better safe than sorry!

Following Proper Startup Procedures

Follow the manufacturer’s startup procedures to get your chiller up and running again. You’ve got this!

Documentation and Record-keeping

Updating Maintenance Log

Update your maintenance log with all the work you’ve done. Your future self will thank you!

Recording any Adjustments or Repairs Made

Document any adjustments or repairs you made during maintenance. Knowledge is power, after all.

Communicating Results to Stakeholders

Notifying Relevant Personnel

Notify any relevant personnel about the completed maintenance. Communication is key!

Reporting any Ongoing or Unresolved Issues

Report any ongoing or unresolved issues to the appropriate parties. You’re not in this alone!

Preventative Maintenance Program

Importance of Preventative Maintenance

Preventative maintenance is crucial to keep your chiller running at peak performance. It’s like getting regular checkups at the doctor!

Developing a Maintenance Schedule

Create a maintenance schedule that works for you and your chiller. Consistency is key!

Training and Education for Maintenance Staff

Ensure maintenance staff are well-trained and educated in chiller maintenance. Knowledgeable staff = well-maintained chiller!

Conclusion

So there you have it – all the ins and outs of absorption chiller maintenance. Remember, regular maintenance is essential for optimal chiller performance. Keep your chiller in top shape, and it’ll keep you cool and comfortable in return. Happy chilling!