Charging 410A by subcooling is a crucial part of maintaining your home’s HVAC system. It helps ensure that your air conditioning runs smoothly and efficiently, keeping your home cool and comfortable. But what exactly is subcooling, and why is it so important? In this guide, we’ll break down everything you need to know about subcooling and how to charge your 410A refrigerant system correctly. So let’s dive in, shall we?

Table of Contents

Purpose of Subcooling

Importance of Proper Refrigerant Charge

A proper refrigerant charge is essential for your HVAC system to function efficiently. When the refrigerant charge is incorrect, it can lead to increased energy consumption, reduced cooling capacity, and even damage to your equipment. Subcooling is one of the methods used to ensure that your system has the correct amount of refrigerant, keeping everything running smoothly and avoiding costly repairs.

Subcooling vs. Superheat

Subcooling and superheat are two different methods for determining the correct refrigerant charge. Subcooling focuses on the liquid refrigerant in the condenser, while superheat deals with the vapor refrigerant in the evaporator. Both methods are important, but subcooling is the preferred method for charging 410A systems as it provides more accurate and reliable results.

Overview of 410A Refrigerant

Properties and Benefits

410A refrigerant, also known as R-410A, is a popular choice for residential air conditioning systems. It’s an environmentally friendly alternative to older refrigerants like R-22, with a significantly lower ozone depletion potential. Additionally, 410A systems typically have higher energy efficiency and better cooling performance than their R-22 counterparts.

Safety Precautions

When working with 410A refrigerant, it’s important to follow safety precautions. This includes wearing appropriate personal protective equipment (PPE), such as gloves and safety goggles, and ensuring proper ventilation in the workspace. Remember that refrigerants can be hazardous if not handled correctly, so always follow the manufacturer’s guidelines and safety recommendations.

Tools and Equipment

Necessary Tools

HVAC Gauges

An essential tool for charging 410A by subcooling is a set of HVAC gauges. These gauges allow you to measure the pressure in your system, helping you determine the correct refrigerant charge. Make sure to use gauges specifically designed for use with 410A refrigerant.

Temperature Probe or Infrared Thermometer

A temperature probe or infrared thermometer is used to measure the temperature of the refrigerant lines. Accurate temperature measurements are critical for calculating subcooling and ensuring the proper refrigerant charge.

Refrigerant Scale

A refrigerant scale is necessary for weighing the refrigerant you add to or remove from the system. It helps ensure you add the correct amount of refrigerant based on your subcooling calculations.

410A Refrigerant Cylinder

Of course, you’ll need a 410A refrigerant cylinder to recharge your system. Make sure to use only approved refrigerant cylinders to avoid any potential hazards or contamination.

Optional Tools

Electronic Leak Detector

An electronic leak detector can be useful for identifying any refrigerant leaks in your system before you start charging. Detecting and repairing leaks is essential for maintaining the efficiency and performance of your HVAC system.

Vacuum Pump

A vacuum pump can be used to remove any air or moisture from the system before charging. While not always necessary, using a vacuum pump can help ensure optimal system performance.

Recovery Machine

A recovery machine is used to remove refrigerant from the system before servicing or charging. This is an optional tool but can be helpful for maintaining a clean and safe workspace.

Preparing for the Charging Process

Safety Considerations

Personal Protective Equipment (PPE)

Before starting the charging process, ensure you’re wearing the appropriate PPE, such as safety goggles and gloves. This will help protect you from potential hazards associated with handling refrigerants.

Handling Refrigerants Safely

Always follow the manufacturer’s guidelines and safety recommendations when handling refrigerants. This includes proper ventilation, storage, and disposal of refrigerant cylinders. Remember that refrigerants can be hazardous if not handled correctly.

Identifying System Requirements

Manufacturer’s Guidelines

Consult your HVAC system’s manufacturer guidelines for specific information on charging 410A by subcooling. This may include the target subcooling and any other necessary instructions. Following the manufacturer’s guidelines will help ensure the best performance and longevity of your system.

Subcooling Target Range

Determine the target subcooling range for your specific system. This information can typically be found in the manufacturer’s guidelines or on the unit’s data plate. The target range may vary depending on your system and climate, so it’s crucial to identify the correct range for your specific needs.

Charging Procedure

Step 1 – System Setup

Power Off the HVAC Unit

Before starting the charging process, ensure the HVAC unit is powered off. This will help ensure your safety and prevent any damage to the system while you’re working.

Connect HVAC Gauges

Connect your HVAC gauges to the appropriate ports on your system. Be sure to use gauges specifically designed for 410A refrigerant, and follow the manufacturer’s instructions for proper connection.

Position Temperature Probe

Place your temperature probe or infrared thermometer on the suction line (larger refrigerant line) near the evaporator coil. This will allow you to measure the suction line temperature during the charging process.

Step 2 – Taking Measurements

Measure Suction Line Temperature

With your temperature probe in place, measure the suction line temperature. This measurement will be used to calculate subcooling later in the process.

Measure Liquid Line Temperature

Measure the temperature of the liquid line (smaller refrigerant line) near the condenser unit. This measurement is also necessary for calculating subcooling.

Measure High-side Pressure

Using your HVAC gauges, measure the high-side pressure in your system. This pressure reading will be used to determine the corresponding saturation temperature of the refrigerant.

Step 3 – Calculating Subcooling

Convert High-side Pressure to Temperature

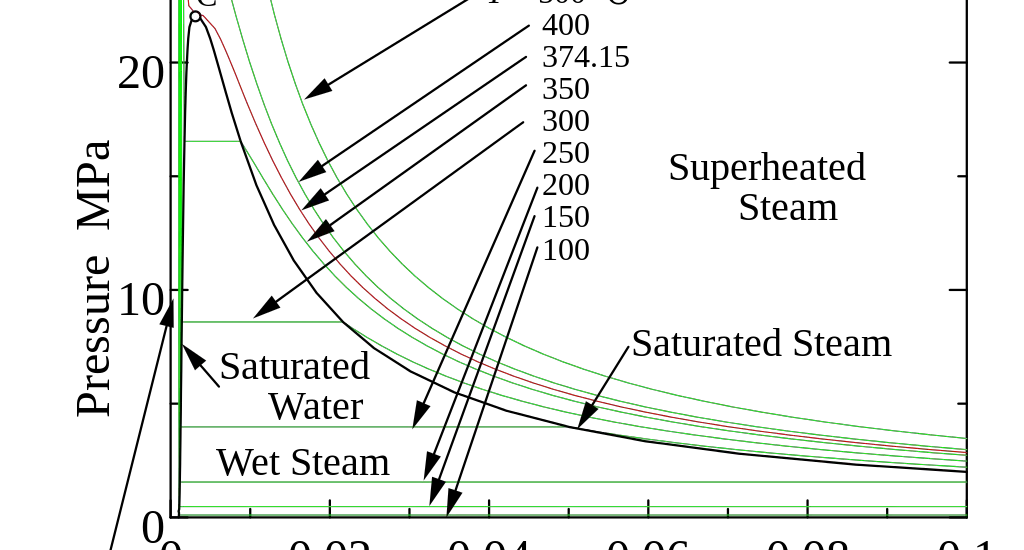

Refer to a 410A pressure-temperature chart or use an HVAC app to convert the high-side pressure reading to the corresponding saturation temperature.

Determine Current Subcooling

Subtract the liquid line temperature from the saturation temperature. This value represents your system’s current subcooling.

Compare with Target Subcooling

Compare your calculated subcooling value with the target subcooling range for your system. If the value falls within the target range, no further action is necessary. If the value is outside the target range, proceed to Step 4.

Step 4 – Charging the System

Adjust Refrigerant Charge

If your subcooling value is outside the target range, adjust the refrigerant charge as necessary. If subcooling is too low, add refrigerant; if subcooling is too high, remove refrigerant. Use a refrigerant scale to ensure accurate charging.

Monitor Subcooling

As you adjust the refrigerant charge, continue to monitor the subcooling value. This will help you determine when the correct charge has been achieved.

Stabilize and Recheck Measurements

Once the target subcooling range has been reached, allow the system to stabilize for several minutes. Then, recheck your measurements to ensure everything is still within the target range and that the system is operating efficiently.

Finishing Up

Disconnecting Tools and Equipment

Safely Vent Remaining Refrigerant

When you’ve finished charging the system, safely vent any remaining refrigerant in the hoses according to the manufacturer’s instructions and local regulations.

Remove Gauges and Temperature Probe

Disconnect the HVAC gauges and remove the temperature probe from the refrigerant lines. Be sure to store your tools properly to prevent damage or contamination.

Power On the HVAC Unit

With everything disconnected and properly stored, power on your HVAC unit and allow it to run for a few minutes. This will help you confirm that the system is functioning correctly after the charging process.

Documenting the Process

Record Final Measurements

It’s essential to document the final measurements and adjustments you made during the charging process. This information can be helpful for future maintenance or troubleshooting.

Note Any Adjustments or Repairs

If you made any adjustments or repairs during the charging process, document these as well. This information can be valuable for ensuring the ongoing performance and efficiency of your HVAC system.

Troubleshooting Common Issues

Insufficient Subcooling

Causes and Solutions

Insufficient subcooling can be caused by a variety of factors, such as low refrigerant charge, restrictions in the refrigerant lines, or dirty condenser coils. To address this issue, check for refrigerant leaks, clean the condenser coils, and ensure there are no restrictions in the refrigerant lines.

Excessive Subcooling

Causes and Solutions

Excessive subcooling can be caused by an overcharged system, a malfunctioning expansion valve, or inadequate airflow across the evaporator coil. To resolve this issue, verify the refrigerant charge, inspect the expansion valve, and ensure proper airflow across the evaporator coil.

Other HVAC Performance Issues

Leaks

Refrigerant leaks can lead to a variety of performance issues and should be addressed promptly. Use an electronic leak detector to locate and repair any leaks in your system.

Dirty or Restricted Components

Dirty or restricted components can reduce the efficiency and performance of your HVAC system. Regularly clean and inspect your system’s components, such as the air filter, evaporator coil, and condenser coil, to ensure optimal performance.

Mechanical Failures

Mechanical failures can cause a variety of issues with your HVAC system. If you suspect a mechanical failure, consult a professional technician for assistance.

Conclusion

Importance of Proper Charging

Properly charging your HVAC system by subcooling is essential for maintaining its efficiency and performance. By following the steps outlined in this guide, you can ensure your 410A system is charged correctly and operates smoothly for years to come.

Maintenance and Ongoing Monitoring

Regular Inspections

Regular inspections and maintenance can help identify potential issues before they become significant problems. Schedule routine checkups to keep your system in peak condition.

Addressing Performance Issues Promptly

If you notice any performance issues with your HVAC system, address them promptly to prevent further complications. This includes addressing refrigerant leaks, cleaning dirty components, and troubleshooting any mechanical failures.

By following the advice and procedures outlined in this article, homeowners can confidently charge their 410A systems by subcooling, ensuring optimal performance and energy efficiency. Proper maintenance and ongoing monitoring will keep your HVAC system running smoothly and help you stay comfortable in your home.