Coil heat exchangers are a game-changer in the world of heat transfer systems. What’s their secret, you ask? Let’s dive in and unravel the mysteries together!

Table of Contents

Definition and Purpose

So, what exactly is a coil heat exchanger? In simple terms, it’s a device that transfers heat between two fluids without mixing them. Why is that important? Well, they play a crucial role in industries like HVAC, power generation, and chemical processing, just to name a few.

Coil Heat Exchanger Definition

A coil heat exchanger consists of a series of coiled tubes, through which fluids flow and exchange heat. Sounds simple, right? But don’t let its simplicity fool you – it’s a highly efficient heat transfer solution!

Primary Functions and Applications

From air conditioning to chemical plants, coil heat exchangers are everywhere! They’re used for cooling, heating, and even recovering waste heat. Can you imagine a world without them? We’d be drowning in wasted energy!

Types of Coil Heat Exchangers

Did you know there are different types of coil heat exchangers? Let’s take a closer look at these unsung heroes of heat transfer.

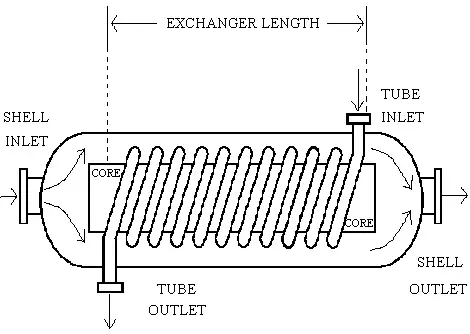

Shell and Coil Heat Exchangers

Imagine a snail’s shell, but filled with coiled tubes. That’s a shell and coil heat exchanger for you! They’re known for their compact design and high heat transfer efficiency.

Helical Coil Heat Exchangers

Picture a spiral staircase, with each step representing a coil. That’s the essence of a helical coil heat exchanger. These bad boys are great for high-pressure applications and excel in thermal performance.

Double Pipe Coil Heat Exchangers

Ever played with nesting dolls? That’s the idea behind double pipe coil heat exchangers. One pipe is nestled inside another, allowing heat to transfer between fluids. Simple yet effective!

Spiral Heat Exchangers

Think of two metal sheets rolled up like a cinnamon roll. That’s a spiral heat exchanger. Their unique design makes them a top choice for handling fouling fluids and high-pressure situations.

Components of Coil Heat Exchangers

Let’s take a peek under the hood and see what makes coil heat exchangers tick.

Tubes

Those coiled tubes are the heart and soul of a coil heat exchanger. But not all tubes are created equal – material selection and tube shape matter!

Material Selection

Stainless steel, copper, or maybe even titanium? The right material depends on the application, fluid compatibility, and operating conditions. It’s like choosing the perfect outfit for a night out!

Tube Shape and Configuration

Straight, U-shaped, or maybe even spiral? Tube shape and configuration play a big role in heat transfer efficiency. It’s like picking the right dance partner – you want someone who can keep up with you!

Shell

The shell is like the sturdy armor that protects those precious tubes. Let’s see what goes into choosing the right material and design.

Material Selection

From carbon steel to high-alloy materials, the shell material should be able to withstand the operating conditions and resist corrosion. Remember, a strong shell is a happy shell!

Shell Design and Construction

The shell’s design should allow for optimal flow distribution and provide easy access for maintenance. It’s like designing a house – you want it to be both functional and inviting!

Baffles

These unsung heroes direct the fluid flow to maximize heat transfer. Let’s give them some love!

Function and Types

Baffles come in different shapes and sizes, but they all serve the same purpose – to improve heat transfer efficiency. Think of them as the traffic directors of fluid flow!

Material and Design Considerations

Baffle material should be compatible with the fluids and resistant to corrosion. As for design, it should allow for even distribution of fluid and minimize pressure drop. A well-designed baffle is like a skilled conductor, orchestrating a symphony of heat transfer!

Headers and Nozzles

These are the gatekeepers of fluid flow. Let’s explore their role in the coil heat exchanger ensemble.

Function and Design

Headers and nozzles control the flow of fluids in and out of the heat exchanger. Their design should minimize pressure drop and ensure even distribution. It’s like finding the perfect faucet for your sink – it needs to be both efficient and stylish!

Material Selection and Construction

Just like the other components, header and nozzle materials should be compatible with the fluids and able to withstand operating conditions. They need to be strong and durable – after all, they’re the guardians of fluid flow!

Working Principle of Coil Heat Exchangers

Now that we know what’s inside a coil heat exchanger, let’s see how it all works together to transfer heat efficiently.

Heat Transfer Mechanisms

There are three main ways heat can be transferred: conduction, convection, and radiation. Which one(s) do you think coil heat exchangers use?

Conduction

Conduction is the transfer of heat through solid objects. In coil heat exchangers, it occurs when heat moves through the tube walls. It’s like holding a hot cup of coffee – you can feel the heat travel through the cup and warm your hands!

Convection

Convection is the transfer of heat through fluids. In coil heat exchangers, it happens when the fluids move over the tubes and exchange heat. It’s like the warm breeze you feel on a summer day!

Radiation

Radiation is the transfer of heat through electromagnetic waves. While it’s not a significant player in coil heat exchangers, it’s still good to know. After all, it’s what makes the sun feel warm on your skin!

Flow Arrangements

There are three main flow arrangements in coil heat exchangers: parallel flow, counter flow, and cross flow. Let’s take a closer look at each one.

Parallel Flow

Counter Flow

In counter flow, the fluids move in opposite directions. This setup is more efficient for heat transfer because it maintains a greater temperature difference between the fluids. It’s like walking past someone on the street – you briefly exchange glances and then carry on in opposite directions!

Cross Flow

In cross flow, the fluids move perpendicular to each other. This arrangement is a bit of a compromise between parallel and counter flow, offering a balance between efficiency and pressure drop. It’s like crossing paths with someone at an intersection – you briefly interact, but then go your separate ways!

Performance and Efficiency

Now that we understand how coil heat exchangers work, let’s see what factors affect their performance and how we can improve their efficiency.

Factors Affecting Performance

There are several factors that can impact a coil heat exchanger’s performance, such as fluid properties, surface area, and fouling. Let’s explore each of these in more detail.

Fluid Properties

The properties of the fluids, like viscosity and specific heat, can influence heat transfer efficiency. It’s like trying to run through water versus air – the thicker the fluid, the more resistance you’ll encounter!

Surface Area and Heat Transfer Coefficient

A larger surface area and higher heat transfer coefficient mean more efficient heat exchange. It’s like the difference between a small towel and a large one – the larger towel can absorb more water!

Fouling and Corrosion

Over time, fouling and corrosion can reduce a coil heat exchanger’s efficiency. It’s like dirt and rust accumulating on your car – not only does it look bad, but it can also hinder performance!

Methods to Improve Efficiency

So, how can we make coil heat exchangers even more efficient? Here are some strategies to consider:

Optimal Design and Material Selection

Choosing the right materials and design for the specific application can greatly improve efficiency. It’s like selecting the perfect pair of shoes for a long hike – you need the right fit and support!

Enhanced Heat Transfer Surfaces

By using surfaces with specialized geometries or coatings, we can increase the heat transfer rate. It’s like adding extra layers of insulation to your home – it helps keep the heat in (or out) more effectively!

Flow Optimization and Control

Adjusting the flow rate and direction can also enhance heat transfer efficiency. It’s like adjusting the speed and direction of a fan – you want the airflow to be just right for optimal cooling!