Ever wondered how your fridge stays cool? It’s all about heat transfer, folks! Let’s explore the basics and dive deep into how heat transfer in refrigeration systems works to keep your food fresh and your drinks cold. Buckle up, it’s gonna be a wild ride!

Table of Contents

Basic principles of heat transfer in refrigeration systems

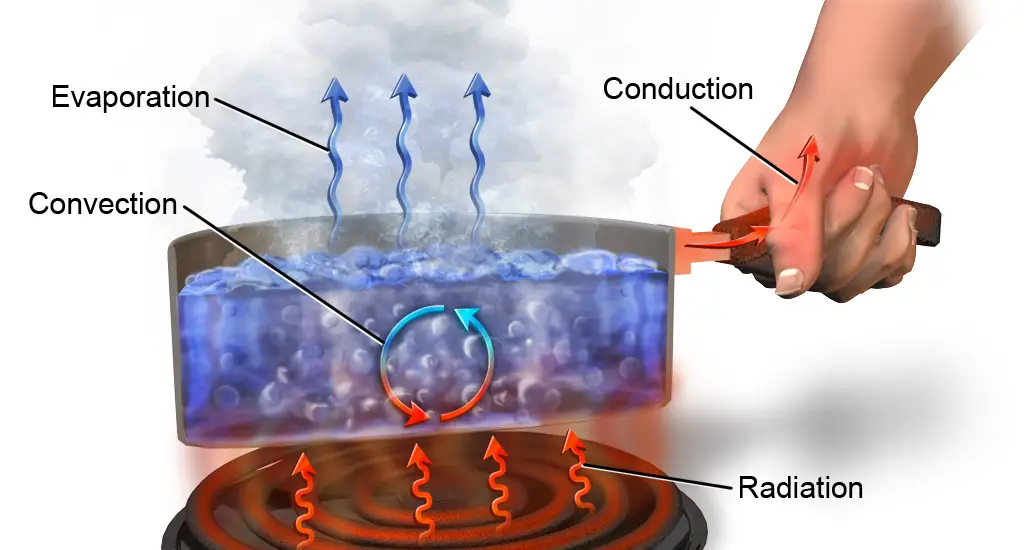

Heat transfer is the heart and soul of refrigeration systems. Three key players make this happen: conduction, convection, and radiation. Ready to meet them?

Conduction

Conduction’s the silent hero, passing heat through solid objects. Think of it like a gossip chain, with heat spreading from one molecule to another. The hotter it gets, the more they talk!

Convection

Convection’s the life of the party! It moves heat through fluids (like air and water), creating currents that whisk heat away. Whoosh! Goodbye, heat!

Radiation

Radiation’s a bit of a show-off, sending heat through empty space. No need for direct contact, it’s just like magic!

Refrigeration system components

Now that you know the basics, let’s meet the all-star cast that makes refrigeration systems work: compressor, condenser, expansion device, and evaporator. Each one plays a key role in managing heat transfer. Time for the big reveal!

Compressor

The compressor’s like a bouncer, squeezing refrigerant gas and forcing it to move through the system. It’s all about keeping the party going!

Condenser

The condenser’s a smooth operator, cooling down the hot refrigerant and turning it into a liquid. One word: chill.

Expansion device

The expansion device’s a bit of a control freak, regulating the flow of refrigerant to the evaporator. It’s all about finding the perfect balance.

Evaporator

The evaporator’s the true star of the show, absorbing heat and turning liquid refrigerant into gas. Presto! Your fridge is cool!

Compressor and Heat Transfer in Refrigeration Systems

Let’s take a closer look at the compressor and how it helps with heat transfer in refrigeration systems. It’s time to dig deeper, folks!

Role of the compressor in heat transfer

Remember the bouncer analogy? The compressor pushes refrigerant gas through the system, working its magic on heat transfer in refrigeration systems. Let’s break it down!

Compression of refrigerant gas

The compressor squeezes refrigerant gas, increasing its pressure and temperature. It’s like when you squeeze a stress ball – the pressure’s on!

Heat generation during compression

As the gas compresses, it generates heat. But don’t worry, the condenser’s got your back, ready to cool things down!

Compressor types and their impact on heat transfer in refrigeration systems

Not all compressors are created equal. Let’s check out the different types and how they affect heat transfer in refrigeration systems. Who’s the real MVP?

Reciprocating compressors

Reciprocating compressors are like a piston engine, with back-and-forth motion. They’re reliable, but can

be a bit noisy. The heat transfer? Pretty solid, but not the most efficient.

Scroll compressors

Scroll compressors are like a dance routine, with two spirals moving together. They’re smooth and efficient, making heat transfer a breeze. Bravo!

Rotary compressors

Rotary compressors spin like a top, using rollers to compress refrigerant gas. They’re compact and quiet, but heat transfer might not be their strong suit.

Centrifugal compressors

Centrifugal compressors are like a merry-go-round, using centrifugal force to compress the gas. They’re efficient and powerful, but can be pricey. When it comes to heat transfer, they’re top-notch!

Condenser and Heat Transfer in Refrigeration Systems

Now, let’s shine the spotlight on the condenser and its role in heat transfer. It’s time for this cool cat to take center stage!

Role of the condenser in heat transfer in refrigeration systems

The condenser’s job is to keep things cool by rejecting heat from the refrigerant. How does it do it? Let’s find out!

Heat rejection from the refrigerant

The condenser takes the heat generated during compression and sends it packing. Sayonara, heat!

High-pressure, high-temperature gas to liquid transformation

The condenser transforms the hot refrigerant gas into a cool liquid, ready for the next stage. It’s like a mini spa day for the refrigerant!

Types of condensers and their impact on heat transfer in refrigeration systems

Condensers come in different flavors, each with its own impact on heat transfer in refrigeration systems. Let’s take a look!

Air-cooled condensers

Air-cooled condensers use air to whisk away heat. They’re simple and effective, but how do they stack up in terms of heat transfer?

Finned tube condensers

Finned tube condensers have fins that increase surface area, making heat transfer a breeze. A fan favorite!

Microchannel condensers

Microchannel condensers have tiny channels for better heat transfer. They’re compact and efficient, but can be a bit finicky to clean.

Water-cooled condensers

Water-cooled condensers use water to do the heavy lifting. They’re great for heat transfer, but can be a bit more complex.

Shell and tube condensers

Shell and tube condensers are like a maze, with refrigerant and water weaving through tubes. They’re reliable and efficient, making heat transfer a cinch!

Plate heat exchanger condensers

Plate heat exchanger condensers use plates for heat transfer. They’re compact and efficient, but can be a bit pricey. Still, they’re top performers when it comes to heat transfer!

Expansion Device and Heat Transfer

Next up: the expansion device! Let’s explore its role in heat transfer and how different types affect the process. Are you ready to expand your knowledge?

Role of the expansion device in heat transfer

The expansion device controls the flow of refrigerant and helps regulate pressure and temperature. Let’s see how it impacts heat transfer!

Pressure and temperature reduction of refrigerant

The expansion device drops the pressure and temperature of the refrigerant, prepping it for the evaporator. It’s like a cool-down session after a workout!

Expansion of liquid refrigerant

The device also expands the liquid refrigerant, spreading it out and getting it ready for some serious heat transfer action in the evaporator.

Types of expansion devices and their impact on heat transfer in refrigeration systems

Expansion devices come in different shapes and sizes. Let’s compare them and see which one’s the heat transfer champ!

Capillary tubes

Capillary tubes are thin and simple, using pressure differences to control refrigerant flow. They’re low-cost and easy to maintain, but not always the most efficient when it comes to heat transfer.

Thermostatic expansion valves (TXVs)

TXVs are like a thermostat for your refrigerant, adjusting the flow based on temperature. They’re more precise, making heat transfer more efficient. Nice!

Electronic expansion valves (EXVs)

EXVs are the high-tech option, using electronic sensors for precise control. They’re efficient and adaptable, making them heat transfer superstars!

Evaporator and Heat Transfer

Finally, let’s meet the evaporator, the star player in the heat transfer game. It’s time to discover its secrets!

Role of the evaporator in heat transfer

The evaporator’s where the magic happens, absorbing heat and transforming the refrigerant. Let’s break down its role in heat transfer!

Heat absorption from the surrounding environment

The evaporator sucks up heat from its surroundings, like a heat-sucking vampire. It’s the key to keeping things cool!

Low-pressure, low-temperature liquid to gas transformation

As the evaporator absorbs heat, the refrigerant changes from a low-pressure liquid to a gas. Ta-da! The heat’s been transferred!

Types of evaporators and their impact on heat transfer in refrigeration systems

Evaporators come in different styles, each with its own heat transfer prowess. Let’s see who’s got the moves!

Direct expansion (DX) evaporators

DX evaporators work directly with the refrigerant, making them simple and effective. How do they fare in terms of heat transfer?

Finned tube evaporators

Finned tube evaporators use those handy fins to boost heat transfer. They’re reliable and efficient, making them a popular choice!

Plate heat exchanger evaporators

Plate heat exchanger evaporators use plates for heat transfer, just like their condenser counterparts. They’re compact and efficient, but can be pricier. Still, they’re heat transfer rock stars!

Flooded evaporators

Flooded evaporators immerse tubes in a pool of refrigerant for maximum heat transfer. They’re efficient, but a bit more complex and costly. If you’re looking for top-notch heat transfer, though, they’re worth considering!

Refrigerant Selection and Heat Transfer

Now that we’ve met the team, let’s talk about the star player: refrigerant. The right refrigerant can make all the difference in heat transfer. Are you ready to find the perfect match?

Characteristics of a good refrigerant

What makes a refrigerant great? It’s all about the right mix of thermodynamic properties, chemical stability, and environmental impact. Let’s dive in!

Thermodynamic properties

A good refrigerant has the right combo of boiling point, heat capacity, and pressure. It’s like finding the perfect dance partner for your heat transfer tango!

Chemical stability

Stability matters, too! A great refrigerant won’t break down or react with other components, ensuring a long and happy life for your refrigeration system.

Environmental impact

Last but not least, a good refrigerant plays nice with the environment. No ozone depletion or global warming here, thank you very much!

Common refrigerants and their impact on heat transfer in refrigeration systems

There are plenty of refrigerants to choose from, each with its own heat transfer properties. Let’s explore some popular options!

Hydrochlorofluorocarbons (HCFCs)

HCFCs, like R-22, were once popular but are now being phased out due to their ozone-depleting ways. Their heat transfer properties were decent, but it’s time to move on!

Hydrofluorocarbons (HFCs)

HFCs, like R-410A and R-134a, are the new kids on the block. They’re ozone-friendly and offer solid heat transfer performance. A great choice for most systems!

Natural refrigerants (ammonia, CO2, hydrocarbons)

Natural refrigerants, like ammonia, CO2, and hydrocarbons (propane, isobutane), are eco-friendly and boast impressive heat transfer properties. They’re gaining popularity and could be the future of refrigeration!

Advanced Techniques for Optimizing Heat Transfer

Want to take your heat transfer game to the next level? Let’s explore some advanced techniques for optimizing performance. Are you ready to go pro?

Enhanced heat transfer surfaces

One way to boost heat transfer is to get fancy with your surfaces. Let’s check out some options!

Microfin tubes

Microfin tubes have tiny fins that increase surface area and enhance heat transfer. They’re like a turbo boost for your refrigeration system!

Corrugated and wavy surfaces

Corrugated and wavy surfaces can also improve heat transfer by disrupting fluid flow and increasing turbulence. It’s like a roller coaster ride for your refrigerant!

Liquid and vapor injection

Another way to optimize heat transfer is to play with liquid and vapor injection. Intrigued? Let’s dive in!

Liquid subcooling

Liquid subcooling cools the refrigerant even more before it hits the expansion device. The result? Better heat transfer and improved efficiency. It’s like an extra chill pill for your refrigerant!

Vapor injection for capacity control

Vapor injection lets you control the compressor’s capacity by injecting vapor at different stages. This clever trick can boost heat transfer and keep your system running smoothly. A win-win!

Heat recovery systems

Finally, let’s talk about heat recovery systems. They’re all about turning waste heat into useful energy. Ready to see how it’s done?

Heat reclaim systems

Heat reclaim systems capture waste heat from the condenser and put it to work, like heating water or warming your home. It’s like recycling for heat transfer!

Desuperheaters

Desuperheaters are another type of heat recovery system that captures waste heat from the compressor. They can improve heat transfer and overall system efficiency. Talk about an energy-saving superstar!

There you have it, folks! Now you’re an expert on heat transfer in refrigeration systems. With this knowledge, you’ll be able to make informed decisions about your home’s cooling needs, keeping things comfortable and energy-efficient. Stay cool, friends!