Are you confused about the role of a condenser vs compressor in an HVAC system? It’s like trying to figure out who does what in a band. The drummer? The bass player? Who’s making that sweet rhythm that keeps everything running? Let’s set things straight.

Table of Contents

Brief Overview of Condensers and Compressors

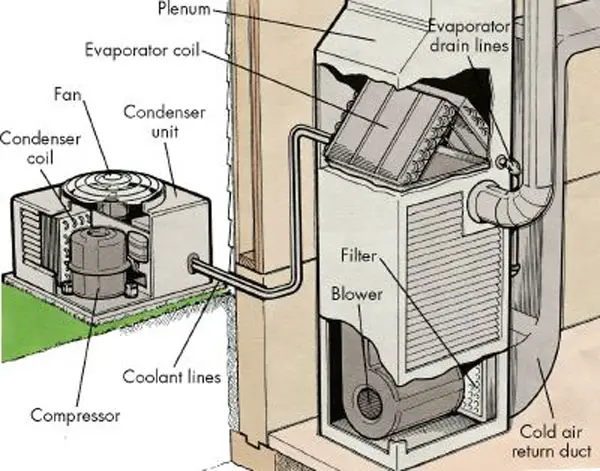

Picture condensers and compressors as the heart and lungs of your HVAC system. They’re the bandmates who create the rhythm and keep the air flowing. In layman’s terms, a compressor squeezes or compresses the refrigerant, transforming it into a high-pressure gas. A condenser, on the other hand, acts like a radiator, dissipating heat and converting that high-pressure gas back into a cooler high-pressure liquid. See? Not that hard, is it?

Understanding Compressors

In this section, we’ll find out more about the compressor, the different types, and its working principle.

What is a Compressor?

Think of a compressor like a tough bouncer at a nightclub. It takes that low-pressure refrigerant and gives it some muscle, turning it into a high-pressure gas. And this isn’t just for show – it’s a crucial step in the cooling process of your HVAC system.

Types of Compressors

Compressors come in various flavors – each with a unique spin on how they pump up the refrigerant. The most common types include reciprocating, rotary, screw, scroll, and centrifugal compressors.

Reciprocating compressors, also known as piston compressors, use pistons driven by a crankshaft to compress the refrigerant.

Rotary compressors use a mechanism involving a roller, cylinder, and a pair of blades to pressurize the refrigerant.

Screw compressors use two meshing screws, whereas scroll compressors utilize two spiral-shaped scroll pieces.

Finally, centrifugal compressors use a rotating impeller to transfer energy to the refrigerant.

Working Principle of Compressors

The working principle of a compressor is relatively straightforward. It starts by drawing in low-pressure refrigerant gas from the evaporator. The compressor then pressurizes this gas, thereby increasing its temperature.

The high-pressure, high-temperature refrigerant gas is then discharged to the condenser for the next phase of the refrigeration cycle. The specific method of compression varies depending on the type of compressor, but the end result is the same.

Understanding Condensers

Now, let’s turn our attention to the condenser.

What is a Condenser?

The condenser is like the cool-down after a hardcore gym session. It takes that high-pressure gas from the compressor and cools it down, transforming it back into a liquid. But it’s not just about cooling; the condenser also releases the heat carried over from the compressor out into the surrounding environment.

Types of Condensers

Condensers, much like compressors, also come in different types – air-cooled, water-cooled, and evaporative.

Air-cooled condensers use surrounding air to cool and condense the refrigerant, while water-cooled condensers use water for the same purpose.

Evaporative condensers, on the other hand, combine the cooling properties of water and air.

These types differ in their cooling efficiency, cost, and suitability for different applications.

Working Principle of Condensers

After the compressor does its job, the high-pressure, high-temperature refrigerant gas flows into the condenser. The condenser then dissipates the heat carried by the refrigerant to the surrounding medium (air or water).

As the refrigerant loses its heat, it cools and condenses back into a high-pressure liquid. This liquid then moves to the expansion valve, ready for another round of cooling in the evaporator.

Check out these other related articles…

What Does a Condenser Do? Comprehensive Answer

Evaporator Coil vs Condenser Coil: Ultimate Comparison

Condenser Coil in Refrigerator: Your Ultimate 411 Guide

Dirty Condenser Coil Symptoms: Comprehensive 411 Guide

Condenser Heat Pump: Your Comprehensive Guide

Condenser vs Compressor: The Key Differences

So, who plays the tune better in this HVAC orchestra, the compressor or the condenser?

Functionality Differences

While both condensers and compressors are integral parts of an HVAC system, they serve different functions. The compressor’s role is to increase the refrigerant’s pressure and temperature, setting the stage for the cooling process.

The condenser, in contrast, releases the heat from the refrigerant, cools it down, and transforms it back into a high-pressure liquid. It’s a continuous relay race between the two, each passing the baton (refrigerant) to the next in the cooling cycle.

Physical Differences

Physically, compressors and condensers have distinct differences. A compressor generally has a motor and pump assembly housed within a sturdy, often cylindrical, casing. It looks robust and durable, ready to handle high pressure.

A condenser, on the other hand, usually looks more like a radiator or a coil, designed for efficient heat exchange. It often comes with a fan to facilitate air movement for better cooling.

Energy Consumption

The energy consumption of a compressor and a condenser depends on their efficiency, the size of the HVAC system, and its overall use. Generally, the compressor, being the primary mover of the refrigerant, tends to consume more energy. However, inefficient or improperly sized condensers can also lead to increased energy usage due to poor heat transfer performance.

Considerations when Choosing Between a Condenser and a Compressor

Choosing the right performer for your HVAC orchestra can be tricky. It’s like choosing between Mozart and Beethoven. Each has its strengths and its place, and the choice ultimately comes down to your specific needs and circumstances.

System Requirements

System requirements greatly influence the choice of a compressor and a condenser. The type of cooling system (residential, commercial, industrial), the cooling capacity required, and the local climate can all dictate the suitable types and sizes of these components. For instance, in a hot climate, you may need a larger and more efficient condenser to effectively release heat.

Energy Efficiency

Energy efficiency is crucial when choosing between different types of compressors and condensers. While some types of compressors, like the scroll and centrifugal, are known for their high efficiency, others, like reciprocating compressors, might be less so.

Similarly, condenser efficiency can vary based on type and application. Higher energy efficiency translates to lower energy bills and less environmental impact.

Cost Implications

The initial cost, as well as long-term operational costs, play a significant role in choosing between different types of compressors and condensers. While certain types may have a higher upfront cost, they may offer lower energy consumption, resulting in lower operational costs over time.

Maintenance costs should also be factored in, as some types may require more frequent maintenance or have more expensive parts.