Electronic Evaporator Pressure Regulator, or EEPR, is a game-changer for homeowners looking to improve their HVAC or refrigeration systems. But what are they? And how do they work? In this article, we’ll dive into the world of EEPRs, exploring their definition, function, types, and how they can make a real difference in your home. So sit back, relax, and let’s get started!

Table of Contents

Definition and Function of Electronic Evaporator Pressure Regulator

An EEPR is a device that helps maintain the right pressure or temperature in your evaporator coil. Think of it like a thermostat for your fridge or AC, only way smarter and more efficient.

Role in refrigeration and air conditioning systems

EEPRs play a crucial part in controlling the cooling process, ensuring that your AC or fridge runs smoothly and efficiently. Without them, you’d be stuck with a subpar system that wastes energy and money.

Primary benefits and applications

Some of the main advantages of EEPRs include improved system efficiency, reduced energy consumption, and better temperature control. They’re used in various applications, from residential ACs to commercial refrigeration systems.

Types of Electronic Evaporator Pressure Regulators

Not all EEPRs are created equal. There are three main types, each with its unique features and benefits:

Pressure-based regulators

These regulators work by sensing changes in pressure within the evaporator coil and adjusting accordingly. They’re great for systems that need precise pressure control.

Temperature-based regulators

Temperature-based regulators focus on maintaining the desired temperature in the evaporator coil. They’re perfect for systems where temperature control is more critical than pressure control.

Combination regulators

As the name suggests, combination regulators offer the best of both worlds, controlling both pressure and temperature. They’re ideal for complex systems that require precise control over both variables.

Components and Working Principle of Electronic Evaporator Pressure Regulator (EEPRs)

Let’s break down an EEPR into its key components and understand how they work together:

Key Components of Electronic Evaporator Pressure Regulators

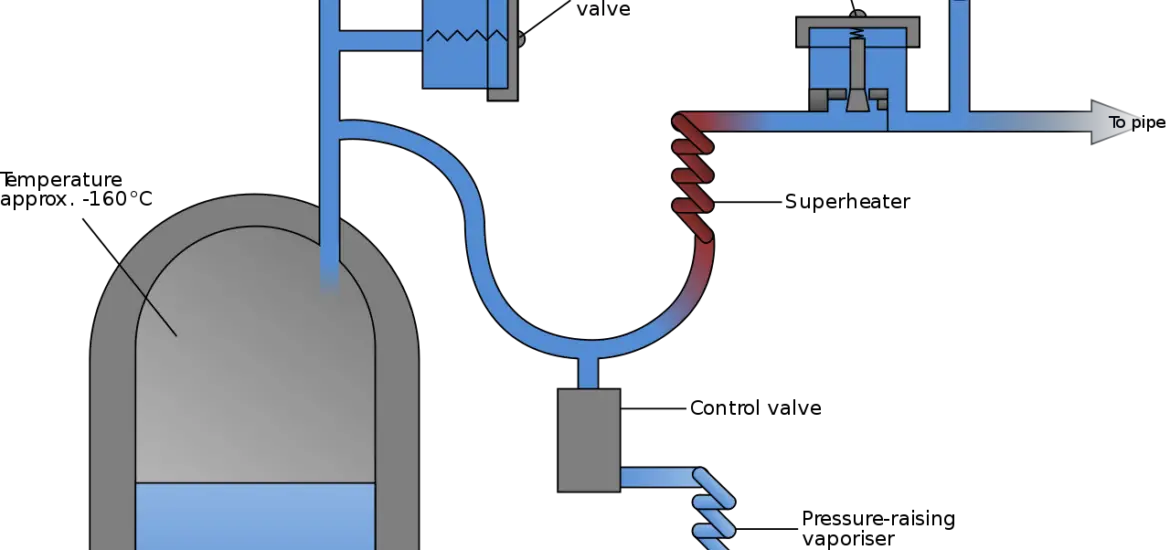

- Electronic control module This is the “brain” of the EEPR, processing data from sensors and controlling the actuator.

- Pressure or temperature sensors These sensors monitor the pressure or temperature in the evaporator coil, sending information to the control module.

- Actuator The actuator receives signals from the control module and moves the control valve accordingly.

- Control valve This valve regulates the flow of refrigerant into User the evaporator coil, maintaining the desired pressure or temperature.

Working Principle of Electronic Evaporator Pressure Regulators

- Sensing evaporator pressure or temperature The sensors detect the current pressure or temperature in the evaporator coil and send this data to the electronic control module.

- Comparison with setpoint The control module compares the sensor data with the desired setpoint and determines if an adjustment is needed.

- Control valve operation If an adjustment is required, the control module sends a signal to the actuator, which then moves the control valve accordingly.

- Feedback loop and adjustment The system continuously monitors the evaporator pressure or temperature and adjusts the control valve as needed, ensuring precise control and optimal system performance.

Installation and Integration with HVAC/R Systems

Now that we know how EEPRs work, let’s talk about how to choose the right one for your system and get it up and running.

Choosing the Right EEPR

- Compatibility with refrigerants Ensure that the EEPR you select is compatible with the refrigerant used in your system.

- Pressure and temperature range considerations Choose an EEPR that can handle the pressure and temperature ranges required by your system.

- System capacity requirements Consider the cooling capacity of your system and select an EEPR that can handle the load.

Installation Process

- Location and orientation Install the EEPR in the appropriate location, following the manufacturer’s guidelines for proper orientation.

- Connection to refrigerant lines Connect the EEPR to the refrigerant lines, ensuring a leak-free and secure connection.

- Electrical wiring and grounding Wire the EEPR according to the manufacturer’s instructions, making sure it’s properly grounded to prevent electrical issues.

- Integration with control systems Integrate the EEPR with your system’s control panel or building automation system, if applicable.

System Start-up and Calibration

- Initial setpoint configuration Configure the desired setpoint for the EEPR according to your system’s requirements.

- Calibration of sensors Calibrate the pressure or temperature sensors as needed to ensure accurate readings.

- Verification of control loop function Verify that the control loop is functioning correctly and making necessary adjustments to the control valve as needed.

Maintenance and Troubleshooting of EEPRs

Like any other component, EEPRs require regular maintenance and occasional troubleshooting. Here’s what you need to know:

Routine Maintenance

- Visual inspection for leaks and damage Periodically inspect the EEPR for any signs of leaks, damage, or wear. Address any issues promptly.

- Verification of sensor accuracy Check the accuracy of the pressure or temperature sensors and recalibrate them if needed.

- Testing actuator and control valve functionality Test the actuator and control valve to ensure they’re operating correctly and efficiently.

Troubleshooting Common Issues

- Erratic pressure or temperature control If you notice inconsistent pressure or temperature control, check for issues with the sensors, control module, or control valve.

- Inaccurate sensor readings If the sensor readings seem off, verify their calibration and replace them if necessary.

- Control valve sticking or malfunction If the control valve isn’t functioning correctly, inspect it for damage or wear and replace it if needed.

- Communication errors with control systems If you’re experiencing communication issues between the EEPR and your control system, check the wiring and connections and ensure proper integration.

Energy Efficiency and Environmental Impact of EEPRs

Using an EEPR doesn’t just improve your system’s performance—it also benefits the environment and your wallet.

To read more in-depth articles on evaporators, click here: Evaporators in Refrigeration: Easy Guide to Understanding Your Fridge’s Unsung Hero

Energy Savings

- Improved system efficiency EEPRs help optimize your system, reducing energy consumption and lowering your utility bills.

- Reduction in compressor cycling By maintaining optimal evaporator pressure or temperature, EEPRs reduce the need for compressor cycling, extending its life and saving energy.

- Optimized evaporator coil performance EEPRs ensure that your evaporator coil operates at peak efficiency, further reducing energy usage.

Environmental Considerations

- Reduction in refrigerant leaks EEPRs help minimize refrigerant leaks, reducing the release of harmful substances into the environment.

- Decreased greenhouse gas emissions By improving energy efficiency, EEPRs contribute to lower greenhouse gas emissions and a smaller carbon footprint.

- Contribution to sustainable HVAC/R practices Implementing EEPRs is an essential step towards more sustainable and eco-friendly HVAC and refrigeration systems.

Conclusion

EEPRs are a game changer for homeowners looking to improve their HVAC and refrigeration systems. They offer numerous advantages, such as:

Summary of EEPRs’ Advantages

- Enhanced system performance and reliability EEPRs provide precise control over pressure and temperature, ensuring that your system operates smoothly and efficiently.

- Energy and environmental benefits With improved efficiency, reduced refrigerant leaks, and decreased greenhouse gas emissions, EEPRs make your system more eco-friendly and cost-effective.

- Future trends and developments in EEPR technology As technology continues to advance, EEPRs will likely become even more effective and widespread, offering even greater benefits for homeowners and the environment.

Now that you’ve got the lowdown on Electronic Evaporator Pressure Regulators, you can make an informed decision about whether they’re right for your home. Don’t miss out on the opportunity to improve your HVAC or refrigeration system’s performance and efficiency while also contributing to a greener future.