Understanding expansion valve stuck open symptoms is crucial for maintaining the efficiency of your cooling system. This comprehensive guide will take you through every aspect of diagnosing and addressing this common problem.

Table of Contents

Expansion Valve Stuck Open Symptoms

An expansion valve that is stuck open is a common problem in cooling systems like air conditioners and refrigerators. It can lead to various symptoms, each of which indicates a malfunction that requires immediate attention. Here, we’ll break down these symptoms and explain why they occur:

Lack of Cooling

When the expansion valve is stuck open, it allows too much refrigerant to enter the evaporator. This excessive flow of refrigerant prevents the system from achieving the desired temperature, resulting in inadequate cooling. The room or space might feel warmer than expected, even if the system is running continuously.

Unusual Noise

A valve stuck in an open position might cause strange noises within the cooling system. The abnormal flow of refrigerant can generate sounds like hissing or gurgling, alerting you to the problem. These noises are often noticeable and different from the standard operating sounds of the system.

Fluctuating System Pressure

The cooling system operates within specific pressure ranges to function efficiently. If the expansion valve is stuck open, the pressure within the system may fluctuate unpredictably. This fluctuation can lead to other components’ wear and tear, potentially resulting in further damage and malfunction.

Frost on the Evaporator Coil

An overabundance of refrigerant entering the evaporator can lead to frosting or icing on the evaporator coil. This frost buildup restricts airflow and reduces the system’s cooling capacity. If you notice ice or frost on the evaporator coil, it’s a clear sign that something is wrong, possibly with the expansion valve.

Increased Energy Bills

When the expansion valve is stuck open, the cooling system struggles to reach the desired temperature, often running for more extended periods or working harder. This increased effort results in higher energy consumption and, consequently, higher utility bills. If you observe a sudden spike in your energy costs without a corresponding increase in usage, the expansion valve might be the culprit.

Understanding these symptoms is essential for early detection and timely repair of an expansion valve stuck open. Regular maintenance and monitoring can help prevent these issues, but recognizing these signs enables you to act quickly, minimizing potential damage and inconvenience.

Diagnosing Expansion Valve Stuck Open Symptoms

Diagnosing the expansion valve stuck open symptoms involves a series of tests and checks:

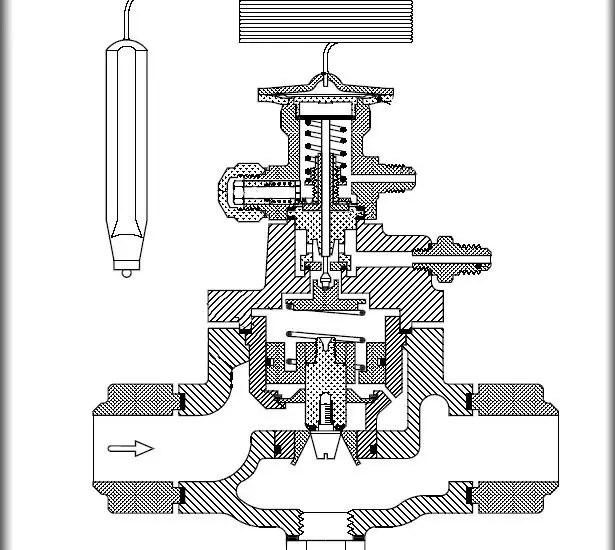

Visual Inspection: Check for any visible damage or abnormalities in the expansion valve.

Pressure Testing: Using pressure gauges like this FavorCOOL HVAC Gauges from Amazon, monitor the system’s pressure to identify any irregularities.

Temperature Monitoring: Measure the temperature at various points to pinpoint any inconsistencies.

Consulting the Manual: Refer to the system’s manual for specific diagnostic procedures for the particular make and model.

These steps will help you accurately diagnose whether the expansion valve is indeed stuck open.

Check out these other related articles…

Electronic Expansion Valve Troubleshooting: Easy 411 Guide

How to Replace Expansion Valve: The Ultimate DIY Guide

Expansion Valve Not Working: Fixed in 5 Easy Steps

How to Clean Expansion Valve: Your Easy 101 Guide

How to Unclog Expansion Valve in 6 Easy Steps

How to Fix an Expansion Valve Stuck Open

If your expansion valve is indeed stuck open, repairing or replacing it might be necessary:

Turn Off the Power: Always begin by turning off the power to the system to ensure safety.

Access the Valve: Open the necessary panels or covers to reach the expansion valve.

Inspect and Repair: Assess the valve for damage and make the necessary repairs or replacements, following the manufacturer’s guidelines.

Test the System: Once repaired, test the system to ensure it’s working correctly, monitoring both temperature and pressure.

Always consult with a professional if you’re uncertain about any part of the process.