This article will provide you with a clear, step-by-step understanding of freon pressure, ensuring your cooling systems operate smoothly and effectively.

Table of Contents

What is Freon Pressure?

Freon pressure is the measure of how much force the refrigerant (commonly referred to as Freon, a brand name that’s become generic) exerts within the cooling system of your air conditioner or refrigerator. This pressure is a critical factor in how your cooling system operates.

The refrigerant cycles through the system, changing from a low-pressure gas to a high-pressure liquid and back. This allows it to absorb heat from inside your home and release it outside.

The correct freon pressure is essential because it ensures that this heat transfer happens efficiently. If the pressure is too low or too high, it can lead to poor cooling performance, increased energy consumption, and even damage to the system. It’s a key indicator of the health and proper functioning of your cooling system.

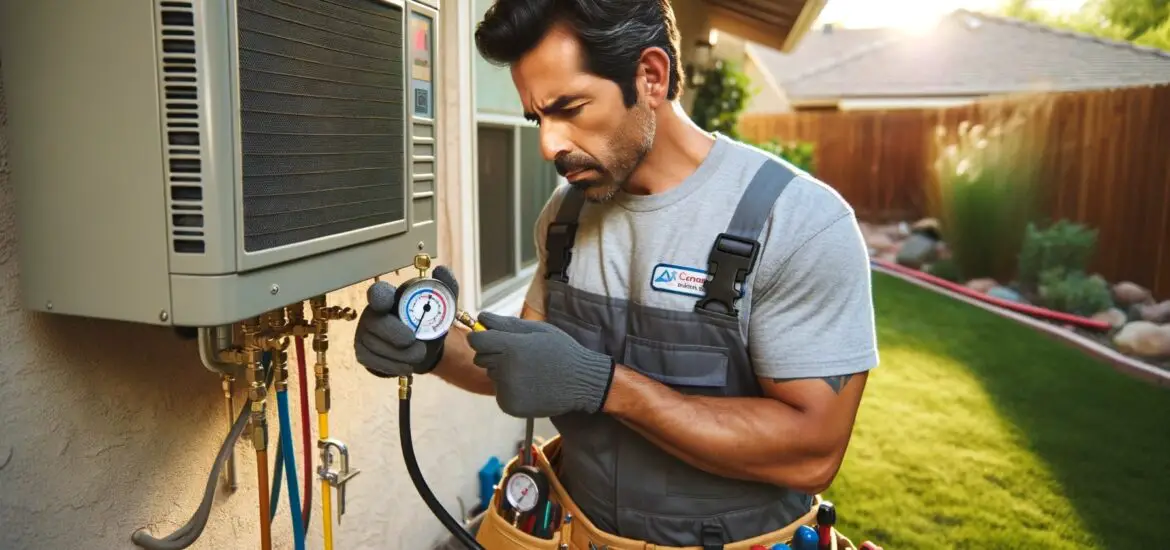

How to Measure Freon Pressure

Measuring the freon pressure in your system requires a tool called a manifold gauge set. This set includes two gauges: a high-pressure gauge (red) and a low-pressure gauge (blue), along with corresponding hoses.

You can get this BENTISM 4-Way AC Manifold Gauge Set from Walmart.

Here’s a step-by-step guide to measuring freon pressure:

Ensure Safety: Before starting, make sure your AC system is turned off to avoid any accidents. Wear safety glasses and gloves for protection.

Locate Service Valves: Find the low-side and high-side service valves on your outdoor unit. These are access points to connect your gauge hoses.

Connect the Gauges: Attach the blue hose to the low-side service valve and the red hose to the high-side valve. Ensure the connections are tight and secure to prevent any refrigerant leaks.

Start the System and Measure: Turn on your AC system. Let it run for about 15 minutes to stabilize before taking readings. Observe the pressure readings on both gauges.

Compare with Standard Readings: Check the manufacturer’s specifications for your AC model to find the recommended pressure range. Your readings should fall within this range for optimal performance.

Note: The correct pressure readings can vary significantly depending on the refrigerant type (like R-22 or R-410A) and the ambient temperature conditions. Always refer to your system’s manual or a professional for the correct specifications.

Understanding Pressure Readings

Understanding the pressure readings from your gauge set is crucial in assessing the health of your cooling system. Typically, the low-side gauge measures suction pressure, indicating how the system is pulling the refrigerant. On the other hand, the high-side gauge measures the pressure after the refrigerant has been compressed.

Normal pressure readings vary based on the type of refrigerant used and the current operating conditions. For instance, R-22 systems usually operate at lower pressures than R-410A systems.

Unusual readings can indicate various issues. Low pressure might suggest a refrigerant leak or a failing compressor. High pressure could point to a blockage in the system or an overcharged condition.

Troubleshooting Common Pressure Issues

Encountering issues with freon pressure can be indicative of several underlying problems:

Refrigerant Leaks: Low pressure often suggests a refrigerant leak. This can be due to loose fittings, worn service valves, or physical damage to the refrigerant lines. Identifying and repairing leaks is crucial for system efficiency and environmental safety.

Compressor Issues: The compressor is responsible for pressurizing the refrigerant. If it’s malfunctioning, you might observe low pressure on both gauges. Signs of compressor failure include strange noises, tripped breakers, or a hot-to-touch compressor.

Condenser Problems: A dirty or blocked condenser can lead to high pressure. This is because the heat exchange process is hindered, causing the system to work harder. Regularly cleaning the condenser coils is a simple yet effective way to prevent this issue.

Seek Professional Help: If the problem is complex or if you’re unsure, it’s always best to consult with a professional HVAC technician. They can provide a more detailed diagnosis and safe repair solutions.

Maintaining Optimal Freon Pressure

Maintaining the right freon pressure is key to ensuring your cooling system runs efficiently and lasts longer. Regular maintenance tasks include:

Regular Checkups: Periodically check your system’s pressure levels and compare them with the recommended specifications.

Leak Inspections: Routinely inspect your system for any signs of refrigerant leaks and address them promptly.

Keep It Clean: Ensure that the condenser and evaporator coils are clean and free from debris, as this can affect pressure levels and overall system efficiency.

Professional Servicing: Have your system professionally inspected and serviced at least once a year. This not only helps maintain proper freon pressure but can also identify potential issues before they become major problems.

By following these steps, you can ensure that your cooling system operates at its best, providing effective cooling while minimizing the risk of breakdowns and costly repairs.