Refrigerant dryer dew point might seem like a mouthful, right? It’s one of those techy terms you’d likely stumble across while deep-diving into the specifics of compressed air systems. But guess what? It’s simpler than it sounds. Let’s make sense of it together.

Table of Contents

Understanding Dew Point

Picture this: it’s a cold morning, and you see tiny droplets formed on the outside of your window – that’s dew. The ‘dew point’ is just the temperature at which this dew forms. In our world of compressed air systems, the dew point gets a bit more complex, but stay with me.

Definition of Refrigerant Dryer Dew Point

Dew point, in the simplest terms, is the temperature at which air becomes saturated with moisture. When we cool the air below this point, the excess water starts to condense out – like how our cold window causes water in warm air to condense into dew.

Importance of Dew Point in Compressed Air Systems

You might be thinking, “why does dew point even matter?” It’s critical because excess moisture in compressed air systems can cause a whole host of problems, from corroded equipment to compromised product quality. By maintaining the right dew point, we keep our systems running smoothly and efficiently.

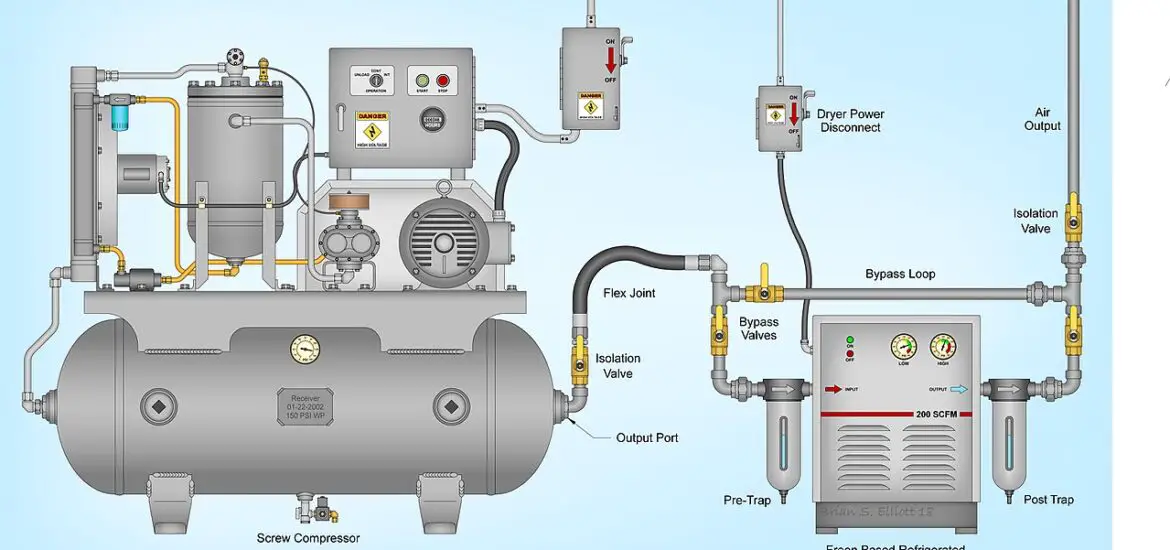

Working of a Refrigerant Dryer

So, how does a refrigerant dryer fit into all this? Think of a refrigerant dryer as the bouncer at the club, keeping unwanted moisture out. It cools the compressed air, causing moisture to condense out before it can cause any problems. Here’s how it works:

Compressed Air Cooling Process

First, the dryer takes in hot, moist compressed air. This air then passes through a heat exchanger, where it’s cooled down. The cool temperatures make the moisture condense out of the air, just like dew forming on a cold window. And voila – dry air!

Refrigeration Cycle in a Dryer

The refrigeration cycle in the dryer is what makes the magic happen. The refrigerant – a special fluid that’s really good at absorbing and releasing heat – cools the air down. It’s a crucial process in achieving our desired dew point.

Read more detailed articles on refrigerants here – Articles on Refrigerants: The Ultimate Guide to Understanding Them

Factors Influencing Dew Point in a Refrigerant Dryer

Here’s the thing: not every dryer will give you the same dew point. Various factors come into play. Let’s see what these are:

Inlet Air Temperature

The temperature of the incoming air can have a major effect on dew point. The hotter the air, the more moisture it can hold, and the higher the dew point.

Refrigerant Type and Pressure

The type of refrigerant used, and the pressure at which it operates, can greatly impact dew point. It’s a delicate balancing act – the wrong refrigerant or pressure can mean the difference between a well-functioning system and a moisture-ridden mess.

Air Flow Rate

Ever try to dry something off by blowing on it? The speed of your breath affects how quickly it dries. Same with air in a dryer – the flow rate impacts the dew point.

Measuring Dew Point in a Refrigerant Dryer

So, how do you know if your dryer is doing its job? By measuring the dew point, of course. Here’s how it’s done:

Dew Point Meters and Sensors

Thanks to the wonders of modern technology, we’ve got a range of meters and sensors designed specifically to measure dew point. These handy little devices give you a clear reading, so you can be sure your system is performing at its best.

Dew Point Sampling Techniques

When it comes to measuring dew point, where and how you take your samples can make a big difference. But you’re probably thinking, “How so?” Well, let’s demystify that:

Sampling Location

The place where you extract your air sample from can impact your dew point readings. Samples should typically be taken after the refrigerant dryer, as this will reflect the moisture content of the air at its driest point. Sampling from here allows you to accurately assess how effectively your dryer is doing its job. It’s kind of like taking a cake out of the oven to check if it’s ready; you wouldn’t check it halfway through baking, right?

Sampling Frequency

How often should you measure the dew point? It’s a bit like asking how often should you check the weather forecast. For most industries, regular daily checks can provide a good sense of your system’s performance, but this might vary depending on the specific needs of your application. The key is consistency; regular monitoring can help you spot trends and address issues before they become major headaches.

Sampling Method

The method you use to take samples also matters. There are two primary methods: continuous and spot-check sampling. Continuous sampling gives you real-time data, which is great for systems that need close monitoring. Spot-check sampling, on the other hand, is done at intervals and can be a good choice for systems with less critical moisture levels. Picking the right method is like choosing the right tool for a job, it can make your life a whole lot easier!

Optimizing Dew Point in a Refrigerant Dryer

Now, we’re on to the good stuff: how to optimize the dew point in your dryer for peak performance. Ready?

Regular Maintenance and Inspection

Just like your car needs regular check-ups, your dryer does too. Keeping your dryer in tip-top shape can help maintain an optimal dew point.

Proper Sizing and Operation of Dryers

Imagine trying to fit a big foot into a small shoe – it just doesn’t work, right? Same goes for your dryer. The right size and correct operation are key to achieving your ideal dew point.

Conclusion

And there we have it, folks! We’ve journeyed through the intriguing world of refrigerant dryer dew point, and hopefully, we’ve made it a little less daunting. Remember, achieving the right dew point is crucial for your compressed air system’s health and performance. So, keep those dew points in check and your system will thank you for it!