Ever been curious about the refrigerant dryer working principle? Well, it’s a fascinating process that efficiently cools and dries compressed air. It condenses the water vapor from the air supply, removes it, and voila! You’re left with cool, dry air. Neat, right?

Table of Contents

Understanding Refrigerant Dryers

What is a Refrigerant Dryer?

You might have come across a refrigerant dryer if you’ve spent some time around air conditioning systems or industrial machinery. They’re these awesome devices that play a critical role in drying out compressed air, all in the name of efficient operations and prolonging the lifespan of equipment.

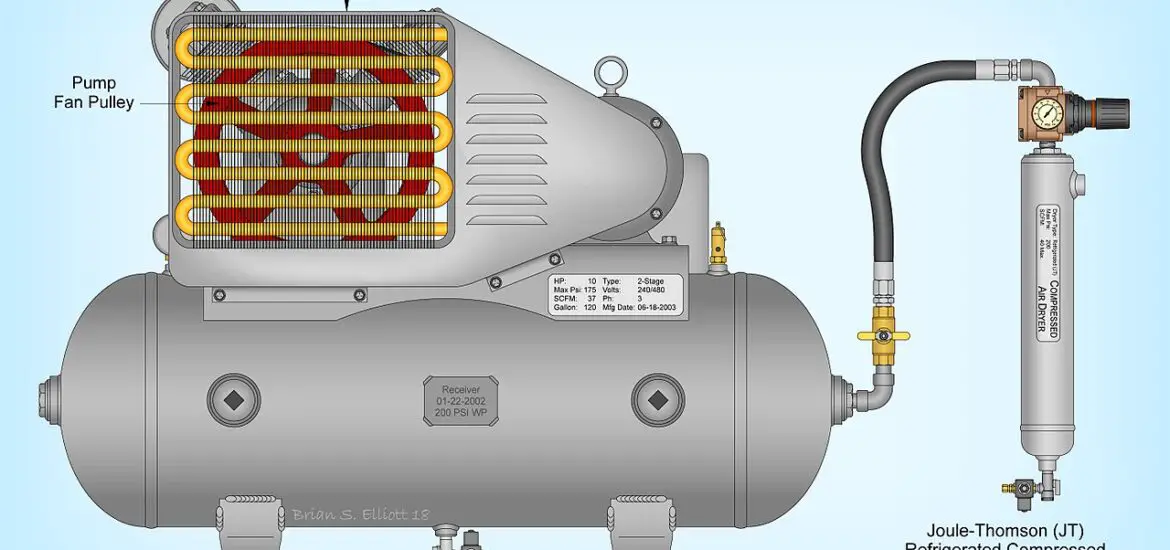

Key Components of a Refrigerant Dryer

Ever took a peek inside a refrigerator? It’s pretty similar to a refrigerant dryer, with a few key components like a compressor, a condenser, an evaporator, and an expansion valve. These elements work together like a well-rehearsed orchestra.

Refrigerant Dryer Working Principle

The Cooling Process

Remember when we talked about that orchestra? Well, the cooling process is like the opening act. Compressed air enters the system and is cooled down in the heat exchanger – it’s the star of the show!

How the Heat Exchanger Works

Think of the heat exchanger as the maestro of the cooling process. It guides the compressed air, reducing its temperature to get it just right for the next step.

The Role of the Refrigerant

Then comes the refrigerant, the unsung hero of the whole operation. It further cools the air, facilitating the condensation of water vapor.

The Separation Process

Once all that cooling and condensing is done, it’s time for the separation process. It’s like cleaning up after a big party, removing water and oil from the cooled air.

Role of the Separator

And who does the clean-up? It’s the separator, the diligent custodian that ensures the air leaving the dryer is as dry as a bone.

Discharging the Condensate

But we’re not done yet. The condensed water is removed from the system, like saying goodbye to the last guest at the party.

The Reheating Process

Last but not least, the reheating process is like the encore of this symphony. The dried air is reheated before it exits the system.

Benefits of the Reheating Process

Why reheat the air, you ask? Well, it reduces the relative humidity of the output air and prevents condensation downstream. It’s like getting a takeaway after a good meal – it just adds to the overall satisfaction!

Read on refrigerants here – Articles on Refrigerants: The Ultimate Guide to Understanding Them

Types of Refrigerant Dryers

Cycling Refrigerant Dryers

Think of cycling refrigerant dryers as the marathon runners. They operate continuously, varying their cooling capacity to match the load conditions.

Non-Cycling Refrigerant Dryers

Then you’ve got non-cycling refrigerant dryers. They’re like the sprinters of the drying world, working at a constant cooling capacity no matter the conditions.

Conclusion: Refrigerant Dryer Working Principle

And there you have it. The refrigerant dryer working principle is a fascinating process, efficiently delivering dry, clean air with each cycle. From the cooling to the separation, each stage plays a significant role. So next time you think of dry, clean air, you’ll know a refrigerant dryer is doing its thing behind the scenes!