Refrigerant to water heat exchanger: ever heard of it? As a homeowner, you’re always looking for ways to save on energy bills and make your home more eco-friendly. One solution that’s gaining traction is using heat exchangers in your HVAC system. In this article, we’ll break down what heat exchangers do, why they’re important, and how they can help you save money and the environment. Ready to dive in? Let’s go!

Table of Contents

Introduction to Heat Exchanger Refrigerant to Water

Basic concept of heat exchangers

Definition and function

So, what exactly is a heat exchanger? Simply put, it’s a device that transfers heat from one medium to another. In our case, we’re talking about transferring heat from a refrigerant to water. This process helps efficiently cool your home without using as much energy as traditional systems. Cool, huh?

Types of heat exchangers

There are a few different types of heat exchangers, each with its pros and cons. The most common ones you’ll come across are shell and tube, plate, coaxial, and microchannel. Don’t worry, we’ll dive into the specifics of each later on.

Applications in HVAC and refrigeration systems

Heat exchangers play a big role in many heating, ventilation, and air conditioning (HVAC) systems, as well as refrigeration systems. They help to ensure that these systems are energy-efficient and environmentally friendly. That’s a win-win, right?

Importance of refrigerant to water heat exchanger

Energy efficiency

By using a heat exchanger, you can significantly improve the energy efficiency of your HVAC system. This means lower energy bills for you and a smaller carbon footprint for your home. Sounds like a no-brainer!

Sustainable cooling solutions

Heat exchangers offer a more sustainable cooling solution compared to traditional systems. By using less energy and reducing greenhouse gas emissions, you’re doing your part to help combat climate change. Go you!

Waste heat recovery

Another great benefit of heat exchangers is their ability to recover waste heat. This means they can use the heat generated by your HVAC system to do things like heat your water, giving you even more bang for your buck.

Design and Components of Heat Exchanger Refrigerant to Water

Heat exchanger designs for refrigerant to water applications

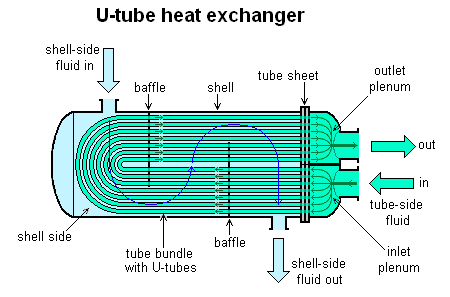

Shell and tube heat exchangers

These bad boys consist of a series of tubes within a shell. One fluid flows through the tubes, while the other flows around them, transferring heat as they go. They’re pretty versatile and can handle a range of temperatures and pressures.

Plate heat exchangers

Imagine a stack of metal plates with grooves that create channels for fluids to flow through. That’s a plate heat exchanger! They’re compact, efficient, and great at handling small temperature differences between fluids.

Coaxial heat exchangers

Coaxial heat exchangers have an inner tube within an outer tube, creating two separate flow channels. The refrigerant and water flow through these channels, transferring heat as they go. They’re compact, easy to maintain, and work well in tight spaces.

Microchannel heat exchangers

These tiny wonders consist of flat tubes with multiple microchannels that allow fluids to flow through. They’re lightweight, super-efficient, and perfect for situations where space is limited. Plus, they’re more resistant to corrosion!

Material selection for heat exchangers

Copper

Copper is a popular choice for heat exchanger materials because of its excellent thermal conductivity and resistance to corrosion. Plus, it’s easy to work with and relatively affordable. What’s not to love?

Aluminum

Another great option is aluminum. It’s lightweight, corrosion-resistant, and has good thermal conductivity. Plus, it’s often more affordable than copper, making it a solid choice for budget-conscious homeowners.

Stainless steel

Stainless steel is a more durable option, offering excellent corrosion resistance and good heat transfer capabilities. It’s a bit more expensive than other materials, but it’s worth considering if you want something that will last.

Titanium

For those who want the best of the best, titanium is the way to go. It’s incredibly strong, lightweight, and resistant to corrosion. However, it comes with a hefty price tag, so it’s not for everyone.

Components of heat exchangers

Tubes

Tubes are the main component of many heat exchangers, allowing fluids to flow through and transfer heat. They come in various sizes, materials, and configurations, depending on the specific heat exchanger design.

Plates

Plates are the primary component of plate heat exchangers, providing the surface area needed for efficient heat transfer. They’re typically made from metal and can be flat, corrugated, or embossed.

Fins

Fins are thin metal pieces that help increase the surface area for heat transfer, making the heat exchanger more efficient. They can be found in many different heat exchanger designs and are especially useful in air-to-water systems.

Headers

Headers are used to connect the tubes or plates in a heat exchanger, allowing fluids to flow in and out. They play an essential role in directing fluid flow and maintaining proper pressure levels within the system.

Thermodynamics and Heat Transfer in Heat Exchanger Refrigerant to Water

Basic thermodynamic principles

First law of thermodynamics

Remember the first law of thermodynamics? Energy can’t be created or destroyed, only converted from one form to another. This principle is at the heart of heat exchangers, as they convert heat energy from one fluid to another without losing any energy in the process.

Second law of thermodynamics

The second law of thermodynamics states that heat naturally flows from hot to cold. This is key to understanding how heat exchangers work, as they transfer heat from the hotter refrigerant to the cooler water, ultimately cooling your home.

Refrigeration cycle

The refrigeration cycle is the process that allows your HVAC system to cool your home. It involves the refrigerant absorbing heat from the indoor air, releasing that heat through a heat exchanger, and then cooling the air before it’s blown back into your home. Pretty neat, huh?

Heat transfer mechanisms

Conduction

Conduction is the transfer of heat through a solid material, like the metal plates or tubes in a heat exchanger. It’s a key player in making heat exchangers efficient and effective at transferring heat.

Convection

Convection is the transfer of heat through the movement of fluids, like the refrigerant and water in your heat exchanger. It’s essential for ensuring that heat is evenly distributed and effectively transferred between the two fluids.

Radiation

Radiation is the transfer of heat through electromagnetic waves, like sunlight. While it’s not a significant factor in most heat exchangers, it can still play a role in some designs and should be considered when optimizing efficiency.

Enhancing heat transfer in heat exchangers

Extended surfaces

Extended surfaces, like fins, can help increase the surface area for heat transfer, making your heat exchanger more efficient. They’re especially useful in air-to-water systems where space is limited.

Turbulators

Turbulators are devices that create turbulence in the fluid flow, which enhances heat transfer by increasing the mixing of fluids. They can be a useful addition to some heat exchanger designs, helping to improve efficiency even further.

Optimal flow patterns

Designing a heat exchanger with optimal flow patterns ensures that heat is evenly distributed and effectively transferred between the two fluids. This can involve things like counter-flow or cross-flow arrangements, depending on the specific design.

Sizing and Selection of Heat Exchanger Refrigerant to Water

Factors affecting sizing and selection

Required heat transfer rate

The amount of heat you need to transfer will play a big role in determining the size and type of heat exchanger you’ll need. This will depend on factors like the size of your home, your climate, and your desired indoor temperature.

Temperature profiles

The temperature difference between the fluids in your heat exchanger will also affect its size and design. A greater temperature difference will typically require a larger heat exchanger to ensure adequate heat transfer.

Flow rates

The flow rates of the fluids in your heat exchanger will also impact its size and design. Higher flow rates can lead to more efficient heat transfer, but may also require a larger heat exchanger to handle the increased flow.

Pressure drop

Pressure drop is the decrease in pressure that occurs as fluids flow through a heat exchanger. It’s essential to consider when sizing and selecting a heat exchanger, as excessive pressure drop can reduce efficiency and even damage your system. Balancing heat transfer and pressure drop is key to finding the perfect heat exchanger for your needs.

Sizing calculations

Log mean temperature difference (LMTD)

LMTD is a crucial factor in sizing heat exchangers. It takes into account the temperature difference between the fluids at the inlet and outlet, helping you determine the heat transfer rate and size of your heat exchanger. The greater the LMTD, the more efficient the heat transfer process will be.

Overall heat transfer coefficient (U)

The overall heat transfer coefficient (U) represents how efficiently a heat exchanger can transfer heat between fluids. It depends on factors like the materials used, the design of the heat exchanger, and the fluid properties. Higher values of U mean better heat transfer efficiency, helping you choose the right heat exchanger for your needs.

Heat transfer surface area (A)

The heat transfer surface area (A) is the total area available for heat transfer in a heat exchanger. Larger surface areas generally lead to more efficient heat transfer, but can also result in a larger, more expensive heat exchanger. Balancing surface area and cost is essential when selecting the right heat exchanger for your home.

Heat exchanger selection software

HTRI Xchanger Suite

Need some help selecting the perfect heat exchanger? The HTRI Xchanger Suite is a software package designed to help you analyze and design heat exchangers. It offers advanced tools and models for optimizing performance and ensuring that you choose the best heat exchanger for your needs.

Aspen Exchanger Design & Rating

Another great option for heat exchanger selection is the Aspen Exchanger Design & Rating software. It offers powerful tools for designing and optimizing heat exchangers, helping you find the perfect fit for your home and budget.

EJ Bowman Heat Exchanger Selection Tool

If you’re looking for a user-friendly heat exchanger selection tool, the EJ Bowman Heat Exchanger Selection Tool might be just what you need. It offers an easy-to-use interface and a wide range of heat exchanger options to choose from, making the selection process a breeze.

Installation, Maintenance, and Troubleshooting

Installation guidelines

Proper placement

Proper placement of your heat exchanger is essential for optimal performance. Be sure to follow the manufacturer’s guidelines and consult with a professional installer to ensure your heat exchanger is installed in the best possible location.

Piping connections

Properly connecting your heat exchanger to your HVAC system is crucial for ensuring efficient heat transfer and preventing leaks. Be sure to follow the manufacturer’s instructions and consult with a professional installer for best results.

Expansion and contraction considerations

Heat exchangers can expand and contract as they heat up and cool down, so it’s important to account for this when installing your system. Ensure that your heat exchanger is properly secured and has enough space to accommodate any expansion or contraction that may occur.

Leak testing

Once your heat exchanger is installed, it’s important to perform a leak test to ensure there are no issues with your connections or the heat exchanger itself. This will help prevent costly repairs and potential damage to your home or HVAC system.

Maintenance procedures

Regular cleaning

Keeping your heat exchanger clean is essential for maintaining its efficiency and preventing issues like fouling or scaling. Be sure to regularly inspect and clean your heat exchanger according to the manufacturer’s recommendations.

Inspecting for wear and corrosion

Regularly inspecting your heat exchanger for signs of wear and corrosion can help prevent costly repairs and ensure your system continues to operate efficiently. If you notice any issues, consult with a professional technician for assistance.

Monitoring pressure and temperature

Keeping an eye on the pressure and temperature of your heat exchanger can help you identify potential issues before they become major problems. Regularly monitor these parameters and consult with a technician if you notice any unusual fluctuations.

Troubleshooting common issues

Reduced heat transfer efficiency

If you notice a decrease in your heat exchanger’s efficiency, it may be due to fouling, scaling, or other issues. Regular maintenance and cleaning can help prevent these problems and keep your system running smoothly.

Fouling and scaling

Fouling and scaling can reduce the efficiency of your heat exchanger and even lead to damage. Regular cleaning and proper water treatment can help prevent these issues and keep your heat exchanger in tip-top shape.

Leaks and corrosion

Leaks and corrosion can lead to costly repairs and reduced efficiency in your heat exchanger. Regular inspections and maintenance can help catch these issues early and prevent further damage to your system.

Mechanical failure

Mechanical failure of your heat exchanger can be caused by a variety of factors, including wear, corrosion, or manufacturing defects. Regular maintenance and inspections can help identify potential issues before they become serious problems.

Future Trends and Innovations

Advanced materials

Carbon-based materials

Carbon-based materials like graphene and carbon nanotubes are showing promise for use in heat exchangers due to their high thermal conductivity and lightweight properties. They could potentially revolutionize the industry in the coming years.

Metal matrix composites

Metal matrix composites (MMCs) combine the best properties of metals and other materials, offering improved thermal conductivity and resistance to wear and corrosion. They could lead to more efficient and durable heat exchangers in the future.

Nanotechnology

Nanotechnology is opening up new possibilities for heat exchanger design, with the potential for creating ultra-efficient, compact heat exchangers with superior thermal performance. This could be a game-changer in the industry, offering even more sustainable and efficient cooling solutions.

Innovative designs and configurations

3D printed heat exchangers

3D printing technology is allowing for the development of custom heat exchanger designs with complex geometries and improved performance. This could lead to more efficient and tailor-made heat exchangers for specific applications, offering homeowners more flexibility and better performance.

Multi-functional heat exchangers

Multi-functional heat exchangers are an emerging trend, combining multiple functions like heating, cooling, and energy recovery into a single unit. This can lead to more compact and efficient systems, saving space and energy in your home.

Compact heat exchangers

As technology advances, heat exchangers are becoming more compact and efficient. Smaller, high-performance heat exchangers are ideal for residential applications, offering improved performance with a smaller footprint.

Environmental and Regulatory Considerations

Environmental impact

Reducing greenhouse gas emissions

By improving the efficiency of heat exchangers and HVAC systems, we can reduce greenhouse gas emissions and help combat climate change. Choosing a refrigerant to water heat exchanger system is one way homeowners can contribute to a more sustainable future.

Optimizing energy consumption

Energy-efficient heat exchangers can help homeowners optimize their energy consumption, reducing energy costs and contributing to a more sustainable future. It’s a win-win situation for both the environment and your wallet!

Minimizing water usage

Water scarcity is a growing concern, and using refrigerant to water heat exchanger systems can help minimize water usage in cooling applications. This can help conserve valuable resources and reduce the impact on the environment.

Refrigerant regulations

Montreal Protocol

The Montreal Protocol is an international treaty designed to protect the ozone layer by phasing out the production and use of harmful substances, including certain refrigerants. This has led to the development of more environmentally friendly refrigerants and heat exchanger technologies.

Kigali Amendment

The Kigali Amendment to the Montreal Protocol aims to phase down the production and use of hydrofluorocarbons (HFCs), which are potent greenhouse gases. This is driving the development of new, more sustainable refrigerants and heat exchanger designs.

Regional and national regulations

In addition to international treaties, regional and national regulations also impact the choice of refrigerants and heat exchanger technologies. It’s important to stay informed about these regulations and choose a heat exchanger that complies with all applicable laws and guidelines.

Standards and certifications

ASHRAE standards

ASHRAE standards provide guidelines for the design, installation, and maintenance of HVAC systems, including heat exchangers. Following these standards can help ensure the safe and efficient operation of your refrigerant to water heat exchanger system.

ISO standards

ISO standards also provide guidance on the design, performance, and testing of heat exchangers. Complying with these standards can help ensure the quality and performance of your heat exchanger system.

AHRI certification

AHRI certification is a voluntary program that verifies the performance of heat exchangers and other HVAC equipment. Choosing a certified heat exchanger can give you confidence in the performance and efficiency of your system.

Case Studies and Real-World Applications

Residential HVAC systems

Air-to-water heat pump systems

Air-to-water heat pump systems utilize heat exchangers to transfer heat from the air to water, providing efficient heating and cooling for homes. These systems are becoming more popular due to their energy efficiency and versatility.

Geothermal heat pump systems

Geothermal heat pump systems rely on heat exchangers to transfer heat between the ground and water, offering an environmentally friendly and highly efficient heating and cooling solution for homeowners.

Hybrid systems

Hybrid systems combine the best of both air-to-water and geothermal heat pump systems, offering even greater efficiency and flexibility for homeowners. Refrigerant to water heat exchanger technology plays a crucial role in the performance of these advanced systems.

Commercial and industrial applications

Process cooling and heating

Refrigerant to water heat exchanger systems are widely used in commercial and industrial applications for process cooling and heating, providing precise temperature control and energy-efficient solutions for a variety of industries.

Data center cooling

Data centers generate a significant amount of heat, and efficient cooling is essential for maintaining optimal performance. Refrigerant to water heat exchanger systems offer an effective and energy-efficient solution for data center cooling applications.

District cooling and heating

District cooling and heating systems provide centralized heating and cooling for multiple buildings, and refrigerant to water heat exchanger technology is essential for their efficient operation. These systems offer numerous benefits, including reduced energy consumption and lower greenhouse gas emissions.

Waste heat recovery and energy optimization

Combined heat and power (CHP) systems

Combined heat and power systems, also known as cogeneration systems, generate both electricity and useful heat, improving overall energy efficiency. Refrigerant to water heat exchanger technology plays a critical role in these systems, capturing waste heat and using it for heating or cooling applications.

Organic Rankine cycle (ORC) systems

Organic Rankine cycle systems are used to generate electricity from low-temperature heat sources like waste heat from industrial processes. Refrigerant to water heat exchanger technology is essential for these systems, helping to improve energy efficiency and reduce greenhouse gas emissions.

Adsorption and absorption chillers

Adsorption and absorption chillers use refrigerant to water heat exchanger technology to convert waste heat into cooling, providing an energy-efficient and sustainable solution for air conditioning and refrigeration applications.

Conclusion

Summary of key concepts

Refrigerant to water heat exchanger systems are a vital component of energy-efficient and sustainable HVAC systems, providing numerous benefits for homeowners, commercial, and industrial applications. Understanding their design, operation, and maintenance is key to maximizing their potential benefits.

Future outlook and challenges

As technology advances and environmental concerns grow, refrigerant to water heat exchanger systems will continue to evolve and improve. Innovations in materials, design, and regulation will shape the future of this essential technology, offering even more efficient and sustainable solutions for heating and cooling needs. However, challenges remain, such as developing more advanced materials and designs, adapting to changing regulations, and ensuring that these systems are accessible and affordable for all homeowners.

The role of refrigerant to water heat exchanger in sustainable development

Refrigerant to water heat exchanger systems play a vital role in promoting sustainable development by improving energy efficiency, reducing greenhouse gas emissions, and minimizing water usage. By choosing these systems, homeowners, businesses, and industries can contribute to a more sustainable and environmentally friendly future.