Refrigerant vapor density is a key aspect of HVAC systems that often flies under the radar. But did you know that it can make a significant difference in how efficiently your system operates? In this article, we’ll dive into the nitty-gritty of refrigerant vapor density and explore its impact on HVAC performance. So, let’s get started!

Table of Contents

Introduction to Refrigerant Vapor Density

First off, what exactly is refrigerant vapor density? In simple terms, it’s the mass of refrigerant vapor per unit volume. Why should we care about it? Well, it plays a crucial role in the performance of HVAC/R systems, affecting heat transfer efficiency, pressure drop, and compressor performance. Various factors, such as temperature and pressure, influence refrigerant vapor density, making it an essential aspect to consider in HVAC system design and operation.

Measurement of Refrigerant Vapor Density

Before we dive deeper, let’s understand how refrigerant vapor density is measured. We have different units and methods to measure this critical property.

SI units

Refrigerant vapor density is commonly measured in kilograms per cubic meter (kg/m³) in the International System of Units (SI).

Imperial units

In the Imperial system, it is measured in pounds per cubic foot (lb/ft³).

Gas pycnometer

One popular method to measure vapor density is using a gas pycnometer, which determines the volume of a gas sample at a specific temperature and pressure.

Gravimetric technique

The gravimetric technique involves weighing a known volume of gas, which can then be used to calculate the vapor density.

Air displacement method

The air displacement method measures the volume of gas displaced by a known mass of refrigerant, from which the vapor density can be calculated.

Common Refrigerants and Their Vapor Densities

There’s a wide range of refrigerants out there, each with its unique vapor density. Let’s take a quick look at some of the most common ones and compare their vapor densities.

Chlorofluorocarbons (CFCs)

CFCs, like R-12 and R-114, were once widely used but have been phased out due to their ozone-depleting properties. They generally have high vapor densities compared to other refrigerants.

Hydrochlorofluorocarbons (HCFCs)

HCFCs, such as R-22, replaced CFCs for a time but are also being phased out because they still contribute to ozone depletion. They have moderate vapor densities.

Hydrofluorocarbons (HFCs)

HFCs, like R-134a and R-410A, are currently popular as they don’t deplete the ozone layer. However, they have a high global warming potential (GWP). Their vapor densities vary depending on the specific refrigerant.

Hydrofluoroolefins (HFOs)

HFOs, such as R-1234yf and R-1234ze, are emerging as alternatives to HFCs due to their low GWP. Their vapor densities also vary based on the specific refrigerant.

Natural refrigerants

Natural refrigerants like ammonia (R-717), carbon dioxide (R-744), and hydrocarbons (R-290, R-600a) have low GWP and ODP. They have varying vapor densities depending on the specific refrigerant.

Read more about refrigerants here – – Vapor Refrigeration: Easy Guide to Keeping Things Chill

Refrigerant Vapor Density in System Design and Operation

Now that we know a bit more about refrigerant vapor density and the various refrigerants available, let’s explore its impact on system performance and design.

Heat transfer efficiency

Refrigerant vapor density directly affects heat transfer efficiency in HVAC systems. Higher vapor density typically leads to better heat transfer performance, making the system more energy-efficient.

Pressure drop and compressor performance

Vapor density also influences pressure drop and compressor performance. Higher vapor densities usually result in higher pressure drops, which can reduce compressor efficiency. Therefore, it’s essential to balance the benefits of heat transfer efficiency with potential negative impacts on compressor performance.

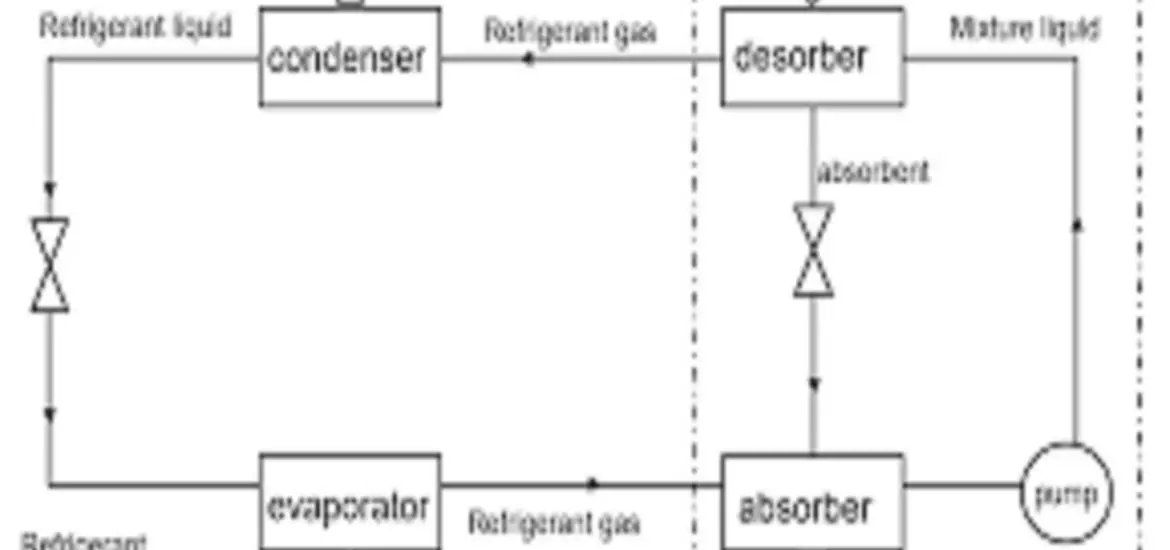

Compatibility with system components

Choosing the right refrigerant with the appropriate vapor density is crucial for ensuring compatibility with system components, such as evaporators, condensers, and piping. Incompatible refrigerants can lead to reduced system efficiency and potential damage to components.

Refrigerant charge considerations

Refrigerant vapor density also affects the required refrigerant charge in a system. Higher vapor density refrigerants may require lower charge levels, reducing the overall refrigerant volume and, consequently, the system’s environmental impact.

Flammability and toxicity

Safety is always a top priority. When selecting a refrigerant, it’s important to consider its vapor density in relation to flammability and toxicity. Some refrigerants with high vapor densities may have increased flammability or toxicity risks, so proper safety measures must be taken.

Leak detection and response

Refrigerant vapor density can also influence leak detection and response. Heavier refrigerants tend to settle in low-lying areas, while lighter refrigerants may disperse more readily. This can impact the placement and effectiveness of leak detection sensors and the appropriate response measures.

Future Trends in Refrigerant Vapor Density

As we look to the future, new developments in refrigerant technology and system design promise exciting changes in the world of refrigerant vapor density.

Low-GWP refrigerants

There is an ongoing push to develop low-GWP refrigerants with optimal vapor densities to minimize environmental impact while maintaining or improving system performance.

Performance-enhancing additives

Research is underway to explore the use of additives that can enhance the performance of refrigerants, potentially allowing for lower vapor densities while maintaining heat transfer efficiency and other desired properties.

Variable refrigerant flow (VRF) systems

VRF systems, which allow for precise control of refrigerant flow, are becoming more popular. These systems can help optimize the balance between refrigerant vapor density and system performance, leading to improved energy efficiency.

Energy-efficient heat exchangers

Innovations in heat exchanger design can help to maximize heat transfer efficiency with refrigerants of varying vapor densities, further enhancing the performance of HVAC systems.

Conclusion

In conclusion, refrigerant vapor density plays a significant role in the efficiency and performance of HVAC/R systems. By understanding its importance and selecting the right refrigerant, we can optimize system performance while minimizing environmental impact. As new refrigerants and technologies continue to emerge, we can expect even greater advances in the world of refrigerant vapor density.