Ever wondered how the vapor dome refrigeration cycle keeps things cool? Let’s dive into this fascinating technology to understand how it works, its history, and its impact on the environment.

Table of Contents

Definition

So, what is the vapor dome refrigeration cycle? In simple terms, it’s a cooling process that uses the evaporation and condensation of a refrigerant to transfer heat. The purpose? To keep your ice cream frozen and your office at the perfect temperature.

Basic Concept

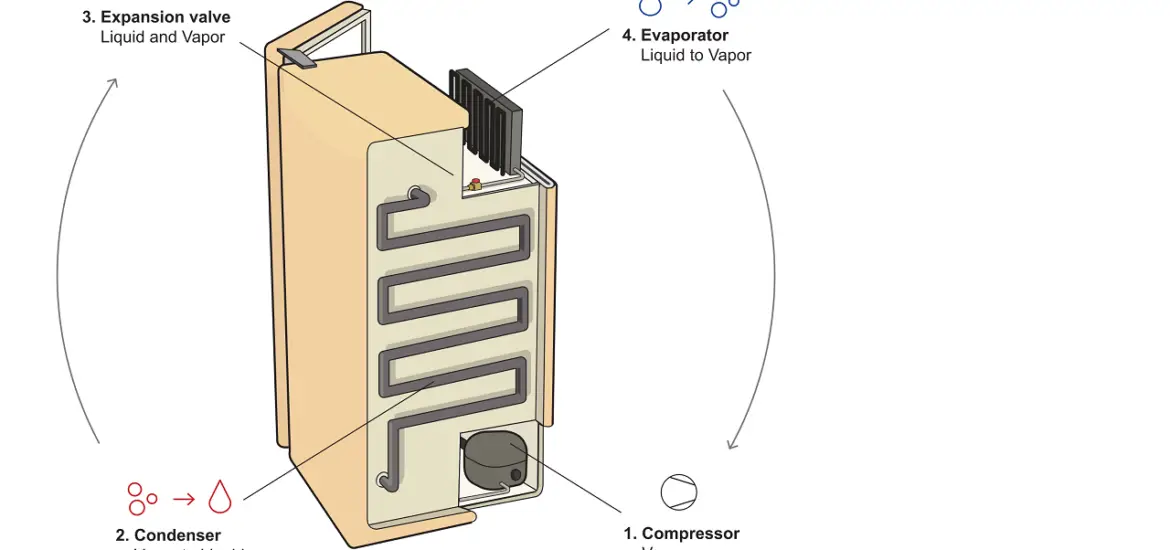

The basic concept of the vapor dome refrigeration cycle is based on the evaporation and condensation of a refrigerant within a closed loop. This loop has four main components: an evaporator, a compressor, a condenser, and an expansion device. Together, they create a cycle that efficiently cools down spaces and maintains desired temperatures.

Purpose

Why do we need vapor dome refrigeration? It’s simple: we need to control temperatures in various settings, from industrial processes to our homes and cars. It’s a technology that has transformed our lives, making it more comfortable and efficient.

Historical Context

Let’s travel back in time to see where it all began.

Early Refrigeration Systems

Before vapor dome technology, early refrigeration systems relied on ice or cooled air to maintain low temperatures. It was a cumbersome and inefficient process, but it paved the way for modern refrigeration.

Emergence of Vapor Dome Technology

The vapor dome refrigeration cycle was born out of necessity in the early 20th century. Engineers sought more efficient cooling methods, leading to the development of vapor compression refrigeration systems. And it’s been evolving ever since!

Read our other vapor refrigeration articles – Vapor Refrigeration: Easy Guide to Keeping Things Chill

Applications

Where can you find vapor dome refrigeration at work?

Industrial Refrigeration

Industrial settings like food processing plants and chemical factories depend on the vapor dome refrigeration cycle to maintain precise temperatures for product quality and safety. It’s the backbone of these industries!

Air Conditioning

Your home or office’s air conditioning system likely uses vapor dome refrigeration to keep you cool during hot summer days. It’s a technology that’s hard to live without!

Basic Components of Vapor Dome Refrigeration Cycle

Now, let’s break down the four main components of this fascinating cycle.

Evaporator

The evaporator is the heart of the system, where heat is absorbed from the surrounding environment.

Function

The evaporator absorbs heat from the space to be cooled, causing the refrigerant inside to evaporate. This phase change transforms the refrigerant from a low-pressure liquid into a low-pressure vapor.

There are several types of evaporators used in vapor dome refrigeration systems, such as plate, shell and tube, and finned tube evaporators. Each has its own advantages and applications, but they all serve the same purpose: to absorb heat and initiate the refrigeration cycle.

Compressor

The compressor is the muscle of the system, giving the refrigerant a push.

Function

The compressor’s job is to increase the pressure of the refrigerant vapor, raising its temperature in the process. This high-pressure, high-temperature vapor then moves on to the condenser.

Types

There are different types of compressors, such as reciprocating, scroll, screw, and centrifugal compressors. Each type has its unique features, but all serve to compress the refrigerant vapor and increase its pressure.

Condenser

The condenser is the cooling superstar, rejecting heat back into the environment.

Function

In the condenser, the high-pressure refrigerant vapor releases its heat, usually to the surrounding air or water. This process causes the refrigerant to condense back into a high-pressure liquid, ready to continue the cycle.

Types

Condensers come in different designs, such as air-cooled, water-cooled, and evaporative condensers. Each type has its unique way of dissipating heat, but all have the same goal: to remove heat from the refrigerant and transform it back into a liquid.

Expansion Device

The expansion device is the gatekeeper, controlling the flow of refrigerant into the evaporator.

Function

The expansion device lowers the pressure of the high-pressure liquid refrigerant, causing its temperature to drop. This cold, low-pressure liquid then enters the evaporator, ready to absorb heat and start the cycle anew.

Types

There are several types of expansion devices, such as thermostatic expansion valves, capillary tubes, and electronic expansion valves. Each type controls the flow of refrigerant differently, but all serve the same purpose: to reduce the refrigerant’s pressure and temperature before it enters the evaporator.

Thermodynamic Processes

Now let’s explore the four main processes that occur within the vapor dome refrigeration cycle.

Evaporation

Evaporation is where the magic happens, and heat is absorbed from the environment.

Heat Absorption

When the low-pressure liquid refrigerant enters the evaporator, it absorbs heat from the surrounding space. This heat absorption causes the refrigerant to evaporate, turning it into a vapor.

Refrigerant Phase Change

As the refrigerant absorbs heat and evaporates, it undergoes a phase change from liquid to vapor. This phase change is crucial for the efficient transfer of heat within the vapor dome refrigeration cycle.

Compression

Compression is the process of increasing the refrigerant’s pressure and temperature.

Refrigerant Pressure Increase

The compressor increases the pressure of the refrigerant vapor, pushing it through the system. This pressure increase is necessary for the refrigerant to release its heat effectively in the condenser.

Temperature Rise

As the refrigerant vapor’s pressure increases, so does its temperature. This high-temperature vapor is now ready to move on to the condenser, where it will release its heat.

Condensation

Condensation is the process of releasing heat and transforming the refrigerant vapor back into a liquid.

Heat Rejection

When the high-pressure, high-temperature refrigerant vapor enters the condenser, it releases its heat to the surrounding air or water. This heat rejection is an essential part of the cooling process.

Refrigerant Phase Change

As the refrigerant releases heat in the condenser, it undergoes another phase change, condensing back into a liquid. This high-pressure liquid is now ready to pass through the expansion device and start the cycle anew.

Expansion

Expansion is the final step in the vapor dome refrigeration cycle, preparing the refrigerant for re-entry into the evaporator.

Refrigerant Pressure Decrease

The expansion device reduces the pressure of the high-pressure liquid refrigerant, allowing it to enter the evaporator at a lower pressure and temperature. This pressure decrease is crucial for the refrigerant to effectively absorb heat in the evaporator.

Temperature Drop

As the refrigerant pressure decreases, so does its temperature. This cold, low-pressure liquid refrigerant is now ready to absorb heat in the evaporator and initiate the cycle again.

Vapor Dome Phenomenon

What’s the deal with the “vapor dome” in the vapor dome refrigeration cycle?

Definition

The vapor dome is a term used to describe the region in a refrigeration system where both liquid and vapor refrigerant coexist. It plays a crucial role in the refrigeration cycle, allowing for efficient heat transfer and phase changes.

Role in Refrigeration Cycle

The vapor dome phenomenon occurs within the evaporator and condenser, where the refrigerant undergoes phase changes from liquid to vapor and back again. These phase changes are essential for the effective transfer of heat within the vapor dome refrigeration cycle.

Thermodynamic Saturation Properties

Let’s dive into the science behind the vapor dome.

Pressure-temperature Relationship

Within the vapor dome, there’s a unique relationship between pressure and temperature. At any given pressure, there’s a specific temperature at which the refrigerant will change phases. This relationship is critical to the efficient functioning of the vapor dome refrigeration cycle.

Saturation Curve

The saturation curve represents the pressure-temperature relationship within the vapor dome. It’s an essential tool for understanding and optimizing the performance of vapor dome refrigeration systems.

Subcooling and Superheating

Subcooling and superheating are two important concepts related to the vapor dome refrigeration cycle. They help ensure the system’s efficiency and stability.

Definition

Subcooling is the process of cooling the refrigerant liquid below its saturation temperature at a given pressure, while superheating refers to heating the refrigerant vapor above its saturation temperature. These processes help optimize system performance and avoid issues such as liquid refrigerant entering the compressor.

Effects on System Performance

Subcooling and superheating play a crucial role in improving the performance of vapor dome refrigeration systems. By ensuring proper phase changes and heat transfer, they help increase efficiency, reduce energy consumption, and prevent system malfunctions.

Performance Parameters

Now, let’s discuss some key performance parameters for vapor dome refrigeration systems.

Coefficient of Performance (COP)

The COP is a measure of how efficiently a refrigeration system operates.

Definition

The Coefficient of Performance (COP) is the ratio of the cooling capacity of a refrigeration system to the amount of work input, typically in the form of electrical energy. A higher COP indicates a more efficient system.

Factors Affecting COP

Several factors can affect the COP of a vapor dome refrigeration system, such as the type of refrigerant used, the design of system components, and the operating conditions. By optimizing these factors, it’s possible to improve system efficiency and reduce energy consumption.

Refrigeration Capacity

Refrigeration capacity is a measure of a system’s ability to remove heat.

Definition

The refrigeration capacity is the amount of heat a refrigeration system can remove from a space per unit of time, usually expressed in BTUs per hour or Watts. The capacity is a critical parameter in selecting the right system for a specific application.

Factors Affecting Capacity

Factors such as the type of refrigerant, system design, and operating conditions can impact the refrigeration capacity of a vapor dome refrigeration system. By carefully considering these factors, it’s possible to design a system that meets the cooling requirements of a specific application.

Efficiency

Efficiency is a measure of how well a refrigeration system converts input energy into cooling.

Definition

Efficiency in a vapor dome refrigeration system refers to the ratio of the system’s cooling capacity to the amount of energy input required to achieve that capacity. Higher efficiency means that the system uses less energy to provide the same amount of cooling.

Factors Affecting Efficiency

Various factors, such as refrigerant type, system design, and operating conditions, can influence the efficiency of a vapor dome refrigeration system. By optimizing these factors, system efficiency can be improved, reducing energy consumption and environmental impact.

Environmental Impact and Regulations

Let’s explore the environmental impact of vapor dome refrigeration systems and the regulations governing their use.

Refrigerants

Refrigerants are a critical component of vapor dome refrigeration systems, but some have significant environmental consequences.

Environmental Concerns

Some refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been found to be harmful to the environment due to their ozone depletion potential (ODP) and global warming potential (GWP). As a result, there has been a push towards using more environmentally friendly refrigerants like hydrofluorocarbons (HFCs) and natural refrigerants (e.g., ammonia, carbon dioxide, and hydrocarbons).

Ozone Depletion Potential (ODP)

ODP is a measure of a substance’s ability to deplete the Earth’s ozone layer. Refrigerants with high ODP contribute to the destruction of the ozone layer, increasing the risk of harmful ultraviolet (UV) radiation reaching the Earth’s surface. Regulations have been implemented to phase out refrigerants with high ODP.

Global Warming Potential (GWP)

GWP is a measure of how much heat a substance can trap in the atmosphere over a specific period, contributing to the greenhouse effect and global warming. Refrigerants with high GWP contribute to climate change, and regulations have been implemented to limit their use and encourage the adoption of low-GWP alternatives.

Energy Consumption

The energy consumption of vapor dome refrigeration systems has a direct impact on climate change.

Impact on Climate Change

Energy consumption contributes to climate change through the production of greenhouse gases, such as carbon dioxide, during the generation of electricity. By improving the efficiency of vapor dome refrigeration systems, energy consumption can be reduced, decreasing their environmental impact.

Regulations and Standards

Regulations and standards govern the use and environmental impact of vapor dome refrigeration systems.

International Agreements

International agreements, such as the Montreal Protocol and the Kigali Amendment, have been established to phase out ozone-depleting substances and reduce the use of high-GWP refrigerants. These agreements have driven the development and adoption of more environmentally friendly refrigeration technologies.

Local Regulations

Local regulations and standards also play a role in governing the use of refrigerants, the efficiency of vapor dome refrigeration systems, and their environmental impact. These regulations vary by country and region but are generally focused on minimizing the environmental impact of refrigeration systems.

Future Trends and Innovations

Now, let’s look at some future trends and innovations in the world of vapor dome refrigeration systems.

Alternative Refrigeration Technologies

New, innovative refrigeration technologies are being developed as alternatives to traditional vapor dome refrigeration systems.

Magnetic Refrigeration

Magnetic refrigeration is an emerging technology that uses magnetic fields and magnetocaloric materials to provide cooling. This technology is highly efficient and environmentally friendly, with the potential to revolutionize the refrigeration industry.

Thermoacoustic Refrigeration

Thermoacoustic refrigeration uses sound waves to generate cooling, eliminating the need for traditional refrigerants. This technology is still in the research and development stage but holds great promise for a more sustainable future in refrigeration.

Energy Efficiency Improvements

Improving energy efficiency is a key focus for the future of vapor dome refrigeration systems.

Waste Heat Recovery

Waste heat recovery technologies can capture and reuse the heat generated by vapor dome refrigeration systems, improving overall energy efficiency. This waste heat can be used for various purposes, such as heating water, space heating, or even powering other processes, reducing energy consumption and environmental impact.

Advanced Control Systems

Advanced control systems can optimize the performance of vapor dome refrigeration systems, adjusting variables like refrigerant flow, compressor speed, and fan operation in real-time. These control systems can significantly improve energy efficiency, reduce operating costs, and minimize environmental impact.