Ever wondered how to make your home’s HVAC system even more efficient? Enter the refrigeration suction line heat exchanger! Let’s dive in and explore what these devices are and how they can benefit you as a homeowner.

Table of Contents

Definition and Purpose of Refrigeration Suction Line Heat Exchangers

What is a suction line heat exchanger?

A suction line heat exchanger is a device used in HVAC systems to improve efficiency by transferring heat between the refrigerant lines. Sounds cool, right? It helps save energy and money in the long run.

Benefits of using a suction line heat exchanger

So, why should you care? These nifty gadgets have some great benefits like:

- Increased system efficiency

- Reduced energy consumption

- Lower energy bills

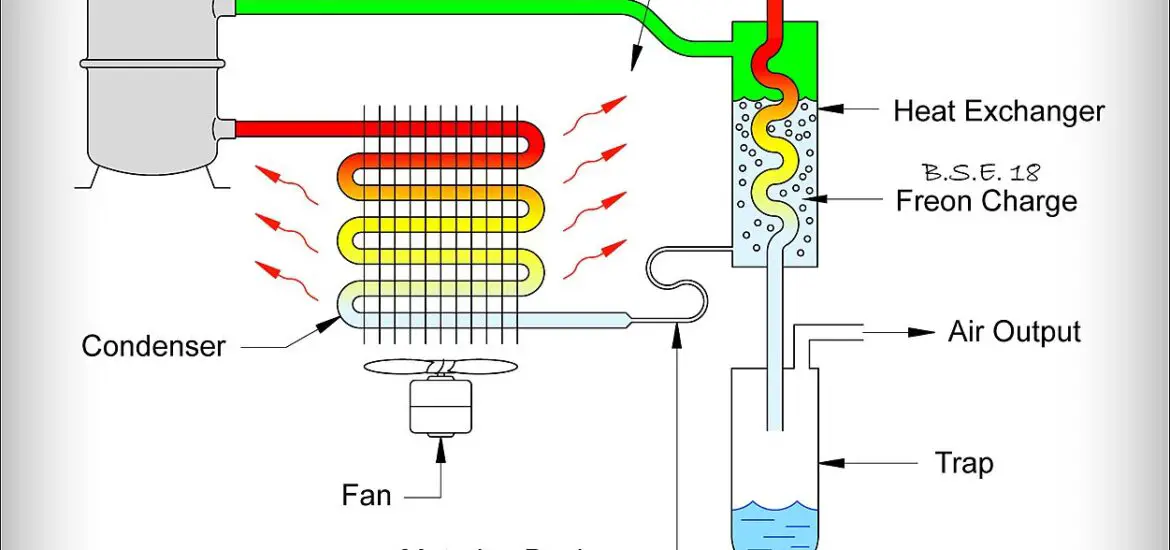

Components of a Refrigeration System

Before we dive deeper, let’s get to know the main components of a refrigeration system:

Compressor

The compressor is the heart of the system, pumping refrigerant throughout.

Condenser

Think of the condenser as a hot-headed device that releases heat from the refrigerant.

Expansion Device

The expansion device is the gatekeeper, controlling refrigerant flow between the high and low-pressure sides of the system.

Evaporator

The evaporator is like a sponge, absorbing heat from the surrounding air to cool your home.

Suction Line

Lastly, the suction line is the refrigerant’s highway back to the compressor for another cooling cycle.

Types of Suction Line Heat Exchangers

There are different types of suction line heat exchangers, each with its pros and cons. Let’s take a look:

Shell and Tube Heat Exchangers

Construction

Imagine a bunch of small tubes inside a larger shell. That’s the basic structure of a shell and tube heat exchanger.

Advantages and Disadvantages

These are great for high-pressure applications, but they can be bulky and expensive.

Plate Heat Exchangers

Construction

Picture a stack of metal plates with grooves for refrigerant flow. That’s a plate heat exchanger for you!

Advantages and Disadvantages

These are compact and efficient, but they might not be the best choice for high-pressure applications.

Coaxial Heat Exchangers

Construction

A tube within a tube – that’s the essence of a coaxial heat exchanger.

Advantages and Disadvantages

Coaxial heat exchangers are compact and work well in residential systems, but they might not be suitable for larger applications.

Coaxial heat exchangers are compact and work well in residential systems, but they might not be suitable for larger applications.

Design Considerations for Suction Line Heat Exchangers

When choosing a suction line heat exchanger, there are a few factors to consider:

Heat Transfer Rate

Factors Affecting Heat Transfer Rate

Things like surface area, temperature difference, and refrigerant properties can impact heat transfer rate. You’ll want a heat exchanger that’s efficient without being too large or costly.

Material Selection

Commonly Used Materials

Materials like copper, aluminum, and stainless steel are common choices for heat exchangers. But which one is best for your home? It depends on factors like corrosion resistance, cost, and heat transfer efficiency.

Material Properties

Some materials might be better conductors of heat, while others might be more resistant to corrosion. Make sure you’re choosing a material that’s best suited for your system’s needs.

Pressure Drop

Calculating Pressure Drop

Pressure drop is the decrease in pressure as the refrigerant flows through the heat exchanger. You’ll want to choose a heat exchanger that minimizes pressure drop to maintain system efficiency.

Impact on System Efficiency

Remember, a high pressure drop can reduce system efficiency, leading to increased energy consumption and higher bills. It’s essential to find a balance between pressure drop and heat transfer efficiency.

Fouling

Causes and Consequences

Over time, dirt and debris can accumulate on the heat exchanger surfaces, reducing its efficiency. This is called fouling, and it can lead to increased energy consumption and even system failure.

Preventive Measures

Regular maintenance, like cleaning and inspection, can help prevent fouling and keep your heat exchanger running smoothly.

Installation and Maintenance of Suction Line Heat Exchangers

Now that you know what to look for, let’s talk about installation and maintenance:

Installation Guidelines

Positioning

Proper positioning is crucial for optimal performance. Make sure your heat exchanger is installed according to the manufacturer’s recommendations.

Piping and Connections

Ensure that all pipes and connections are secure and leak-free for efficient operation and minimal energy loss.

Safety Considerations

Don’t forget about safety! Follow all local codes and guidelines when installing your heat exchanger.

Maintenance Procedures

Regular Inspection

Inspect your heat exchanger regularly for signs of wear, corrosion, or fouling. It’s easier to fix small issues before they become big problems!

Cleaning

Keep your heat exchanger clean and free of debris to ensure optimal performance and efficiency.

Component Replacement

If you notice any damaged or worn components, replace them promptly to maintain your system’s efficiency.

Applications of Suction Line Heat Exchangers

So, where can you find these handy devices? Here are a few examples:

Residential HVAC Systems

Benefits for Homeowners

As a homeowner, a suction line heat exchanger can help you save energy and money by

Chimezirim Odimba

Continue from

Benefits for Homeowners

As a homeowner, a suction line heat exchanger can help you save energy and money by increasing the efficiency of your HVAC system. With lower energy consumption and reduced maintenance costs, it’s a win-win situation!

Commercial Refrigeration Systems

Supermarket Refrigeration

Supermarkets rely heavily on refrigeration to keep perishable goods fresh. Suction line heat exchangers can help these large systems run more efficiently, saving businesses money and reducing their environmental impact.

Cold Storage Facilities

From warehouses to food processing plants, cold storage facilities can also benefit from the energy-saving advantages of suction line heat exchangers. These large-scale operations can save big bucks by investing in efficient technology.

Industrial Refrigeration Systems

Process Cooling

Many industries require process cooling, and suction line heat exchangers can help improve efficiency and reduce energy consumption in these applications as well.

Food and Beverage Industry

From breweries to dairies, the food and beverage industry relies heavily on refrigeration. Suction line heat exchangers can play a crucial role in maintaining product quality while minimizing energy costs.

Conclusion

Summary of Key Points

In conclusion, refrigeration suction line heat exchangers are valuable devices that can help homeowners, businesses, and industries save energy and money. By increasing efficiency and reducing maintenance costs, these heat exchangers are a smart investment for any HVAC or refrigeration system.

Future Developments in Suction Line Heat Exchangers

As technology continues to advance, we can expect even more efficient and cost-effective suction line heat exchangers to hit the market. So, keep an eye out for new innovations and stay ahead of the curve in energy savings!