Subcooling in refrigeration—ever heard of it? It’s that critical process that helps your fridge stay cool and efficient. If you’re a homeowner, understanding subcooling could save you money and keep your refrigeration systems running smoothly. So, let’s dive right into the nitty-gritty of subcooling and why it’s so important.

Table of Contents

Understanding the Concept of Subcooling

Basic Definition of Subcooling

Subcooling is the process of cooling liquid refrigerant below its saturation temperature. In other words, it’s the extra cooling that happens after the refrigerant has turned from a gas into a liquid.

Importance of Subcooling in a Refrigeration Cycle

Why should you care about subcooling? Well, proper subcooling helps your refrigeration system work more efficiently, saving energy and ensuring optimal performance. It also prevents liquid refrigerant from returning to the compressor—a big no-no in the world of refrigeration.

Subcooling of Refrigerant

How Subcooling is Achieved

Methods for Subcooling Refrigerant

There are several ways to achieve subcooling, such as using a heat exchanger, water-cooled condensers, or simply increasing the size of the condenser coil. Each method has its pros and cons, depending on your refrigeration system and needs.

Factors Affecting the Degree of Subcooling

How much subcooling is needed? That depends on factors like ambient temperature, refrigerant type, and system load. It’s essential to get the right amount of subcooling for your specific system to maximize efficiency and prevent issues.

Subcooling Temperature

Measuring Subcooling Temperature

Required Tools and Equipment

To measure subcooling, you’ll need a thermometer and a pressure gauge. A digital manifold gauge set is a popular tool for HVAC technicians, but even a simple thermometer and pressure gauge combo will do the trick.

Calculating Subcooling Temperature

Here’s the formula for calculating subcooling: actual liquid line temperature minus saturation temperature. It’s essential to check the manufacturer’s guidelines for the correct subcooling temperature range for your system.

Optimal Subcooling Temperature Range

Factors Affecting Optimal Temperature Range

The ideal subcooling temperature range varies based on factors like refrigerant type, system design, and operating conditions. Always refer to your system’s manufacturer guidelines to ensure proper subcooling.

Consequences of Insufficient or Excessive Subcooling Temperature

Too little or too much subcooling? That’s bad news. Insufficient subcooling can lead to poor system performance, while excessive subcooling wastes energy and may even cause system damage. Finding the sweet spot is crucial.

Subcooling in the Refrigeration Cycle

Role of Subcooling in the Refrigeration Cycle

Improving System Efficiency

Proper subcooling plays a big role in improving the efficiency of your refrigeration system. When the refrigerant is adequately subcooled, the system can effectively remove heat, reducing energy consumption and keeping your electricity bills in check.

Preventing Liquid Refrigerant Return

Subcooling also helps prevent liquid refrigerant from returning to the compressor. This is important because liquid refrigerant in the compressor can cause damage, leading to costly repairs or even a complete system breakdown.

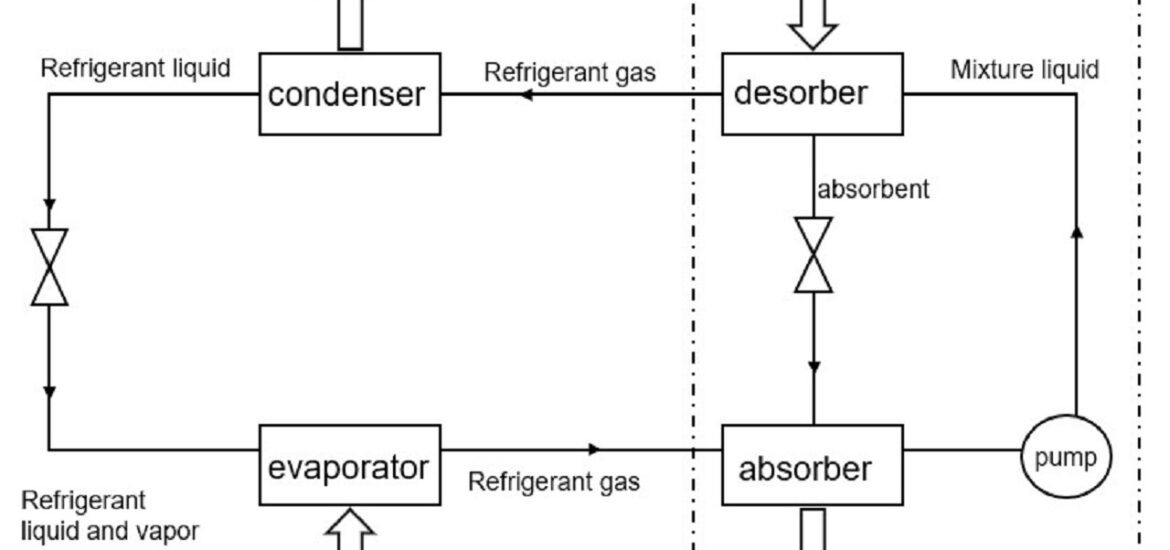

Components Involved in Subcooling

Condenser and its Role in Subcooling

The condenser plays a vital role in subcooling, as it’s where the refrigerant gas turns into a liquid. By increasing the condenser’s surface area or using a water-cooled condenser, you can achieve more efficient subcooling.

Expansion Valve and its Effect on Subcooling

The expansion valve is another critical component in subcooling. It controls the flow of refrigerant into the evaporator, ensuring that the right amount of refrigerant is available for heat transfer. A properly functioning expansion valve is essential for achieving optimal subcooling.

Subcooling Meaning and Definition in Refrigeration

Clarifying the Term “subcooling”

Common Misconceptions

One common misconception is that subcooling and superheating are the same thing. Nope! While both terms deal with refrigerant temperatures, subcooling refers to the cooling of liquid refrigerant below its saturation point, while superheating pertains to heating the refrigerant vapor above its saturation point.

Relation to other Refrigeration Terms

Subcooling is just one piece of the refrigeration puzzle. It’s closely related to other concepts like the refrigeration cycle, compression, condensation, evaporation, and expansion. Understanding how all these concepts fit together can help you better grasp the intricacies of refrigeration.

What Does Subcooling Mean in Practical Applications

Importance of Proper Subcooling in Real-world Scenarios

Impacts on System Performance

Getting subcooling right is crucial for optimal system performance. Inadequate subcooling can lead to reduced cooling capacity and increased energy consumption, while excessive subcooling can cause the compressor to work harder, shortening its lifespan.

Implications for Maintenance and Troubleshooting

Understanding subcooling can also help you diagnose and troubleshoot refrigeration system issues. If you notice your system isn’t performing as it should, checking the subcooling temperature can provide valuable clues to the underlying problem.

Subcooling in Various Refrigeration Systems

Subcooling in Commercial Refrigeration Systems

Importance of subcooling for Energy Efficiency

In commercial settings, energy efficiency is key to reducing operating costs. Proper subcooling helps commercial refrigeration systems work more efficiently, cutting energy consumption and saving money in the long run.

Specific Challenges and Solutions in Commercial Systems

Commercial refrigeration systems often face unique challenges, such as higher cooling loads and more frequent door openings. Implementing proper subcooling techniques can help address these challenges and ensure optimal performance.

Subcooling in Industrial Refrigeration Systems

Unique Requirements for Subcooling in Industrial Settings

Industrial refrigeration systems often have specific requirements for subcooling, depending on factors like process cooling needs and production demands. Customized subcooling solutions are often necessary to meet these unique needs and ensure efficient operation.

System Design Considerations for Optimal Subcooling

Designing industrial refrigeration systems with optimal subcooling in mind is crucial. This may involve selecting the right condenser size, choosing the appropriate refrigerant, and installing advanced control systems to monitor and adjust subcooling levels.

Subcooling in Residential Refrigeration Systems

Best Practices for Homeowners and Technicians

Homeowners and technicians should be familiar with the subcooling requirements of residential refrigeration systems. Regular maintenance, such as cleaning condenser coils and checking refrigerant levels, can help ensure proper subcooling and efficient system operation.

Troubleshooting Subcooling Issues in Residential Systems

If you’re experiencing issues with your home’s refrigeration system, understanding subcooling can help with troubleshooting. Issues like high energy bills, poor cooling performance, or a noisy compressor could all be related to subcooling problems.

Subcooling in Modern Refrigeration Technologies

Innovative Approaches to Subcooling

Recent Advancements in Subcooling Technology

Advancements in subcooling technology are making refrigeration systems more efficient and eco-friendly. Some recent innovations include advanced heat exchangers, variable-speed compressors, and smart control systems that adjust subcooling based on real-time system data.

Emerging Trends in Refrigeration System Design

As the world moves towards greener technologies, modern refrigeration system designs are focusing on energy efficiency and environmental impact. Optimizing subcooling is a crucial part of these efforts, helping to reduce energy consumption and greenhouse gas emissions.

Smart Refrigeration Systems and Subcooling Control

Integration of IoT devices and Sensors for subcooling Management

Internet of Things (IoT) devices and sensors are increasingly being used to manage subcooling in refrigeration systems. These smart technologies can monitor subcooling levels in real-time, allowing for more precise control and improved efficiency.

Benefits of Data-driven Subcooling Optimization

Data-driven subcooling optimization can help identify inefficiencies, reduce energy consumption, and extend the lifespan of refrigeration system components. This not only saves money but also contributes to a greener future for our planet.

Environmental Considerations in Subcooling

Subcooling and Refrigerant Choice

Impact of Refrigerant Types on Subcooling Performance

Different refrigerants have different subcooling requirements, which can impact system performance and efficiency. It’s essential to select the right refrigerant for your system, considering factors like environmental impact and local regulations.

Environmental Regulations Affecting Refrigerant Selection

As global efforts to combat climate change intensify, regulations surrounding refrigerant selection are becoming more stringent. Choosing environmentally friendly refrigerants and optimizing subcooling can help reduce the environmental impact of refrigeration systems.

Energy Efficiency and Subcooling Optimization

Strategies for Reducing Energy Consumption

Optimizing subcooling is a key strategy for reducing energy consumption in refrigeration systems. Other tactics include regular maintenance, proper insulation, and investing in energy-efficient equipment, all of which contribute to a more sustainable future.

The Role of Subcooling in Green Refrigeration Technologies

Green refrigeration technologies aim to minimize the environmental impact of cooling systems. Subcooling plays a significant role in these efforts, as optimized subcooling contributes to reduced energy consumption, lower greenhouse gas emissions, and a smaller overall carbon footprint.

Conclusion

The Importance of Understanding Subcooling

Implications for System Design, Operation, and Maintenance

Understanding subcooling is crucial for homeowners and professionals alike, as it affects system design, operation, and maintenance. Proper subcooling helps ensure efficient performance, reduced energy consumption, and a longer lifespan for your refrigeration system.

Future Outlook on Subcooling and Refrigeration Technologies

As technology continues to evolve, we can expect new advancements in subcooling and refrigeration systems that further improve efficiency and reduce environmental impact. By staying informed about subcooling, you’ll be well-equipped to make smart choices about your refrigeration system—now and in the future.