In this article, we’ll explain in detail why boiling point of refrigerant should be low. Understanding this principle is key to realizing how your refrigerator keeps your food cool and your A/C keeps you from melting on a scorching summer day.

Table of Contents

Overview: The Importance of a Low Boiling Point for Refrigerants

Let’s keep things straightforward. A refrigerant with a low boiling point is like a marathon runner with a swift pace. It ensures efficient cooling systems, doing the hard work so you don’t have to.

The Basic Principles of Refrigeration

Refrigeration isn’t a magic trick, but the science behind it might seem like it. It’s all about managing heat transfer and phase changes, with refrigerants taking the starring role in this cool performance.

Understanding Phase Changes

Imagine you’re heating a pot of water on a stove. It starts as a liquid, then turns to steam – that’s a phase change. It’s a superhero-like transformation that substances undergo between solid, liquid, and gas stages. In refrigeration, we’re particularly interested in evaporation (liquid to gas) and condensation (gas to liquid).

The Role of the Refrigerant in the Refrigeration Cycle

So where does our star player, the refrigerant, come in? It’s the all-star that performs these phase changes, absorbing heat when it evaporates and releasing it when it condenses. It’s the champion of the cooling world, bouncing back and forth between these two phases, just like a swing set in motion.

Why the Boiling Point Matters

The boiling point is like the heart of refrigeration. It determines how effectively a refrigerant can convert from liquid to gas and vice versa, affecting everything from energy efficiency to cooling ability. It’s the key to understanding why refrigerants do what they do.

What is Boiling Point?

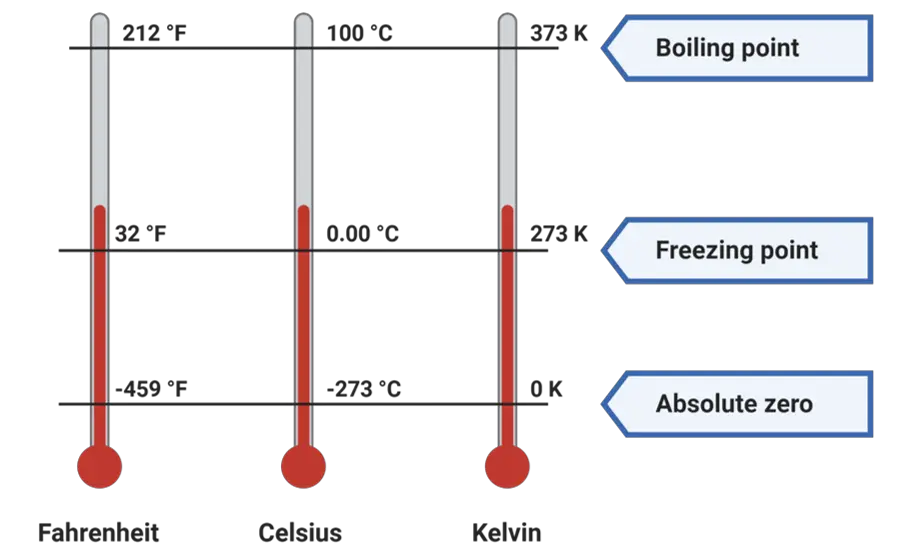

The boiling point is like the tipping point on a seesaw. It’s the temperature at which a liquid starts to boil and turns into a gas. Every substance has a different boiling point, like unique fingerprints.

The Relationship Between Boiling Point and Pressure

Think of boiling point and pressure as dance partners. They move in sync. When the pressure goes up, the boiling point follows suit. And when the pressure drops, the boiling point drops too.

Why Boiling Point of Refrigerant Should Be Low

Why should a refrigerant have a low boiling point? The key is in how fast the refrigerant can boil and change from a liquid to a gas, absorbing heat in the process. It’s the quick-change artist of the refrigeration world.

Implications of a High Boiling Point in Refrigerants

Using a refrigerant with a high boiling point? It’s like running a race with ankle weights. It can lead to energy inefficiency, insufficient cooling, and potentially damage your cooling systems. Not the best game plan for a cool, comfortable space, right?

Energy Inefficiency

A refrigerant with a high boiling point is like a car with a flat tire. It takes more energy to get it moving, and even then, it doesn’t go very fast. This extra energy usage can be a drain on your wallet and on the environment.

Insufficient Cooling

With a high boiling point, a refrigerant is like a sluggish snail on a hot day. It takes longer to absorb heat and can struggle to provide the cool relief your system is designed to deliver.

Potential Equipment Damage

Like forcing a square peg into a round hole, using a refrigerant with a high boiling point can put undue stress on your system, potentially leading to premature equipment failure. Who wants to deal with that?

Check out these other related articles…

Top Up Refrigerant Gas: Your Ultimate Guide for Cooling Efficiency

Refrigerant Orifice: Your Key to Understanding and Mastering Refrigeration

Reclaiming Refrigerant: Your Complete Guide

Best Refrigerant for Low-Temperature Applications: A Comprehensive Guide

Boiling Point of Refrigerants: A Comprehensive Examination

Properties of a Refrigerant: Your Quick 411 Guide

Types of Refrigerant Used in Refrigeration Systems: Revealed

Benefits of a Low Boiling Point in Refrigerants

So, why should we care about a low boiling point in refrigerants? It’s all about efficiency and longevity, like an athlete at the top of their game.

Energy Efficiency

Imagine a refrigerator with a low boiling point as a well-tuned race car. It’s not wasting energy. It’s efficient, helping you to save on electricity costs. That’s a refrigerant with a low boiling point for you.

Optimal Cooling

Picture a refrigerant with a low boiling point like a quick-change artist. It easily swaps from liquid to gas, absorbing and dumping heat like a champ. It’s all about keeping you cool when the heat is on.

Prolonged Equipment Lifespan

Think about it this way – a refrigerant with a low boiling point treats your cooling systems right, like a regular spa day for your refrigerator or air conditioner. It keeps them running smoothly for longer, saving you from costly repairs or early replacement.

Common Low Boiling Point Refrigerants

Now that we’ve sorted out why a low boiling point is so crucial, let’s meet some of the key players in the refrigerant game.

Ammonia

Ammonia, also known by its stage name NH3, has a boiling point of -33.34 degrees Celsius. It’s been in the refrigeration game for ages, used in industrial and food storage applications. While it’s not without its challenges, it’s a reliable performer in the right setting.

Carbon Dioxide

Carbon dioxide or CO2 isn’t just for fizzy drinks. With a boiling point of -78.5 degrees Celsius, it’s made a comeback in refrigeration, especially in systems designed for colder climates. CO2 is like the comeback kid of refrigerants.

Hydrofluorocarbons (HFCs)

These are the new kids on the refrigerant block. There’s a range of HFCs out there, each with different boiling points, but all generally lower than traditional refrigerants. They’re like the new generation, promising less environmental impact while delivering solid performance.