Mixed refrigerant compressor is a term that’s been buzzing around in the HVAC industry. But what does it really mean? Why is it significant? Stick around as we explore these intriguing questions and more.

Table of Contents

Understanding Mixed Refrigerant Systems

Let’s hit the road by gaining some insight into mixed refrigerant systems.

Definition and Functionality

At their core, refrigeration systems absorb heat from a low-temperature region and discard it to a higher-temperature region. How cool is that, right? And don’t worry, we’ll break it down even further.

Understanding Refrigeration Cycle

Picture this: a cycling process involving evaporation, compression, condensation, and expansion. That’s the refrigeration cycle for you. Simple, yet profoundly effective.

Role of Compressors in the Refrigeration Cycle

Imagine the compressor as the heart of the refrigeration cycle, pumping the refrigerant around the system. Without it, the cycle would come to a standstill.

What is a Mixed Refrigerant?

A mixed refrigerant is just a blend of different refrigerants. Think of it as a cocktail of refrigerants, each with its distinct properties.

Importance of Mixing Refrigerants

Why mix refrigerants, you ask? Simple. It allows us to create custom properties to meet specific refrigeration needs. It’s like customizing your own coffee blend. Tasty, right?

Examples of Common Refrigerant Mixtures

Just as there are countless coffee blends, there are numerous refrigerant mixtures. One popular blend is R-410A, used in residential and light commercial HVAC systems. Now, that’s quite versatile, isn’t it?

The Concept of Mixed Refrigerant Compressor

Enter the mixed refrigerant compressor: an ingenious piece of tech that compresses mixed refrigerants. Let’s delve a bit more.

Working Principle

These compressors work in a similar fashion to your regular compressor but are specially designed to handle mixed refrigerants. Just like how a barista would have special skills for different coffee blends.

Applications of Mixed Refrigerant Compressors

Mixed refrigerant compressors are used in various areas, from residential cooling systems to industrial refrigeration. Their versatility is comparable to a Swiss Army knife, wouldn’t you agree?

Types of Mixed Refrigerant Compressors

Did you know there are several types of these compressors? Let’s explore.

Reciprocating Compressors

The reciprocating compressor is a classic, like an old favorite book on your shelf. Let’s find out why.

Design and Working Principle

Imagine a piston moving back and forth in a cylinder – that’s the basic idea behind a reciprocating compressor. It’s as rhythmic as a heart beat.

Pros and Cons

While these compressors are durable and efficient, they’re not the quietest bunch. That’s just like a classic old car – they’ve got power but they’re not exactly whisper-quiet.

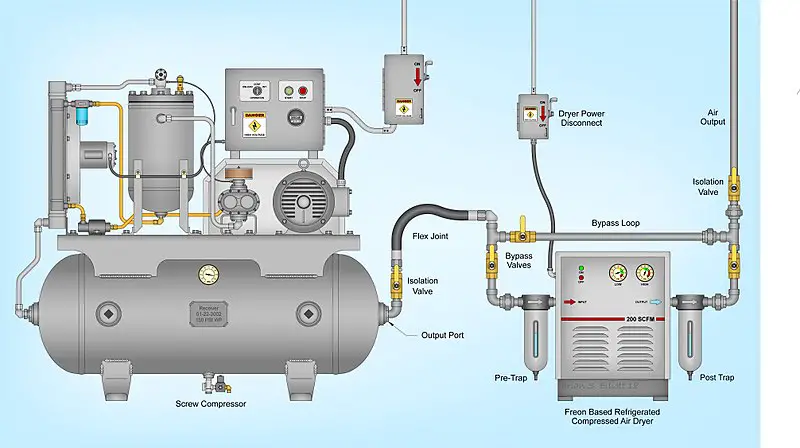

Rotary Screw Compressors

Next up is the rotary screw compressor. Think of it as the modern, silent type.

Design and Working Principle

In this design, two rotors interlock like gears. The elegance of the process is comparable to a well-choreographed dance.

Pros and Cons

They’re known for their quiet operation and efficiency but maintenance can be a tad complex. It’s a bit like owning a high-end gadget, isn’t it?

Centrifugal Compressors

Lastly, we have the centrifugal compressors. Imagine a high-speed ride at an amusement park – that’s the kind of energy we’re talking about!

Design and Working Principle

These compressors use a rotating impeller to increase the refrigerant’s velocity. The experience is as thrilling as a roller coaster ride!

Pros and Cons

They’re super efficient at high capacities but not so much at lower loads. A bit like a sports car – fantastic on the highway, but in city traffic, not so much.

Design Considerations for Mixed Refrigerant Compressors

When it comes to mixed refrigerant compressors, one size does not fit all. You’ve got to consider a few factors. Let’s uncover them.

Compatibility with the Refrigerant Mixture

Your compressor must be compatible with the refrigerant mixture it’s going to work with. It’s like matching your food with the right wine.

Impact of Different Refrigerants on Compressor Performance

Different refrigerants can affect compressor performance. Imagine wearing running shoes for a formal event – you might still walk, but not quite as gracefully.

Considering Thermodynamic Properties

When choosing a refrigerant mixture, its thermodynamic properties must be considered. It’s like picking the right gear for a camping trip, wouldn’t you say?

Compressor Capacity and Load Conditions

Compressor capacity and load conditions are just as important. It’s like picking the right vehicle for a road trip – you wouldn’t pick a compact car for a cross-country adventure, would you?

Importance of Sizing

Getting the right size of the compressor for the job is crucial. It’s like getting the right size of clothing – too big or too small, and it won’t work as well.

Addressing Load Conditions

Load conditions need to be addressed during design. It’s like packing the right amount of food for a picnic – you don’t want too much or too little.

Energy Efficiency and Power Requirements

Lastly, energy efficiency and power requirements must be considered. It’s like choosing the right fuel for your car to get the best performance.

Importance of Energy Efficiency

Energy efficiency isn’t just good for the environment, it’s good for your wallet too. It’s like turning off lights when you leave the room – it makes sense, doesn’t it?

Managing Power Requirements

Managing power requirements is like managing your time – it’s all about using it wisely to get the most out of it.

Maintenance and Safety of Mixed Refrigerant Compressors

Maintaining your compressor is like maintaining your health – it’s all about regular check-ups and safe practices. Let’s learn more.

Regular Maintenance Practices

Regular maintenance is to a compressor what regular exercise is to our bodies – it keeps them running smoothly.

Why Regular Maintenance is Crucial

Regular maintenance extends the life of the compressor and keeps it running efficiently. It’s like taking your car for regular oil changes – it just makes sense, right?

Key Maintenance Steps

Some key maintenance steps include regular cleaning and checking for leaks. It’s similar to maintaining your home – a little effort goes a long way.

For more articles on refrigerants, click here.

Safety Precautions when Operating Mixed Refrigerant Compressors

Just as you’d follow safety rules when driving, operating a compressor also requires certain precautions.

Risk of Refrigerant Leaks

One potential hazard is refrigerant leaks, which can be harmful if not addressed. It’s a bit like a gas leak at home – you’d want to fix it immediately, wouldn’t you?

Precautions to Prevent Accidents

Some precautions include regular inspections and wearing proper safety gear. It’s like wearing a seatbelt when you drive – it’s a simple step that can prevent big problems.

Conclusion: The Future of Mixed Refrigerant Compressors

What does the future hold for mixed refrigerant compressors? Let’s peer into the crystal ball. From digital controls to energy-efficient designs, the future of mixed refrigerant compressors is as exciting as a sci-fi movie.

New designs are on the horizon, promising greater efficiency and versatility. It’s like the evolution of smartphones – remember when they could only make calls?

Eco-friendly refrigerant mixtures are the future. It’s like switching from fossil fuels to renewable energy – it’s a change we need to make.

Just like the stock market, the compressor market is also subject to dynamics. Some big names in this market include Danfoss, Emerson, and Mitsubishi. It’s like the big leagues of the HVAC world!

Growth drivers include rising demand for energy-efficient systems and eco-friendly refrigerants. The trend seems to be leaning towards a greener and more sustainable future, don’t you think?