Ever wondered how to keep your home cool and comfortable in a cost-effective way? Say hello to shell and tube heat exchanger refrigeration! We’ll dive into what it’s all about, how it works, and why it’s a game-changer for homeowners like you.

Table of Contents

Definition of a Heat Exchanger

First things first, what’s a heat exchanger? In simple terms, it’s a device that transfers heat from one fluid to another without mixing them. Pretty neat, huh? There are various types of heat exchangers, but we’re going to focus on the most popular one for homeowners – the shell and tube heat exchanger.

Shell and Tube Heat Exchanger

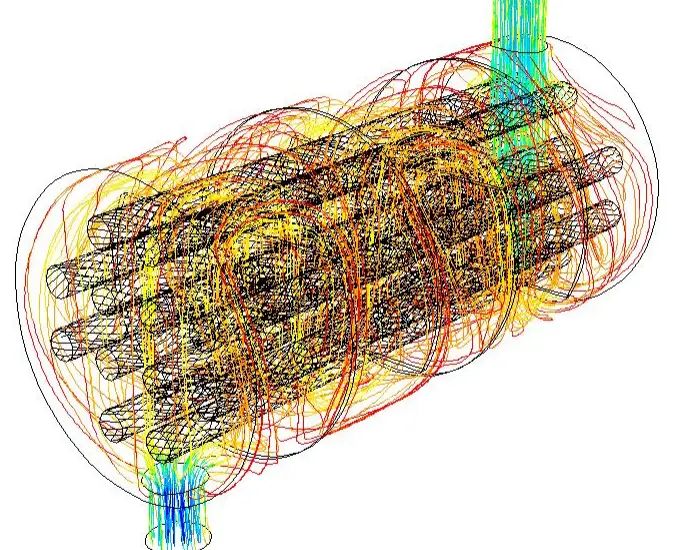

Picture this: a bunch of tubes inside a larger shell. That’s the basic structure of a shell and tube heat exchanger. It works by passing a hot fluid through the tubes and a cold fluid through the shell. The result? The hot fluid cools down while the cold fluid heats up. Sounds like magic, doesn’t it?

These heat exchangers come with a lot of advantages, like being super versatile, but they also have some drawbacks, like taking up space. Overall, though, they’re a great choice for homeowners.

Design Principles of Shell and Tube Heat Exchanger Refrigeration Systems

Okay, now let’s talk about what goes into designing a shell and tube heat exchanger refrigeration system. There’s a lot to consider, but we’ll break it down into bite-sized chunks for you.

Selection of Materials

Choosing the right materials for your heat exchanger is crucial. You want something that’s durable, corrosion-resistant, and can handle the temperature and pressure of the fluids you’re working with. A popular choice is stainless steel, known for its strength and resistance to rust.

Tube Configuration and Arrangement

The way the tubes are arranged inside the shell is super important too. You’ll need to think about the shape, spacing, and layout of the tubes, as well as the design of the baffles (those things that help direct the flow of fluid). It’s like a puzzle, but one that’s definitely worth solving!

Shell and Tube Side Fluid Selection

Now let’s talk about the fluids that flow through your heat exchanger. You’ll need to choose ones that are compatible and can handle the temperature and pressure conditions. And, of course, you’ll want something that’s efficient in terms of heat transfer.

Refrigerants

Refrigerants are the substances that make the magic of cooling happen. There are a bunch of options out there, but it’s essential to choose one that’s environmentally friendly and safe. Remember, we’re all in this together!

Performance and Efficiency Optimization

Now that you’ve got the basics down, let’s talk about optimizing your shell and tube heat exchanger refrigeration system. After all, we’re all about efficiency, right?

Heat Transfer Coefficient Enhancement

Boosting the heat transfer coefficient is key. One way to do that is by adding extended surfaces or fins to the tubes. Another is by using turbulators, which mix up the fluid flow and improve heat transfer. Sounds like a winning combination to us!

Fouling and Scaling Prevention

Nobody wants a dirty heat exchanger, right? Fouling and scaling can reduce your system’s efficiency, so it’s essential to choose the right fluids and keep up with regular maintenance and cleaning. Think of it like brushing your teeth – a little effort goes a long way!

Pressure Drop Minimization

Pressure drop is a bit of a balancing act. You want to minimize it without sacrificing heat transfer. How? By choosing the optimal tube and baffle spacing. It’s like finding the sweet spot between two competing factors.

Applications of Shell and Tube Heat Exchanger Refrigeration

Now you might be wondering, where can you use shell and tube heat exchanger refrigeration? Well, you’re in luck! There are a ton, and we’re going to cover some of the most relevant ones for homeowners like you.

Industrial Refrigeration

While industrial refrigeration might not seem relevant to homeowners, it’s actually where a lot of the technology and innovation comes from. Applications include food and beverage processing, as well as chemical and petrochemical industries. So, next time you enjoy a cold drink, remember the role of shell and tube heat exchangers!

HVAC Systems

Now we’re talking! Shell and tube heat exchanger refrigeration is perfect for commercial and residential air conditioning. Plus, it can be used in heat recovery systems, helping you save energy and reduce your carbon footprint. A win-win situation for both you and the environment.

Marine and Offshore Systems

Another fascinating application is in marine and offshore systems, like shipboard refrigeration and cooling systems on offshore oil and gas platforms. So, while you might not be sailing the high seas, it’s good to know that these heat exchangers can handle some pretty demanding environments!

Maintenance and Troubleshooting

Let’s face it, things don’t always go as planned. That’s why it’s essential to know how to maintain and troubleshoot your shell and tube heat exchanger refrigeration system.

Inspection and Cleaning

Periodic inspections are crucial for keeping your system running smoothly. And when it comes to cleaning, there are various methods available, like chemical cleaning and high-pressure water jetting. Choose the one that’s right for your specific situation, and you’ll be good to go.

Common Issues and Solutions

Some common problems with shell and tube heat exchangers include fouling, scaling, corrosion, erosion, leakage, and seal issues. But don’t worry! There are solutions for each of these issues, and with proper maintenance, you can keep them at bay.

Future Trends and Developments

Finally, let’s take a quick peek into the future of shell and tube heat exchanger refrigeration. What exciting developments are on the horizon?

Advanced Materials and Coatings

One area to watch is the development of advanced materials and coatings, like nanotechnology and smart materials. These could help improve efficiency, reduce fouling, and increase the lifespan of your heat exchanger.

Energy Recovery and Efficiency

Another promising trend is the focus on energy recovery and efficiency. Waste heat recovery systems and the integration of renewable energy sources could make shell and tube heat exchanger refrigeration even more eco-friendly.

Environmental and Sustainability Considerations

Last but not least, there’s a growing emphasis on environmental and sustainability considerations. This includes the development of low-global warming potential refrigerants and efforts to reduce greenhouse gas emissions. It’s all about creating a greener future for everyone!

And there you have it, a complete guide to shell and tube heat exchanger refrigeration for homeowners. So, why not consider installing one in your home and enjoy the benefits of a cool, comfortable, and energy-efficient living space?