If you’re looking for information about the types of expansion valve in refrigeration system, you’ve come to the right place. This guide explores various expansion valve types, their functions, how they work, and when to use them.

Table of Contents

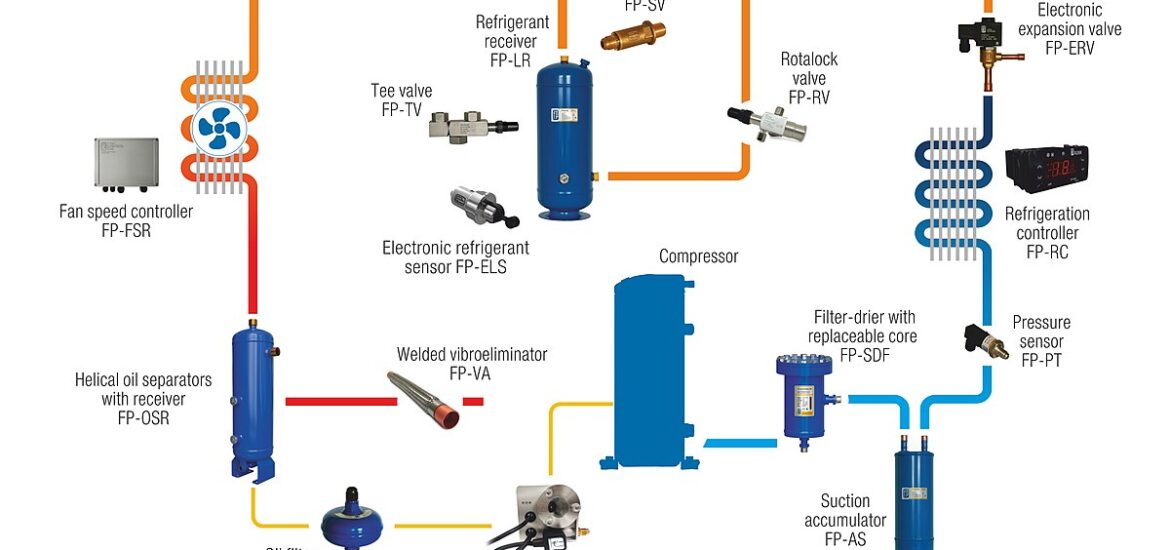

Types of Expansion Valve in Refrigeration System

In the complex world of refrigeration, expansion valves hold a pivotal role. Understanding the different types of expansion valve in refrigeration system can empower you to make informed decisions, whether for personal or professional use. Here’s an in-depth look at the various types:

1. Thermostatic Expansion Valves (TXV)

The Thermostatic Expansion Valve (TXV) is a sophisticated valve that regulates the flow of refrigerant based on the evaporator’s temperature. It consists of a sensing bulb, diaphragm, and spring mechanism:

Function: The TXV senses the temperature at the evaporator’s outlet and adjusts the refrigerant flow accordingly. The sensing bulb transmits pressure to the diaphragm, controlling the valve opening.

Applications: Widely used in commercial and industrial refrigeration, air conditioning, and heat pump systems.

Advantages: Offers precise control, adapts to varying conditions, and improves energy efficiency.

Disadvantages: More complex and expensive than other valves. Requires proper installation and maintenance.

2. Automatic Expansion Valves (AXV)

Automatic Expansion Valves (AXV) are simpler devices that control the flow based on the evaporator’s pressure:

Function: The AXV maintains a constant pressure in the evaporator by automatically adjusting the refrigerant flow. It reacts to pressure changes but doesn’t consider temperature.

Applications: Suitable for smaller systems or where precise temperature control is not critical.

Advantages: Simplicity, reliability, and lower cost compared to TXVs.

Disadvantages: Less accurate and adaptable, may lead to less efficient operation under varying conditions.

3. Electronic Expansion Valves (EXV)

Electronic Expansion Valves (EXV) represent the cutting edge in valve technology, utilizing electronic controls for precise operation:

Function: The EXV is controlled by a microprocessor that receives inputs from various sensors to modulate the refrigerant flow based on multiple parameters such as pressure, temperature, and humidity.

Applications: Ideal for advanced and complex refrigeration systems requiring high precision and adaptability.

Advantages: Highly accurate, energy-efficient, can be remotely monitored and controlled.

Disadvantages: More expensive and complex, requiring specialized knowledge for installation and maintenance.

4. Capillary Tubes

Though not technically a valve, capillary tubes serve as expansion devices in many refrigeration systems:

Function: Capillary tubes are narrow tubes that restrict the flow of refrigerant based on their length and diameter. The constriction creates a pressure drop, controlling the refrigerant flow.

Applications: Commonly found in small appliances like household refrigerators and window air conditioners.

Advantages: Simplicity, low cost, and ease of installation.

Disadvantages: Fixed flow control, not adaptable to changing conditions, may become clogged or damaged more easily.

If you need a refrigerator for your home, office, or dorm, you can check out this Upstreman 3.2 Cu.Ft Mini Fridge with Freezer on Amazon.

Check out these other related articles…

Electronic Expansion Valve Controller: A Comprehensive Guide

What is Expansion Valve? Your Ultimate Guide

Expansion Valve Symptoms: A Comprehensive Guide

Expansion Valve Bulb Position: A Comprehensive Guide

Expansion Valve vs Capillary Tube: A Detailed Comparison

Choosing the Right Expansion Valve

Selecting the right expansion valve involves understanding the specific needs of the refrigeration system, such as its size, complexity, and desired precision. The following factors are essential to consider:

System Requirements: Determine the cooling capacity, pressure, and temperature ranges.

Budget Considerations: Balance between cost and performance needs.

Efficiency Needs: Analyze energy consumption and select an option that aligns with energy-saving goals.

Maintenance: Consider the ease of maintenance, especially in complex systems.