Expansion valve thermodynamics plays a vital role in many cooling systems and processes. Whether you are a student, a technician, or someone simply curious about this subject, this article will guide you through the fundamentals, its working in chillers, and much more.

Table of Contents

What is Expansion Valve Thermodynamics?

The expansion valve is a critical component within the thermodynamics of a refrigeration or air conditioning system. It’s the part that controls the flow of refrigerant into the evaporator, and its working can be broken down into the following key aspects:

Pressure Reduction

The expansion valve restricts the flow of the refrigerant, causing a drop in pressure. This drop is vital because it transforms the refrigerant from a high-pressure liquid into a low-pressure mixture of liquid and vapor. The low pressure allows the refrigerant to absorb heat from the environment in the subsequent stages of the cooling cycle.

Temperature Control

Along with the drop in pressure, there is a corresponding decrease in temperature. The lower temperature ensures that the refrigerant is at the correct state to efficiently absorb heat within the evaporator. Any deviation in this temperature can lead to inefficiencies and reduced cooling performance.

Flow Regulation

The valve’s ability to regulate the flow is crucial in maintaining the balance between too much refrigerant (flooding) and too little (starvation) within the evaporator. Flooding can cause compressor damage, while starvation can lead to inadequate cooling. The expansion valve maintains this balance by constantly adjusting to changes in operating conditions.

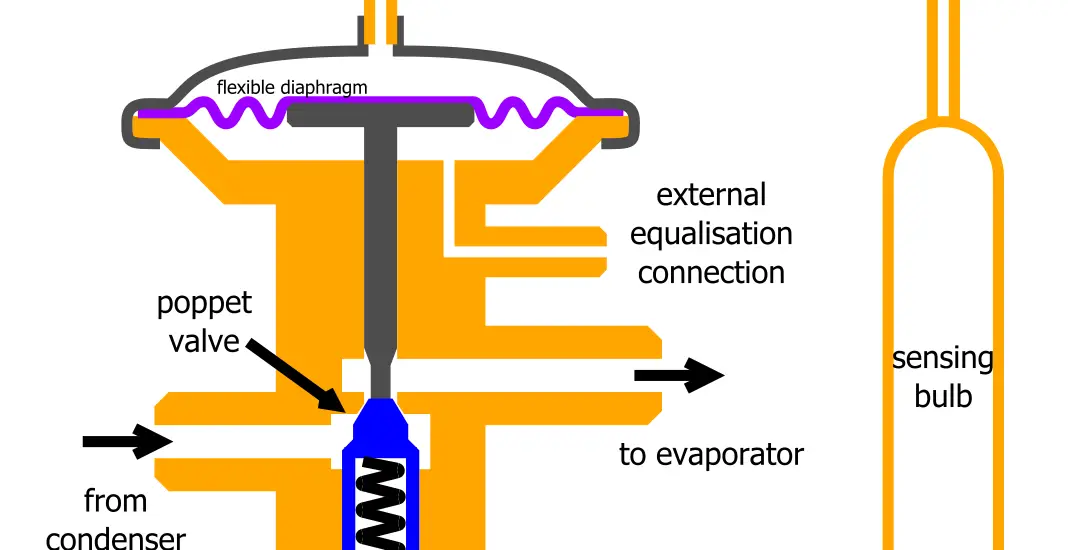

Types and Construction

Expansion valves can be mechanical or electronic, and they vary in construction and operation. The valve typically consists of a body, diaphragm, spring, and other components that work together to achieve precise control over the refrigerant flow. It may also contain temperature-sensing elements that help in adapting to changes in the system.

Check out these other related articles…

How to Test Expansion Valve in 6 Easy Steps

Expansion Valve Troubleshooting: 4 Easy Steps to Follow

Electronic Expansion Valve Controller: A Comprehensive Guide

What is Expansion Valve? Your Ultimate Guide

Expansion Valve Symptoms: A Comprehensive Guide

Expansion Valve Working in Chiller

The working of the expansion valve in a chiller is an essential aspect of the refrigeration cycle. It’s instrumental in controlling the cooling process and ensuring efficiency. Here’s a detailed step-by-step explanation:

After Compressor

Once the refrigerant exits the compressor as a hot, high-pressure gas, it passes through the condenser. Here, it releases its heat to the surrounding medium (air or water) and transforms into a high-pressure liquid. This process prepares the refrigerant for the expansion valve.

Before Evaporator

The high-pressure liquid refrigerant enters the expansion valve, where its pressure and temperature are significantly reduced. This transformation is vital as it prepares the refrigerant to absorb heat from the space that needs to be cooled (inside the evaporator).

Controlling Flow

The valve’s precise control over the flow ensures that the right amount of refrigerant enters the evaporator at any given time. This control is achieved through a combination of mechanical adjustments and sensory feedback from the system. It ensures that the chiller operates efficiently and maintains the desired temperature without overcooling or undercooling.

Adaptation to Load Changes

Chillers often operate under varying load conditions. The expansion valve adapts to these changes by adjusting the refrigerant flow accordingly. This adaptability ensures consistent performance and energy efficiency, even as the cooling requirements fluctuate.

Integration with Other Components

The expansion valve’s function is closely tied to other components within the chiller, such as the compressor, condenser, and evaporator. Any changes in one part can affect the valve’s operation, and hence, it requires careful calibration and coordination with the rest of the system for optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the expansion valve is vital for system efficiency. Here’s what to look for:

Checking for Leaks: Ensure that there are no leaks that could cause a loss of refrigerant.

Inspecting for Obstructions: Check for dirt or debris that could restrict the flow of refrigerant.

Calibration: Ensure that the valve is calibrated correctly, as improper calibration can lead to inefficient cooling.

Professional Assistance: For more complex issues, seek professional help to ensure that the system continues to operate safely and efficiently.