This guide will break down everything you need to know about expansion valve types to ensure you have a solid grasp of this topic.

Table of Contents

The Importance of Knowing Expansion Valve Types

It’s worth noting that not all expansion valves are created equal. Different expansion valve types are designed to work best under specific conditions and in certain systems. Having a clear understanding of the types of expansion valves available allows you to make an informed decision about which one is most suitable for your specific application.

The 7 Types of Expansion Valves

There are various types of expansion valves, each with its unique characteristics and best uses. This section provides a detailed overview of the seven common types of expansion valves you might encounter.

1. Thermal Expansion Valves (TXV)

Thermal Expansion Valves, also known as TXVs, are among the most popular types of expansion valves. These valves adjust the amount of refrigerant entering the evaporator based on the cooling load. This adjustment is made possible through a temperature-sensing bulb filled with a refrigerant-charged liquid, which is attached to the suction line.

As the temperature changes, the pressure within the bulb alters, adjusting the valve opening accordingly. This allows for high efficiency and consistent evaporator temperature, making TXVs particularly well-suited for systems with fluctuating loads.

2. Automatic Expansion Valves (AXV)

Automatic Expansion Valves, or AXVs, are designed to maintain a constant pressure in the evaporator regardless of the load on the system. They achieve this by sensing the pressure in the evaporator and adjusting the refrigerant flow accordingly.

AXVs are usually used in smaller, simpler systems where the load remains relatively constant, such as domestic refrigerators and freezers.

3. Electronic Expansion Valves (EXV)

Electronic Expansion Valves, abbreviated as EXVs, use electronic controllers to adjust the refrigerant flow based on various system variables, such as pressure and temperature. This allows for precise control of the refrigerant flow, ensuring optimal system performance.

EXVs are commonly found in large, complex systems where load conditions frequently change, such as commercial air conditioning systems.

4. Capillary Tubes

Capillary tubes aren’t technically valves, but they serve a similar purpose. They’re simply long, narrow tubes through which the refrigerant passes. The small diameter and length of the tube cause a significant pressure drop, which controls the refrigerant flow rate.

Because they are simple and inexpensive, capillary tubes are often used in small, non-adjustable load systems like window air conditioners.

Check out these other related articles…

Expansion Valve in AC: Your Comprehensive Guide

Electronic Expansion Valve: Your Easy Guide

Expansion Valve in Refrigerator: Your Easy 101 Guide

Expansion Valve Function: Easy 101 Guide

Expansion Valve Chiller: Your Quick 101 Guide

5. Float Type Valves

Float-type valves control the flow of refrigerant based on the liquid refrigerant level in the low-pressure side of the system. There are two main types of float valves: low-side float valves, which are located in the low-pressure receiver, and high-side float valves, located in the high-pressure receiver.

Low-side float valves are typically used in commercial refrigeration systems, while high-side float valves are often used in centrifugal chillers.

6. Internally Equalized Valves

Internally Equalized Valves are a type of TXV designed to sense pressure at the outlet of the evaporator coil. These valves are most effective when there’s no significant pressure drop across the evaporator.

They’re commonly found in smaller refrigeration and air conditioning systems.

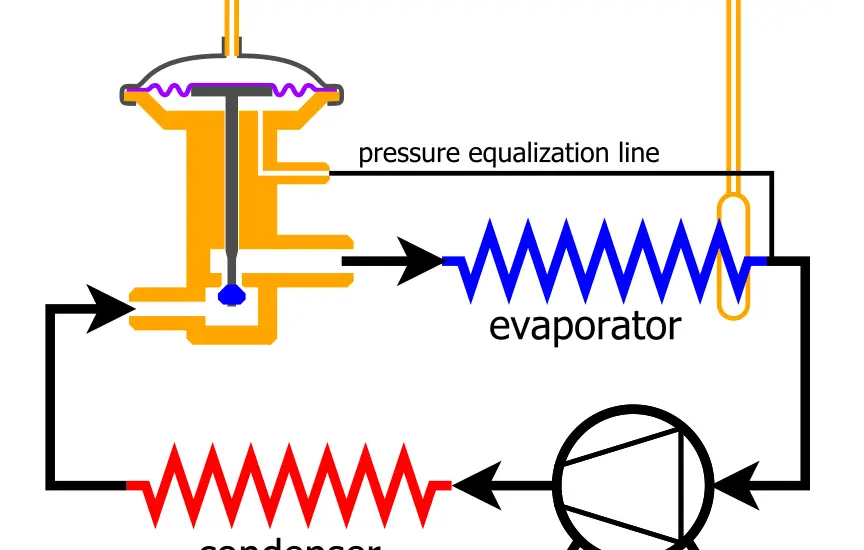

7. Externally Equalized Valves

Externally Equalized Valves, another subtype of TXV, are used when there’s a substantial pressure drop in the evaporator. These valves feature an extra external equalizer line that connects to the evaporator outlet. This additional line allows the valve to compensate for the pressure drop, ensuring the refrigerant flow is accurately controlled.

Externally equalized valves are typically found in larger systems with multiple evaporator coils or long refrigerant lines.