Knowing how to unclog expansion valve is essential for maintaining optimal system performance. Whether you’re troubleshooting an HVAC system or a refrigeration unit, this guide provides comprehensive, step-by-step instructions to ensure that even complete beginners can navigate the process effectively.

Table of Contents

Step-by-Step Guide: How to Unclog Expansion Valve

Follow the steps below to unclog the expansion valve:

1. Prioritize Safety

Your safety is paramount when dealing with mechanical or electrical systems. Before attempting to unclog an expansion valve:

Power Down: Always turn off the system and disconnect it from the electrical outlet to eliminate the risk of electrical shocks.

Wear Protective Gear: Use gloves to protect your hands from sharp edges or debris. Safety goggles are essential too, as they prevent any foreign particles from getting into your eyes, especially during the cleaning process.

Work in a Well-lit Environment: Ensure the area you’re working in is well-lit, so you clearly see and handle components, reducing the chances of errors or mishaps.

2. Locate and Access the Valve

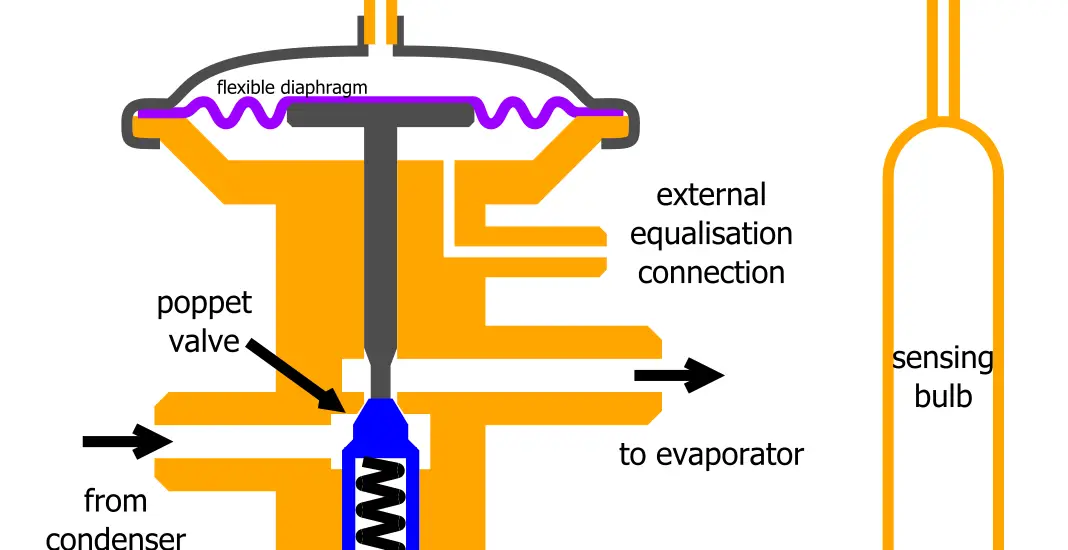

The expansion valve, a critical component in refrigeration and air conditioning systems, might be hidden or obstructed by panels or casings. Here’s how to find it:

Consult the Manual: Most systems come with a user or repair manual that contains diagrams indicating the position of major components. Use this as your first reference point.

Search Near the Evaporator: Generally, the expansion valve is located close to the evaporator coil. By identifying the coil, you can quickly locate the valve.

Remove Obstructions: If the valve is behind a panel or a protective cover, use appropriate tools, usually a screwdriver, to gently remove the obstruction.

3. Inspect the Valve

Before you proceed to clean, it’s vital to assess the condition of the expansion valve:

Visual Inspection: Look for any signs of visible blockages, dirt, or debris. Accumulated dust or particles can often be the main culprits.

Check for Damage: While you’re at it, also inspect the valve for any signs of wear, tear, or damage. A damaged valve might need more than just cleaning.

Utilize a Flashlight: A flashlight will help you peer into small orifices or darker areas, ensuring a thorough inspection.

4. Thoroughly Clean the Valve

If you determine that the valve needs a deeper cleaning, carefully remove it as per the manufacturer’s guidelines. Use a mild solvent or a cleaner specifically designed for such components. Employ a soft brush to gently scrub away any obstructions, ensuring all small openings and pathways are clear. After cleaning, rinse the valve with distilled water and let it dry completely.

5. Reassemble and Secure the Valve

With the valve cleaned, carefully place it back into its original position. Ensure all connections are tight, and there are no loose parts. Replace any panels or covers you removed during the initial stages.

6. Test the System’s Performance

After reassembling everything, plug the unit back into the power source and turn it on. Monitor its performance over the next few hours. The cooling or heating efficiency should improve. If the problem persists or if you notice any unusual noises, consider consulting a professional.

Check out these other related articles…

How Does an Expansion Valve Work: Your Easy 101 Guide

Expansion Valve Adjustment in 6 Easy Steps

Expansion Valve Orifice: A Comprehensive Guide

Electronic Expansion Valve Troubleshooting: Easy 411 Guide

How to Replace Expansion Valve: The Ultimate DIY Guide

Symptoms of a Clogged Expansion Valve

A malfunctioning expansion valve can manifest in various ways. Being vigilant about the following signs can help in early detection and timely intervention:

Reduced cooling or heating efficiency: A noticeable decline in the system’s ability to cool or heat might indicate a clogged valve.

Noise or hissing sound: Any unusual noises, particularly a hissing sound, might be a result of the refrigerant struggling to pass through the clogged valve.

Frequent cycling: If the system turns on and off more frequently than usual, the clogged valve might be restricting the flow of the refrigerant, causing the system to overwork.