Understanding the thermostatic expansion valve in a refrigeration system is essential for anyone dealing with cooling appliances. In this guide, we will break down its operation, maintenance, and troubleshooting in clear, simple terms for both professionals and novices alike.

Table of Contents

What Is a Thermostatic Expansion Valve in a Refrigeration System?

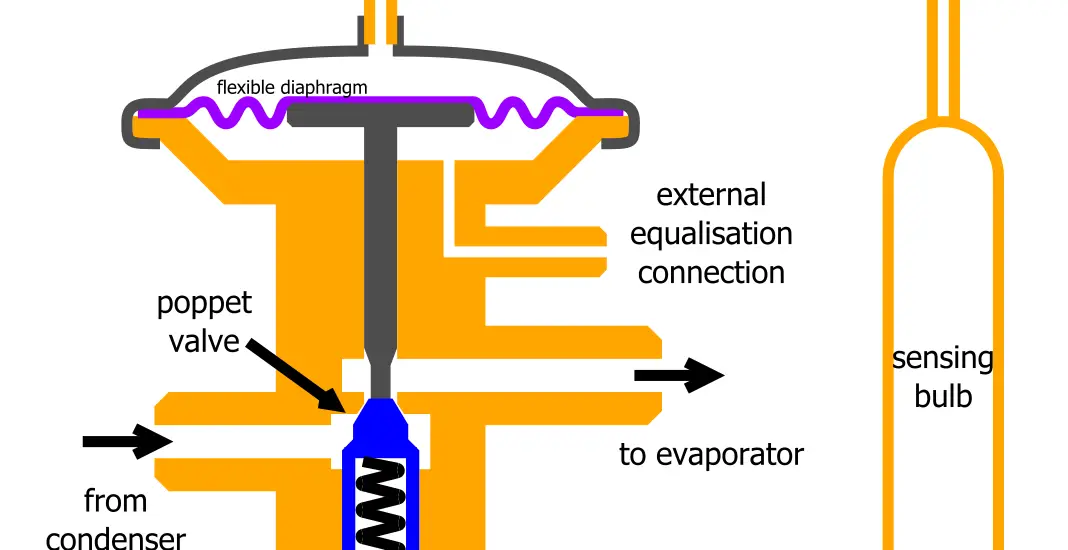

The thermostatic expansion valve (TEV or TXV) is a crucial control device located in the refrigeration system. Let’s break down its characteristics:

Location: Positioned between the liquid line and the evaporator inlet, it serves as a gateway for the refrigerant.

Function: The primary purpose is to control the flow of refrigerant into the evaporator. It does this by reacting to changes in pressure and temperature within the system, ensuring the correct amount of refrigerant is provided to the evaporator.

Components: A TEV consists of several essential parts, including a valve body, a diaphragm, a temperature-sensing bulb, and springs. Each part plays a vital role in the valve’s operation.

Importance: The thermostatic expansion valve in a refrigeration system is responsible for maintaining the balance between the liquid and vapor refrigerant. A failure or malfunction in the valve can cause inefficiency and even the breakdown of the entire system.

How Does a Thermostatic Expansion Valve in a Refrigeration System?

The operation of the thermostatic expansion valve in a refrigeration system is complex but can be understood by breaking it down into the following steps:

Sensing Temperature: The temperature sensing bulb, filled with a substance that reacts to temperature changes, is attached to the evaporator outlet. If the temperature rises, the substance expands, exerting pressure on the diaphragm.

Adjusting Flow: This pressure on the diaphragm triggers the valve to open, allowing more refrigerant into the evaporator. Conversely, if the temperature drops, the pressure decreases, causing the valve to close partially and restrict the refrigerant flow.

Maintaining Balance: The thermostatic expansion valve in a refrigeration system constantly adjusts to keep the right balance between liquid and vapor refrigerant, based on the cooling demand. By doing so, it ensures that the evaporator is neither flooded nor starved, allowing the refrigeration system to work efficiently.

Maintenance of a Thermostatic Expansion Valve

Regular and correct maintenance of the thermostatic expansion valve is vital for the refrigeration system’s optimal performance. Here’s how you can perform maintenance:

Regular Inspections: Keep an eye on the valve for signs of leaks, rust, or wear. Early detection can prevent larger problems.

Cleaning: Regular cleaning with appropriate solvents helps in removing any buildup that might lead to blockages.

Part Replacement: Inspect for worn parts and replace them promptly. Even a small worn-out part can affect the entire system’s functionality.

Professional Assistance: Always consult a professional technician if the valve appears complex or if any repair seems beyond your expertise. Incorrect handling can cause further damage.

Check out these other related articles…

What is Expansion Valve? Your Ultimate Guide

Expansion Valve Symptoms: A Comprehensive Guide

Expansion Valve Bulb Position: A Comprehensive Guide

Expansion Valve vs Capillary Tube: A Detailed Comparison

Expansion Valve Thermodynamics: A Comprehensive 411 Guide

Expansion Valve Working Principle: A Comprehensive Guide

Types of Expansion Valve in Refrigeration System: Easy Guide

Common Issues and Troubleshooting

The thermostatic expansion valve in a refrigeration system may experience several common issues. Here are the problems and solutions:

Sticking or Clogging: Debris or buildup may cause the valve to stick or clog. Regular cleaning and inspection can prevent this problem. If stuck, gentle tapping might help, but avoid excessive force.

Temperature Sensing Bulb Failure: If the temperature sensing bulb fails, the valve cannot sense the correct temperature, affecting its operation. Replacement with a compatible bulb is the solution.

Incorrect Superheat Setting: If the superheat setting is wrong, it may cause either flooding or starving of the evaporator. Correct calibration by following the manufacturer’s guidelines or consulting a technician is necessary.

Complex Issues: For more complicated problems that are hard to diagnose, it is always wise to consult a professional technician. Trying to fix them without proper knowledge might worsen the situation.